Why are we here?

As educators we need to prepare students for the future:

'shift' refers to preparing students for the next (rather than the last) half century.

What is 3D Printing?

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The process of designing, inventing and fabricating exposes those new involved in 3D printing to industries such as industrial design, engineering and material science.

3D printing involves:

- Computer Aided Design and Drafting (CADD)

- Rapid Prototyping (RP)

- Reverse Engineering

- Brainstorming and ideation

- Development of workflows

We're here to determine how to incorporatate 3D printing into our classes

Whether you teach k12, higher ed, or work in an informal learning environment, integrating 3D Printing into your teaching practice will help you meet the following objectives:- Encourage students to be more responsible for their own learning outcomes, or put another way, support personal student exploration in the pursuit of a learning objective.

- Provide powerful learning aids, like Design Thinking techniques.

- Build cooperative learning opportunities.

- Build resiliency by taking advantage of rapid prototyping and testing techniques.

- Develop communication skills through continuous documentation and sharing.

More reasons why you should incorporate 3D technology into education:

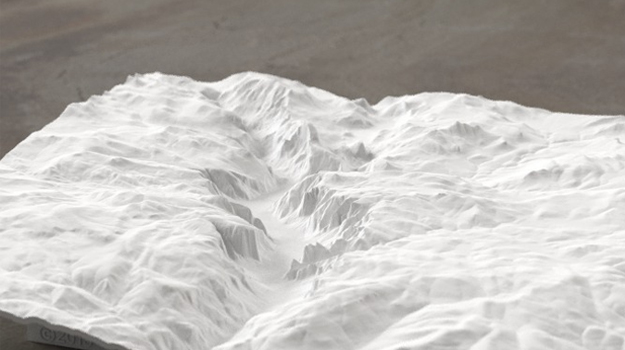

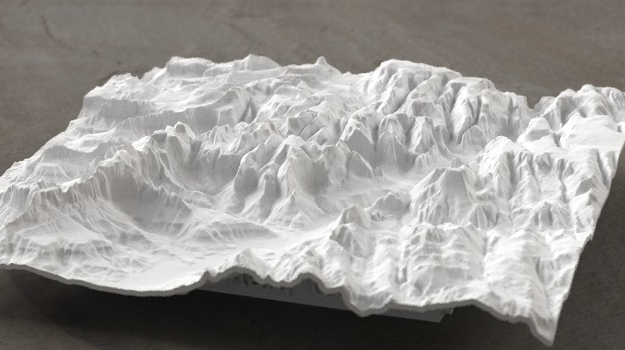

- It can help visualize data.

- It can provide tactile feedback.

- It encourages you to quickly prototype.

- It invites you into the realm of the D.I.Y. ethic.

- It engages you in STEM-based projects.

- It serves as another means of communication.

