Today's Lesson: Interlocking Parts

What is it?

Every material has some inherent strength due to intermolecular bonds, microstructure, or interactions between different phases in a composite material. Simply stated, a material fails (deforms) when the stress in the material exceeds some critical stress value. The stress a material is under is expressed as a Force per Area. Thus a part with a larger cross section can withstand a larger force.Buckling

Many parts used in structural applications have a large aspect ratio (ratio of length to width). If a long slender part is put under compression, it is likely to buckle. Buckling occurs when a part deforms long before the plastic limit is reached. This is easy to demonstrate with a flexible ruler, a straw, or a toothpick. If you try to compress it along the long axis it will bow out and fail to support the load.Fcrit=(π2EI)/(KL)2

where E is the modulus of Elasticity

I is the area moment of inertia

L is the length of the column

K is a factor that depends on how the part is supported.

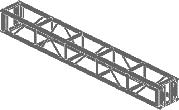

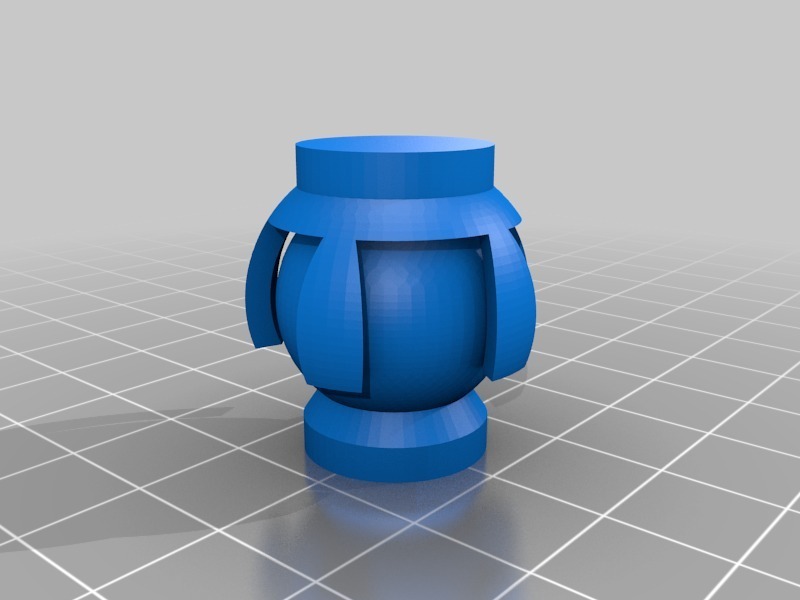

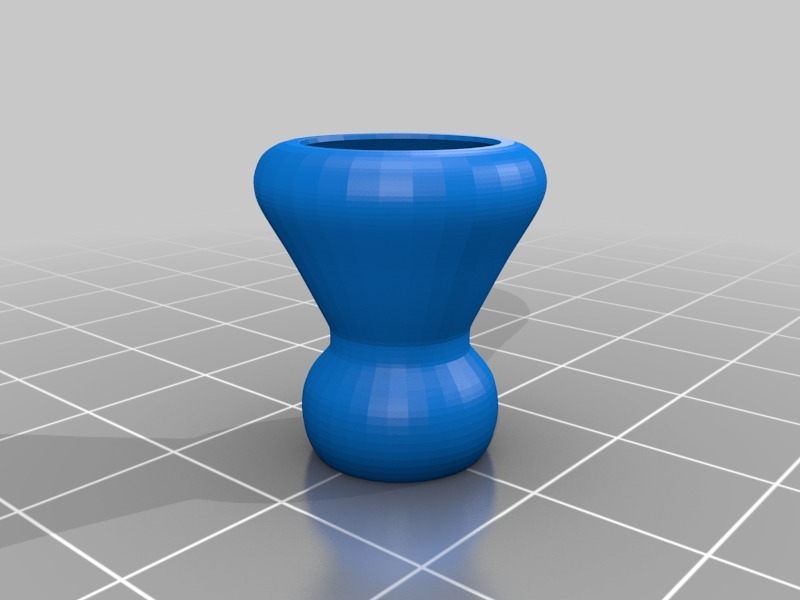

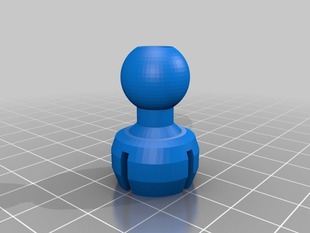

This equation reveals that buckling can be avoided by choosing a stiffer material, decreasing the length, or by increasing the area moment of inertia. Thus if you are designing a tube, try increasing the radius a little to increase the area moment. Buckling can also be avoided by using thinner parts to stiffen a long, flexible frame, as shown below:

|

|

|

| thing:1968 | thing:17021 | thing:5578 |

Challenge

Build the highest structure possible.Design joints and nodes to connect parts together.

Your tower must stand without assistance.

You cannot use glue or other types of adhesives.

Helpful hints

For a part that needs to fit tightly within another part, design them so that they have 0.25mm clearance on all sides.(You may have to test this, as shrinkage occurs and your printing may be different).For a part that must easily slide within another part, design them so that they have 0.5mm clearance on all sides.

1 millimeter = 0.0393700787 inches

Bonus points are awarded for aesthestic design and the best named tower.

- Design Step 1: Identify the Need

- Design Step 2: Research the Problem

- Design Step 3: Brainstorm Possible Solutions

- Design Step 4: Engineering Analysis-select the most promising solution

- Design Step 5: Construct a Prototype

- Design Step 6: Evaluate/Manufacture a Final Product-Reiterate

Document

What to include?- Sketches

- CAD files

- Goals

- Prototypes

- Diagrams

- Analysis

- Testing

Standards

Mathematics, Science, and Technology

-

STANDARD 1

Analysis, Inquiry, and Design: ENGINEERING DESIGN

Key Idea 1: details

Engineering design is an iterative process involving modeling and optimization (finding the best solution within given constraints); this process is used to develop technological solutions to problems within given constraints. (Note: The design process could apply to activities from simple investigations to long-term projects.)Elementary 1.1 Describe objects, imaginary or real, that might be modeled or made differently and suggest ways in which the objects can be changed, fixed, or improved √ 1.2 Investigate prior solutions and ideas from books, magazines, family, friends, neighbors, and community members √ 1.3 Generate ideas for possible solutions, individually and through group activity; apply age-appropriate mathematics and science skills; evaluate the ideas and determine the best solution; and explain reasons for the choices √ 1.4 Plan and build, under supervision, a model of the solution using familiar materials, processes, and hand tools √ 1.5 Discuss how best to test the solution; perform the test under teacher supervision; record and portray results through numerical and graphic means; discuss orally why things worked or didn't work; and summarize results in writing, suggesting ways to make the solution better √

