Pulleys

Pulleys work in a similar way to gears, except they are not directly joined but linked by a belt. Belts can be elastic bands, tubular springs or some other flexible but strong material. A common example of a belt is the fan belt in a car that links a number of pulleys together. To stop the pulley belt slipping off, pulleys often have grooved rims. The grooved ring also keeps the belt running in a straight line. Pulleys that use some form of belt drive are referred to as Friction Drive mechanisms. A drive mechanism such as gears which physically make contact, is referred to as Positive Drive.

Pulleys have several advantages over gears, but they also have some disadvantages. The main advantage is that they are simple to make and can be used at a distance from each other, unlike gears that need to touch in order to work. The disadvantage is that they work by friction and so can slip.

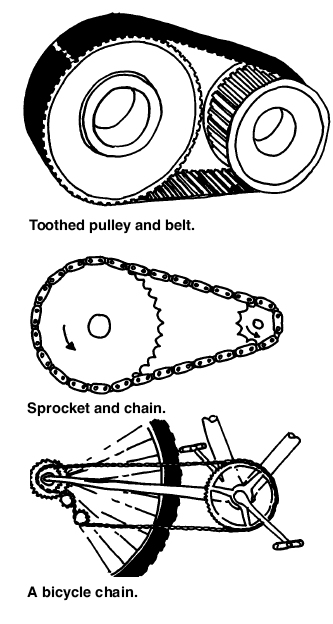

A toothed pulley and belt eliminates any slipping or timing problems. Many cars have a cam belt that works on this principle.

The belt can also be substituted by a chain. A bicycle is a great example of this system. Model suppliers often stock small plastic toothed pulleys or chain sets which are reasonably priced.

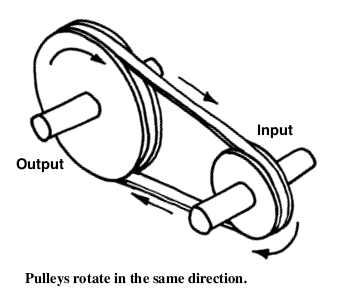

By dividing the input diameter by that of the output, you can workout a final ratio. A ratio of 2:1 means for every two revolutions of the input pulley the output turns one full revolution. You can also reverse the input and output pulleys.

You can see that pulleys rotate in the same direction (unlike gears which do the opposite).

Pulleys are useful for getting the drive action to happen in awkward places. You can use the drive pulley to transmit its motion to the output pulley which may be some distance away.

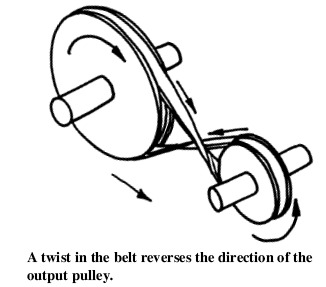

You can also use pulleys to reverse the action by putting a twist into the belt. This makes the output pulley move in the opposite direction.

Constructing Pulleys

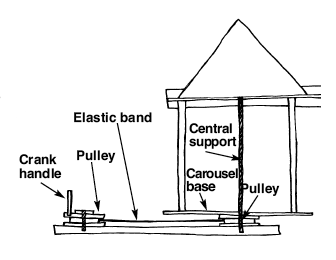

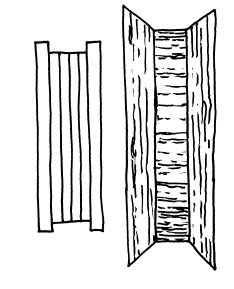

Laminating is one of the easiest ways to make a pulley wheel. Use several circles of card making two of them slightly bigger (around 5mm). Glue them together, sandwiching the smaller ones in the middle. Make sure that the pulley is a little wider than your belt, and try to keep the centers lined up. When the glue has set you can drill the center out to the size of the drive shaft.

Fitting the elastic band is often the final part of the assembly process before gluing everything. Finally, make sure everything is strong enough to take the tension of the pulley. Remember you are dealing with a friction drive, so the tighter the belt the less chance you have of it slipping. Make sure that any axles are strong enough to take the load. For more information see Printeraction's Instructable on Basic Pulley Mechanisms