Intermediate T1.1 Identify needs and opportunities for technical solutions from an investigation of situations of general or social interest. √ T1.1a Identify a scientific or human need that is subject to a technological solution which applies scientific principles √ T1.2 Locate and utilize a range of printed, electronic, and human information resources to obtain ideas. √ T1.2a Use all available information systems for a preliminary search that addresses the need. √ T1.3 Consider constraints and generate several ideas for alternative solutions, using group and individual ideation techniques (group discussion, brainstorming, forced connections, role play); defer judgment until a number of ideas have been generated; evaluate (critique) ideas; and explain why the chosen solution is optimal. √ T1.3a Generate ideas for alternative solutions √ T1.3b Evaluate alternatives based on the constraints of design √ T1.4 Develop plans, including drawings with measurements and details of construction, and construct a model of the solution, exhibiting a degree of craftsmanship. √ T1.4a Design and construct a model of the product or process √ T1.4b Construct a model of the product or process √ T1.5 In a group setting, test their solution against design specifications, present and evaluate results, describe how the solution might have been modified for different or better results, and discuss trade-offs that might have to be made. √ T1.5a Test a design √ T1.5b Evaluate a design √

Commencement 1.1 Initiate and carry out a thorough investigation of an unfamiliar situation and identify needs and opportunities for technological invention or innovation √ 1.2 identify, locate, and use a wide range of information resources including subject experts, library references, magazines, videotapes, films, electronic data bases and online services, and discuss and document through notes and sketches how findings relate to the problem 1.3 generate creative solution ideas, break ideas into the significant functional elements, and explore possible refinements; predict possible outcomes using mathematical and functional modeling techniques; choose the optimal solution to the problem, clearly documenting ideas against design criteria and constraints; and explain how human values, economics, ergonomics, and environmental considerations have influenced the solution √ 1.4 develop work schedules and plans which include optimal use and cost of materials, processes, time, and expertise; construct a model of the solution, incorporating developmental modifications while working to a high degree of quality (craftsmanship) √ 1.5 in a group setting, devise a test of the solution relative to the design criteria and perform the test; record, portray, and logically evaluate performance test results through quanitative, graphic, and verbal means; and use a variety of creative verbal and graphic techniques effectively and persuasively to present conclusions, predict impacts and new problems, and suggest and pursue modifications -

STANDARD 2

INFORMATION SYSTEMS

Key Idea 1: details

Information technology is used to retrieve, process, and communicate information as a tool to enhance learning.Elementary 1.1 Use computer technology,traditional paper-based resources,and interpersonal discussions to learn, do, and share science in the classroom √ 1.2 Select appropriate hardware and software that aids in wordprocessing, creating databases, telecommunications, graphing, data display, and other tasks √ 1.3 Use information technology to link the classroom to world events

Intermediate 1.1 Use a range of equipment and software to integrate several forms of information in order to create good-quality audio, video, graphic, and text-based presentations. 1.2 Use spreadsheets and database software to collect, process, display, and analyze information. Students access needed information from electronic databases and on-line telecommunication services. 1.3 Systematically obtain accurate and relevant information pertaining to a particular topic from a range of sources, including local and national media, libraries, muse- ums, governmental agencies, industries, and individuals. 1.4 Collect data from probes to measure events and phenomena. 1.4a Collect the data, using the appropriate, available tool 1.4b Organize the data 1.4c Use the collected data to communicate a scientific concept √ 1.5 Use simple modeling programs to make predictions.

Physics 1.1 Understand and use the more advanced features of word processing, spreadsheets, and database software. 1.2 Prepare multimedia presentations demonstrating a clear sense of audience and purpose. (Note: Multimedia may include posters, slides, images, presentation software, etc.) √ 1.2a Extend knowledge of physical phenomena through independent investigation, e.g., literature review, electronic resources, library research 1.2b Use appropriate technology to gather experimental data, develop models,and present results √ 1.3 Access, select, collate, and analyze information obtained from a wide range of sources such as research databases, foundations, organizations, national libraries, and electronic communication networks, including the Internet. 1.3a Use knowledge of physics to evaluate articles in the popular press on contemporary scientific topics 1.4 Utilize electronic networks to share information. √ 1.5 Model solutions to a range of problems in mathematics, science, and technology, using computer simulation software. √ 1.5a Use software to model and extend classroom and laboratory experiences,recognizing the differences between the model used for understanding and real-world behavior √ -

STANDARD 5

Technology: Engineering Design

Key Idea 1:details

Engineering design is an iterative process involving modeling and optimization used to develop technological solutions to problems within given constraints.Elementary T1.1 Describe objects, imaginary or real, that might be modeled or made differently and suggest ways in which the objects can be changed, fixed, or improved. √ T1.2 Investigate prior solutions and ideas from books, magazines, family, friends, neighbors, and community members. √ T1.3 Generate ideas for possible solutions, individually and through group activity; apply age-appropriate mathematics and science skills; evaluate the ideas and determine the best solution; and explain reasons for the choices. √ T1.4 Plan and build, under supervision, a model of the solution using familiar materials, processes, and hand tools √ T1.5 Discuss how best to test the solution; perform the test under teacher supervision; record and portray results through numerical and graphic means; discuss orally why things worked or didn't work; and summarize results in writing, suggesting ways to make the solution better. √

Intermediate T1.1 Identify needs and opportunities for technical solutions from an investigation of situations of general or social interest. √ T1.2 Locate and utilize a range of printed, electronic, and human information resources to obtain ideas. √ T1.3 Consider constraints and generate several ideas for alternative solutions, using group and individual ideation techniques (group discussion, brainstorming, forced connections, role play); defer judgment until a number of ideas have been generated; evaluate (critique) ideas; and explain why the chosen solution is optimal. √ T1.4 Develop plans, including drawings with measurements and details of construction, and construct a model of the solution, exhibiting a degree of craftsmanship. √ T1.5 In a group setting, test their solution against design specifications, present and evaluate results, describe how the solution might have been modified for different or better results, and discuss tradeoffs that might have to be made. √

Commencement T1.1 Initiate and carry out a thorough investigation of an unfamiliar situation and identify needs and opportunities for technological invention or innovation. √ T1.2 Identify, locate, and use a wide range of information resources including subject experts, library references, magazines, videotapes, films, electronic data bases and on-line services, and discuss and document through notes and sketches how findings relate to the problem. T1.3 Generate creative solution ideas, break ideas into the significant functional elements, and explore possible refinements; predict possible outcomes using mathematical and functional modeling techniques; choose the optimal solution to the problem, clearly documenting ideas against design criteria and constraints; and explain how human values, economics, ergonomics, and environmental considerations have influenced the solution. √ T1.4 Develop work schedules and plans which include optimal use and cost of materials, processes, time, and expertise; construct a model of the solution, incorporating developmental modifications while working to a high degree of quality (craftsmanship). √ T1.5 In a group setting, devise a test of the solution relative to the design criteria and perform the test; record, portray, and logically evaluate performance test results through quantitative, graphic, and verbal means; and use a variety of creative verbal and graphic techniques effectively and persuasively to present conclusions, predict impacts and new problems, and suggest and pursue modifications. -

STANDARD 5

Technology: Engineering Design

Key Idea 2: details

Technological tools, materials, and other resources should be selected on the basis of safety, cost, availability, appropriateness, and environmental impact; technological processes change energy, information, and material resources into more useful forms.Elementary 2.1 Explore, use, and process a variety of materials and energy sources to design and construct things. √ 2.2 Understand the importance of safety, cost, ease of use, and availability in selecting tools and resources for a specific purpose. 2.3 Develop basic skill in the use of hand tools 2.4 Use simple manufacturing processes (e.g., assembly, multiple stages of production, quality control) to produce a product √ 2.5 Use appropriate graphic and electronic tools and techniques to process information. √

Intermediate 2.1 Choose and use resources for a particular purpose based upon an analysis and understanding of their properties, costs, availability, and environmental impact √ 2.2 Use a variety of hand tools and machines to change materials into new forms through forming, separating, and combining processes, and processes which cause internal change to occur √ 2.3 Combine manufacturing processes with other technological processes to produce, market, and distribute a product 2.4 Process energy into other forms and information into more meaningful information.

Commencement 2.1 Test, use, and describe the attributes of a range of material (including synthetic and composite materials), information, and energy resources √ 2.2 Select appropriate tools, instruments, and equipment and use them correctly to process materials, energy, and information √ 2.3 Explain tradeoffs made in selecting alternative resources in terms of safety, cost, properties, availability, ease of processing, and disposability 2.4 Describe and model methods (including computer-based methods) to control system processes and monitor system outputs √ -

STANDARD 5

Technology: Computer Technology

Key Idea 3: details

Computers, as tools for design, modeling, information processing, communication, and system control, have greatly increased human productivity and knowledge.Elementary 3.1 Identify and describe the function of the major components of a computer system. 3.2 Use the computer as a tool for generating and drawing ideas. √ 3.3 Control computerized devices and systems through programming. √ 3.4 Model and simulate the design of a complex environment by giving direct commands.

Intermediate 3.1 Assemble a computer system including keyboard, central processing unit and disc drives, mouse, modem, printer, and monitor 3.2 Use a computer system to connect to and access needed information from various Internet sites √ 3.3 Use computer hardware and software to draw and dimension prototypical designs √ 3.4 Use a computer as a modeling tool √ 3.5 Use a computer system to monitor and control external events and/or systems √

Commencement 3.1 Understand basic computer architecture and describe the function of computer subsystems and peripheral devices 3.2 Select a computer system that meets personal needs 3.3 Attach a modem to a computer system and telephone line, set up and use communications software, connect to various online networks, including the Internet, and access needed information using email, telnet, gopher, ftp, and web searches 3.4 Use computer-aided drawing and design (CADD) software to model realistic solutions to design problems √ 3.5 Develop an understanding of computer programming and attain some facility in writing computer programs √ -

STANDARD 5

Technology: Impacts of Technology

Key Idea 6: details

Technology can have positive and negative impacts on individuals, society, and the environment and humans have the capability and responsibility to constrain or promote technological development.Elementary 6.1 Describe how technology can have positive and negative effects on the environment and on the way people live and work. √

Intermediate 6.1 Describe how outputs of a technological system can be desired, undesired, expected, or unexpected 6.2 Describe through examples how modern technology reduces manufacturing and construction costs and produces more uniform products

Commencement 6.1 Explain that although technological effects are complex and difficult to predict accurately, humans can control the development and implementation of technology. 6.2 Explain how computers and automation have changed the nature of work 6.3 Explain how national security is dependent upon both military and nonmilitary applications of technology -

STANDARD 5

Technology: Management of Technology

Key Idea 7: details

Project management is essential to ensuring that technological endeavors are profitable and that products and systems are of high quality and built safely, on schedule, and within budget.Elementary 7.1 Participate in small group projects and in structured group tasks requiring planning, financing, production, quality control, and follow-up. √ 7.2 Speculate on and model possible technological solutions that can improve the safety and quality of the school or community environment.

Intermediate 7.1 Manage time and financial resources in a technological project 7.2 Provide examples of products that are well (and poorly) designed and made, describe their positive and negative attributes, and suggest measures that can be implemented to monitor quality during production 7.3 Assume leadership responsibilities within a structured group activity √

Commencement 7.1 Develop and use computer-based scheduling and project tracking tools, such as flow charts and graphs 7.2 Explain how statistical process control helps to assure high quality output 7.3 Discuss the role technology has played in the operation of successful U.S. businesses and under what circumstance they are competitive with other countries 7.4 Explain how technological inventions and innovations stimulate economic competitiveness and how, in order for an innovation to lead to commercial success, it must be translated into products and services with marketplace demand 7.5 Describe new management techniques (e.g., computer-aided engineering, computer-integrated manufacturing, total quality management, just-in-time manufacturing), incorporate some of these in a technological endeavor, and explain how they have reduced the length of design-to-manufacture cycles, resulted in more flexible factories, and improved quality and customer satisfaction 7.6 Help to manage a group engaged in planning, designing, implementation, and evaluation of a project to gain understanding of the management dynamics √ -

STANDARD 6

Interconnectedness: Common Themes SYSTEMS THINKING:

Key Idea 1: details

Through systems thinking, people can recognize the commonalities that exist among all systems and how parts of a system interrelate and combine to perform specific functions.Elementary 1.1 Observe and describe interactions among components of simple systems. √ 1.2 Identify common things that can be considered to be systems (e.g., a plant population, a subway system, human beings).

Intermediate 1.1 Describe the differences between dynamic systems and organizational systems. 1.2 describe the differences and similarities between engineering systems, natural systems, and social systems. 1.3 Describe the differences between open- and closed-loop systems. 1.4 Describe how the output from one part of a system (which can include material, energy, or information) can become the input to other parts.

Commencement 1.1 Explain how positive feedback and negative feedback have opposite effects on system outputs. 1.2 Use an input-process-output-feedback diagram to model and compare the behavior of natural and engineered systems. 1.3 Define boundary conditions when doing systems analysis to determine what influences a system and how it behaves. -

STANDARD 6

Interconnectedness: Common Themes OPTIMIZATION:

Key Idea 6: details

In order to arrive at the best solution that meets criteria within constraints, it is often necessary to make trade-offs.Elementary 6.1 Choose the best alternative of a set of solutions under given constraints. √ 6.2 Explain the criteria used in selecting a solution orally and in writing √

Intermediate 6.1 Determine the criteria and constraints and make trade-offs to determine the best decision. √ 6.2 Use graphs of information for a decision-making problem to determine the optimum solution.

Physics Determine optimal solutions to problems that can be solved using quantitative methods √ -

STANDARD 7

Interdisciplinary Problem Solving STRATEGIES:

Key Idea 2: details

Solving interdisciplinary problems involves a variety of skills and strategies, including effective work habits; gathering and processing information; generating and analyzing ideas; realizing ideas; making connections among the common themes of mathematics, science, and technology; and presenting results.Physics 2.1 Collect,analyze,interpret,and present data,using appropriate tools √ 2.2 When students participate in an extended,culminating mathematics,science,and technology project, then students should: Work effectively—Contributing to the work of a brainstorming group, laboratory partnership, cooperative learning group, or project team; planning procedures; identify and managing responsibilities of team members; and staying on task, whether working alone or as part of a group. √ Gather and process information —Accessing information from printed media, electronic data bases, and community resources and using the information to develop a definition of the problem and to research possible solutions. √ Generate and analyze ideas — Developing ideas for proposed solutions, investigating ideas, collecting data, and showing relationships and patterns in the data. √ Observe common themes—Observing examples of common unifying themes, applying them to the problem, and using them to better understand the dimensions of the problem. √ Realize ideas—Constructing components or models, arriving at a solution, and evaluating the result. √ Present results—Using a variety of media to present the solution and to communicate the results. √

CDOS

- Standard 2: Integrated Learning

details

Students will demonstrate how academic knowledge and skills are applied in the workplace and other settings.

Integrated learning encourages students to use essential academic concepts, facts, and procedures in applications related to life skills and the world of work. This approach allows students to see the usefulness of the concepts that they are being asked to learn and to understand their potential application in the world of work.

Elementary 2.1 Identify academic knowledge and skills that are required in specific occupations 2.2 Demonstrate the difference between the knowledge of a skill and the ability to use the skill 2.3 Solve problems that call for applying academic knowledge and skills. √

Intermediate 2.1 Apply academic knowledge and skills using an interdisciplinary approach to demonstrate the relevance of how these skills are applied in work-related situations in local, state, national, and international communities 2.2 Solve problems that call for applying academic knowledge and skills √ 2.3 Use academic knowledge and skills in an occupational context, and demonstrate the application of these skills by using a variety of communication techniques (e.g., sign language, pictures, videos, reports, and technology).

Commencement 2.1 Demonstrate the integration and application of academic and occupational skills in their school learning, work, and personal lives. √ 2.2 Use academic knowledge and skills in an occupational context, and demonstrate the application of these skills by using a variety of communication techniques (e.g., sign language, pictures, videos, reports, and technology) √ 2.3 Research, interpret, analyze, and evaluate information and experiences as related to academic knowledge and technical skills when completing a career plan. - Standard 3a: Universal Foundation Skills

details

Students will demonstrate mastery of the foundation skills and competencies essential for success in the workplace.

- Basic skills

Basic skills include the ability to read, write, listen, and speak as well as perform arithmetical and mathematical functions.

Elementary 3.1.1 Listen to and read the ideas of others and express themselves both orally and in writing; they use basic mathematical concepts and computations to solve problems. √

Intermediate 3.1.1 Listen to and read the ideas of others and analyze what they hear and read; acquire and use information from a variety of sources; and apply a combination of mathematical operations to solve problems in oral or written form. √

Commencement 3.1.1 Use a combination of techniques to read or listen to complex information and analyze what they hear or read; convey information confidently and coherently in written or oral form; and analyze and solve mathematical problems requiring use of multiple computational skills. √ - Thinking skills

Thinking skills lead to problem solving, experimenting, and focused observation and allow the application of knowledge to new and unfamiliar situations.

Elementary 3.2.1 Use ideas and information to make decisions and solve problems related to accomplishing a task. √

Intermediate 3.2.1 Evaluate facts, solve advanced problems, and make decisions by applying logic and reasoning skills. √

Commencement 3.2.1 Demonstrate the ability to organize and process information and apply skills in new ways. √

- Personal Qualities

Personal qualities generally include competence in self-management and the ability to plan, organize, and take independent action.

Elementary 3.3.1 Demonstrate the personal qualities that lead to responsible behavior. √

Intermediate 3.3.1 Demonstrate the ability to work with others, present facts that support arguments, listen to dissenting points of view, and reach a shared decision. √

Commencement 3.3.1 Demonstrate leadership skills in setting goals, monitoring progress, and improving their performance. √

- Interpersonal Skills

Positive interpersonal qualities lead to teamwork and cooperation in large and small groups in family, social, and work situations.

Elementary 3.4.1 Relate to people of different ages and from diverse backgrounds.

Intermediate 3.4.1 Demonstrate the ability to work with others, present facts that support arguments, listen to dissenting points of view, and reach a shared decision. √

Commencement 3.4.1 Communicate effectively and help others to learn a new skill. √

- Technology

Technology is the process and product of human skill and ingenuity in designing and creating things from available resources to satisfy personal and societal needs and wants.

Elementary 3.5.1 Demonstrate an awareness of the different types of technology available to them and of how technology affects society.

Intermediate 3.5.1 Select and use appropriate technology to complete a task. √

Commencement 3.5.1 Apply their knowledge of technology to identify and solve problems. √

- Managing Information

Information management focuses on the ability to access and use information obtained from other people, community resources, and computer networks.Elementary 3.6.1 Describe the need for data and obtain data to make decisions. √

Intermediate 3.6.1 Select and communicate information in an appropriate format (e.g., oral, written, graphic, pictorial, multimedia). √

Commencement 3.6.1 Use technology to acquire, organize, and communicate information by entering, modifying, retrieving, and storing data. √

- Managing Resources

Using resources includes the application of financial and human factors, and the elements of time and materials to successfully carry out a planned activity.Elementary 3.7.1 Demonstrate an awareness of the knowledge, skills, abilities, and resources needed to complete a task. √

Intermediate 3.7.1 Understand the material, human, and financial resources needed to accomplish tasks and activities. √

Commencement 3.7.1 Allocate resources to complete a task. √

- Systems

Systems skills include the understanding of and ability to work within natural and constructed systems.Elementary 3.8.1 Demonstrate understanding of how a system operates and identify where to obtain information and resources within the system. √

Intermediate 3.8.1 Understand the process of evaluating and modifying systems within an organization. √

Commencement 3.8.1 Demonstrate an understanding of how systems performance relates to the goals, resources, and functions of an organization. √

- Basic skills

Career Development and Occupational Studies

Standards-based education addresses three types of standards

- content—identify what students should know and be able to do

- performance—identify levels of achievement in relation to the content standards, answering the question "How good is good enough?"

- opportunity-to-learn—the availability of resources, programs, and qualified teachers needed to enable the students to meet the identified standards.

Meeting CDOS Standards means:

- Learning experiences have real-life applications.

- Lessons are authentic and project-based.

- Lessons are experiential in nature.

- Lessons are hands-on.

- Lessons connect to careers.

- Students are able to connect present learning to future goals.

- Students explore various career paths without limiting their choices.

- Students engage in career role-playing.

- Students learn and then apply skills they learn in school.

- Students participate in entrepreneurial endeavors in the school environment.

- Students integrate knowledge with experience.

- Students offer comments of how much they are looking forward to their future careers because classroom activities are relevant to the real world.

- The teacher discusses his/her own skills with students.

- Assessment directly measures performance.

-

Standard 2:details

Integrated Learning

Students will demonstrate how academic knowledge and skills are applied in the workplace and other settings.

Integrated learning encourages students to use essential academic concepts, facts, and procedures in applications related to life skills and the world of work. This approach allows students to see the usefulness of the concepts that they are being asked to learn and to understand their potential application in the world of work.

Elementary 2.1 Identify academic knowledge and skills that are required in specific occupations 2.2 Demonstrate the difference between the knowledge of a skill and the ability to use the skill 2.3 Solve problems that call for applying academic knowledge and skills. √

Intermediate 2.1 Apply academic knowledge and skills using an interdisciplinary approach to demonstrate the relevance of how these skills are applied in work-related situations in local, state, national, and international communities 2.2 Solve problems that call for applying academic knowledge and skills √ 2.3 Use academic knowledge and skills in an occupational context, and demonstrate the application of these skills by using a variety of communication techniques (e.g., sign language, pictures, videos, reports, and technology).

Commencement 2.1 Demonstrate the integration and application of academic and occupational skills in their school learning, work, and personal lives. √ 2.2 Use academic knowledge and skills in an occupational context, and demonstrate the application of these skills by using a variety of communication techniques (e.g., sign language, pictures, videos, reports, and technology) √ 2.3 Research, interpret, analyze, and evaluate information and experiences as related to academic knowledge and technical skills when completing a career plan. - Standard 3a: details

Universal Foundation Skills Students will demonstrate mastery of the foundation skills and competencies essential for success in the workplace.

- Basic skills

Basic skills include the ability to read, write, listen, and speak as well as perform arithmetical and mathematical functions.

Elementary 3.1.1 Listen to and read the ideas of others and express themselves both orally and in writing; they use basic mathematical concepts and computations to solve problems. √

Intermediate 3.1.1 Listen to and read the ideas of others and analyze what they hear and read; acquire and use information from a variety of sources; and apply a combination of mathematical operations to solve problems in oral or written form. √

Commencement 3.1.1 Use a combination of techniques to read or listen to complex information and analyze what they hear or read; convey information confidently and coherently in written or oral form; and analyze and solve mathematical problems requiring use of multiple computational skills. √ - Thinking skills

Thinking skills lead to problem solving, experimenting, and focused observation and allow the application of knowledge to new and unfamiliar situations.

Elementary 3.2.1 Use ideas and information to make decisions and solve problems related to accomplishing a task. √

Intermediate 3.2.1 Evaluate facts, solve advanced problems, and make decisions by applying logic and reasoning skills. √

Commencement 3.2.1 Demonstrate the ability to organize and process information and apply skills in new ways. √

- Personal Qualities

Personal qualities generally include competence in self-management and the ability to plan, organize, and take independent action.

Elementary 3.3.1 Demonstrate the personal qualities that lead to responsible behavior. √

Intermediate 3.3.1 Demonstrate the ability to work with others, present facts that support arguments, listen to dissenting points of view, and reach a shared decision. √

Commencement 3.3.1 Demonstrate leadership skills in setting goals, monitoring progress, and improving their performance. √

- Interpersonal Skills

Positive interpersonal qualities lead to teamwork and cooperation in large and small groups in family, social, and work situations.

Elementary 3.4.1 Relate to people of different ages and from diverse backgrounds.

Intermediate 3.4.1 Demonstrate the ability to work with others, present facts that support arguments, listen to dissenting points of view, and reach a shared decision. √

Commencement 3.4.1 Communicate effectively and help others to learn a new skill. √

- Technology

Technology is the process and product of human skill and ingenuity in designing and creating things from available resources to satisfy personal and societal needs and wants.

Elementary 3.5.1 Demonstrate an awareness of the different types of technology available to them and of how technology affects society.

Intermediate 3.5.1 Select and use appropriate technology to complete a task. √

Commencement 3.5.1 Apply their knowledge of technology to identify and solve problems. √

- Managing Information

Information management focuses on the ability to access and use information obtained from other people, community resources, and computer networks.Elementary 3.6.1 Describe the need for data and obtain data to make decisions. √

Intermediate 3.6.1 Select and communicate information in an appropriate format (e.g., oral, written, graphic, pictorial, multimedia). √

Commencement 3.6.1 Use technology to acquire, organize, and communicate information by entering, modifying, retrieving, and storing data. √

- Managing Resources

Using resources includes the application of financial and human factors, and the elements of time and materials to successfully carry out a planned activity.Elementary 3.7.1 Demonstrate an awareness of the knowledge, skills, abilities, and resources needed to complete a task. √

Intermediate 3.7.1 Understand the material, human, and financial resources needed to accomplish tasks and activities. √

Commencement 3.7.1 Allocate resources to complete a task. √

- Systems

Systems skills include the understanding of and ability to work within natural and constructed systems.Elementary 3.8.1 Demonstrate understanding of how a system operates and identify where to obtain information and resources within the system. √

Intermediate 3.8.1 Understand the process of evaluating and modifying systems within an organization. √

Commencement 3.8.1 Demonstrate an understanding of how systems performance relates to the goals, resources, and functions of an organization. √

- Basic skills

- Standard 3b: details

Career Majors Students who choose a career major will acquire the career-specific technical knowledge/skills necessary to progress toward gainful employment, career advancement, and success in postsecondary programs.- Business/Information Systems

Core 3b.1 Basic Business Understanding—demonstrate an understanding of business, marketing, and multinational economic concepts, perform business-related mathematical computations, and analyze/interpret business-related numerical information. 3b.2 Business-Related Technology—select, apply, and troubleshoot hardware and software used in the processing of business transactions. 3b.3 Information Management/Communication—prepare, maintain, interpret/analyze, and transmit/ distribute information in a variety of formats while demonstrating the oral, nonverbal, and written communication skills essential for working in today's international service-/information-/technological-based economy. 3b.4 Business Systems—demonstrate an understanding of the interrelatedness of business, social, and economic systems/subsystems.

Specialized 3b.5 Resource Management—identify, organize, plan, and allocate resources (e.g., financial, materials/facilities, human, time) in demonstrating the ability to manage their lives as learners, contributing family members, globally competitive workers, and self-sufficient individuals.

Experiential 3b.1 Basic Business Understanding—demonstrate an understanding of business, marketing, and multinational economic concepts, perform business-related mathematical computations, and analyze/interpret business-related numerical information. 3b.2 Business-Related Technology—select, apply, and troubleshoot hardware and software used in the processing of business transactions. 3b.3 Information Management/Communication—prepare, maintain, interpret/analyze, and transmit/ distribute information in a variety of formats while demonstrating the oral, nonverbal, and written communication skills essential for working in today's international service-/information-/technological-based economy. 3b.4 Business Systems—demonstrate an understanding of the interrelatedness of business, social, and economic systems/subsystems. 3b.5 Resource Management—identify, organize, plan, and allocate resources (e.g., financial, materials/facilities, human, time) in demonstrating the ability to manage their lives as learners, contributing family members, globally competitive workers, and self-sufficient individuals. 3b.6 Interpersonal Dynamics—exhibit interpersonal skills essential for success in the multinational business world, demonstrate basic leader- ship abilities/skills, and function effectively as members of a work group or team. - Engineering/Technologies

Core, Specialized and Experiential 3b.1 Foundation Development—Develop practical understanding of engineering technology through reading, writing, sample problem solving, and employment experiences. 3b.2 Technology—Demonstrate how all types of engineering/technical organizations, equipment (hardware/software), and well-trained human resources assist and expedite the production/distribution of goods and services 3b.3 Engineering/Industrial Processes—Demonstrate knowledge of planning, product development and utilization, and evaluation that meets the needs of industry.

- Business/Information Systems

Essential Questions

details| Who am I as a citizen? | Students develop self-management skills for researching a topic. Students develop critical thinking skills. Students develop effective interpersonal skills. | |

| How are my school experiences connected to my future success? | Students will acquire skills in decision making, communication, and teamwork. Students will learn various management skills. Students will participate in a simulated work environment. | |

| How are my social skills related to my future success? | Students will predict future situations. Students will work as a team to complete a project. Students will develop problem-solving strategies. Students will interact effectively with team partners. | |

| How do I develop the skills and abilities that I need to be successful in a career? How do I find out what I want to know? | Students will research topics using the internet | |

| Why do the choices I make now matter to my future? | Students will gain an awareness of the importance of personal responsibility and good work habits. Students will gain an awareness of the impact of their actions and choices. | |

| How do I affect the systems within which I live and work? |

| Business/Information Systems (3b) | |

| Basic Business Understanding | |

| Business-Related Technology | |

| Information Management/ Communication | |

| Business Systems | |

| Resource Management | |

| Interpersonal Dynamics | |

| Career Development (1) | |

| Complete development of career plan | |

| Apply decision-making skills in selection of a career option | |

| Analyze skills and abilities in a career option | |

| Integrated Learning (2) | |

| Demonstrate integration and application | |

| Use academic knowledge and skills | |

| Research, interpret, analyze, and evaluate information | |

| Universal Foundation Skills (3a) | |

| Basic Skills | |

| Thinking Skills | |

| Personal Qualities | |

| Interpersonal Skills | |

| Technology | |

| Managing Information | |

| Managing Resources | |

| Systems | |

Extruding

TinkerCad

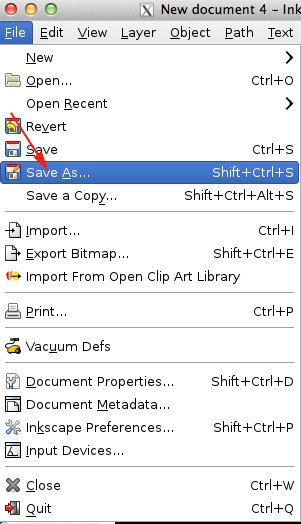

- If you don't have Inkscape, download and install it from here. Otherwise open the application.

- Create a New Document. CTRL+N

- Use the available tools to create your image.

- Save the Drawing as an SVG

- Open a webGL enabled browser like Google Chrome or Firefox

- Navigate to tinkercad.com

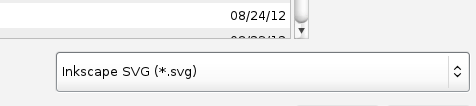

- Once you have signed in or created a new account, click the button to design a new thing:

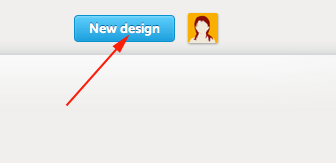

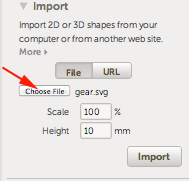

- Instead of dragging a shape on to the work plane, toggle open the import menu:

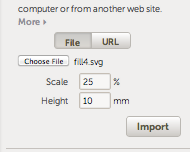

- Select File press Choose File, set the scale and height and then click on the Import button:

Blender

Blender provides a very simple way to extrude SVG files. This is great for whenever you want to convert 2D to 3D.- If you don't have Inkscape, download and install it from here. Otherwise open the application.

- Create a New Document. CTRL+N

- Use the available tools to create your image.

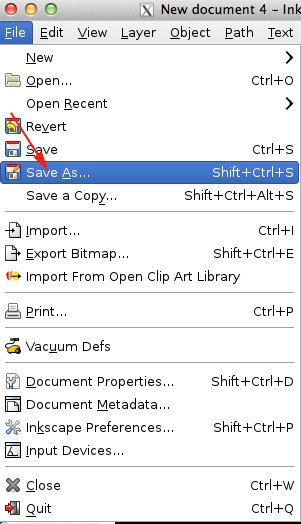

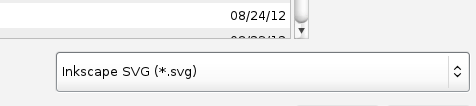

- Save the Drawing as an SVG

- If you don't have Blender installed, download it from blender.org and install it.

- Open Blender

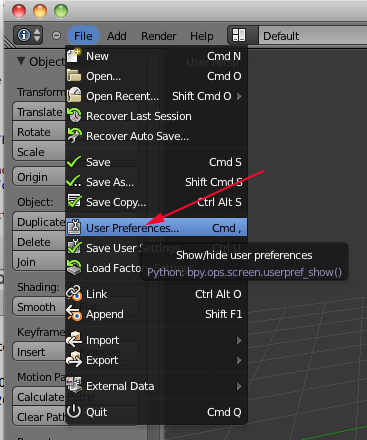

- If you have never used Blender before navigate to File>User Preferences or type (CMD+,).

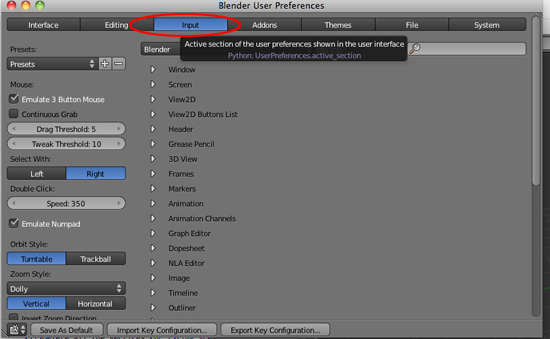

- Click on Input

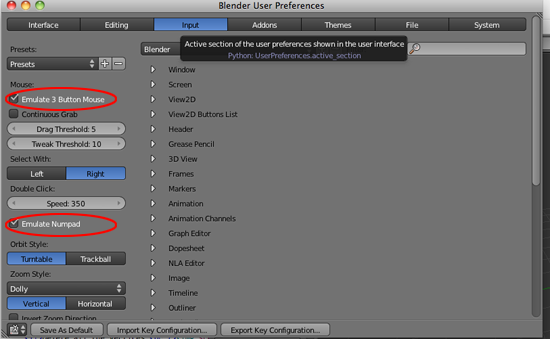

- Click on Emulate Button Mouse and Emulate Numpad

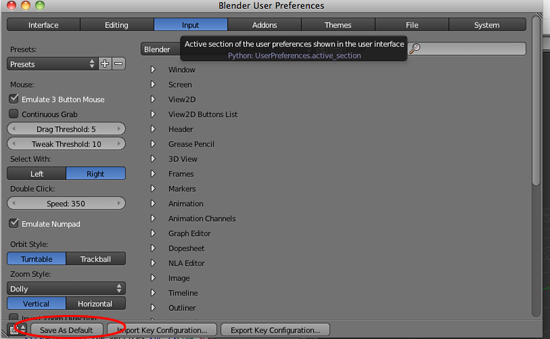

- Click on Save As Default

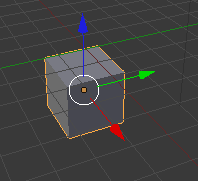

- If the cube is not selected (if there is not an orange line around it), RIGHT click on it to select it:

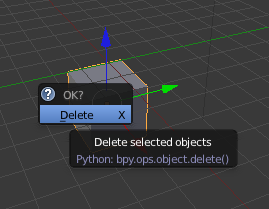

- Press X and click on Delete to delete the cube.

- Click on File>Import>Scalable Vector Graphic (.svg) and navigate to your .svg file and click on Import .SVG button in the top right corner.

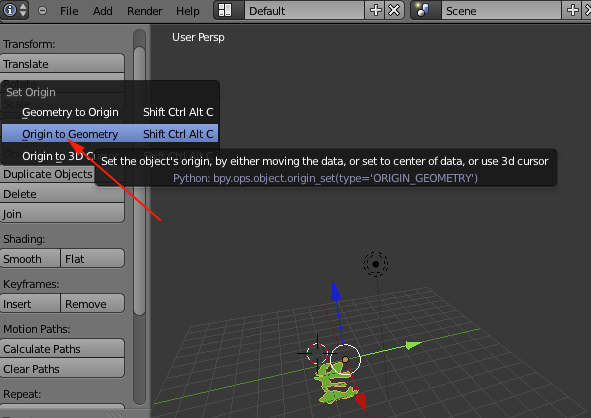

- RIGHT+click on the imported file so that it is selected.

- In the left panel select Origin to Geometry

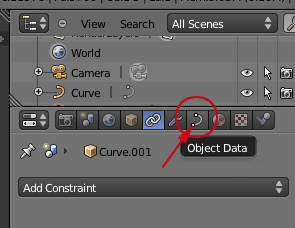

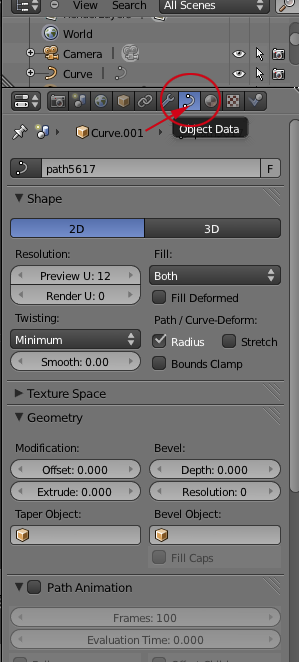

- Click on Object Data in the Right Panel:

- This will open the Object Data panel:

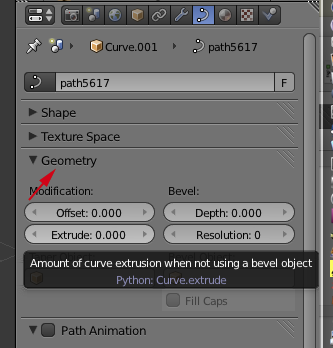

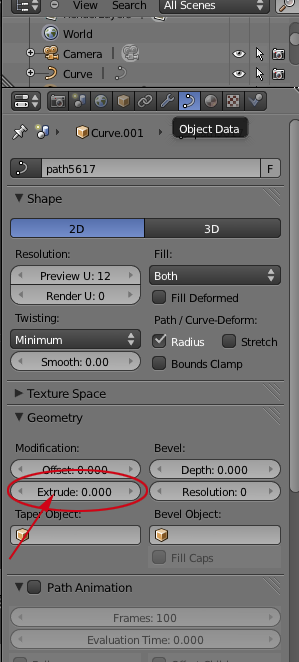

- If it isn't open, toggle open the Geometry panel

- CTRL+click on Extrude

- Change the extrude value to 1

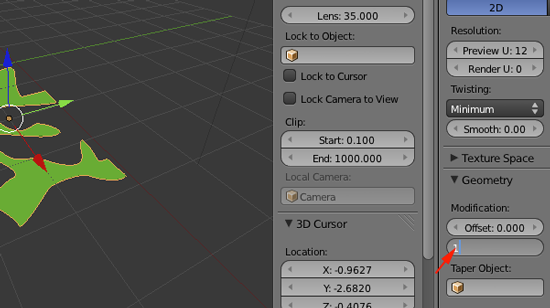

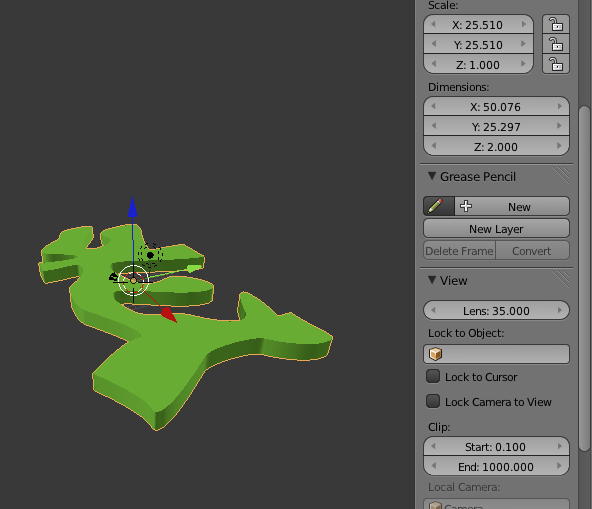

- In the Viewport press N. And resize your shape by pressing S and scaling up so that your width matches your your width from the original .svg file:

- Set the z to however high you want your tile.

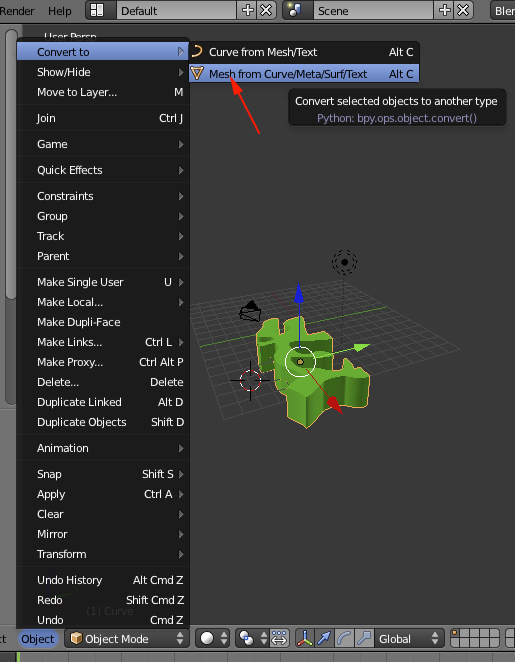

- Convert the shape to a mesh by selecting Object>Convert To>Mesh from Curve

- Select the object if it is not selected and select File>Export>STL(.stl)

OmNomNom Creator

OmNomNom Creator is an application for the Mac that allows you to automatically generate 2D drawings into 3D objects. The application was created by Thingiverse user Jetty.To use the application, just drag and drop any common image format (gif, jpg, png, tiff etc.) into OmNomNom and choose the output format you want, and it will export an STL file for 3D printing. It requires OpenSCAD 2011.12 or later version to be installed.

You can use OmNomNom Creator to create 3D Cookie Cutters, Medallions, Logos, Surface Maps, Mazes, QR Codes, Stamps, or for anything where you need to get a 2D image into a 3D project.

/*assignment part 2*/