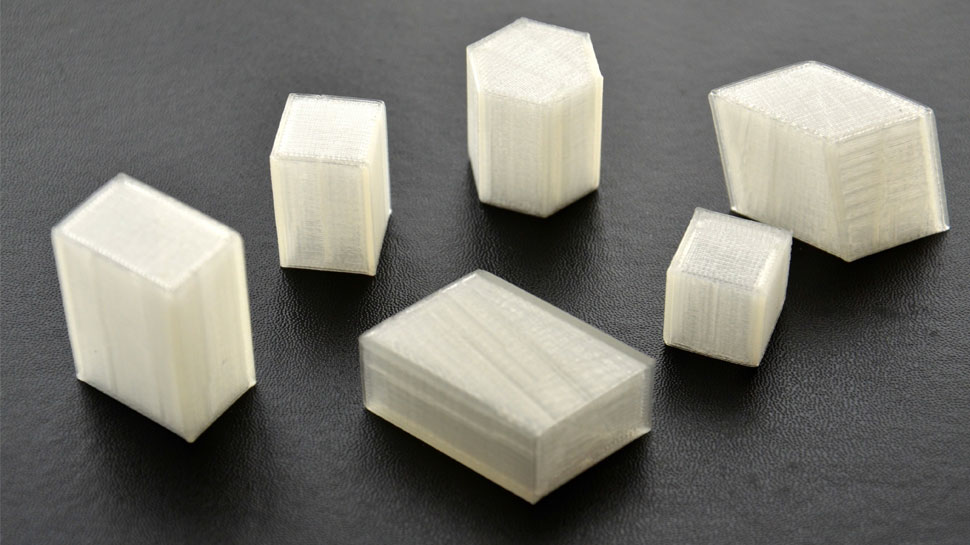

What can be printed?

3DX Fashion

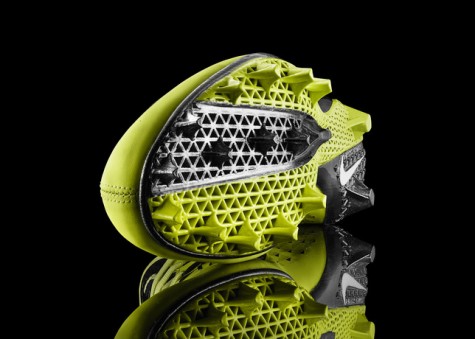

Footwear and apparel company Nike believes 3D printing technology can speed up athletic performance

Image from

inBloom Dress by XYZ Workshop Aug 19, 2014

Instructable

3DX Food

Loris Tupin, a French industrial designer from Maxilly sur Léman, presented the biodynamic model of a flower that, from a bud, changes into a rose during cooking

Image from 3dprintingindustry.com

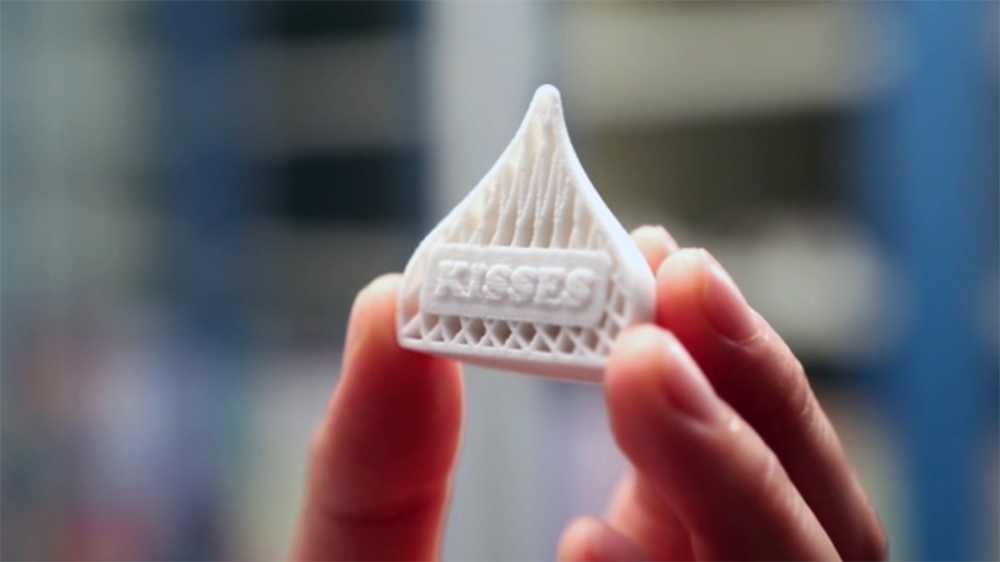

Hershey Unveils 3-D Chocolate Candy Printing Exhibit in Partnership with 3D Systems

Image from 3dprintingindustry.com

Ingredients are loaded into stainless steel capsules. Load them with beef to print out mini burgers.

Image from cnn.com

More Links

- Luis Rodriguez

- All3DP

- Restaurants using 3D printers:

- Pinshape: 5 Step Beginners Guide to 3D Printing Food

- 3D printing dessert: Liz and Kyle von Hasseln

3DX Health and Medicine

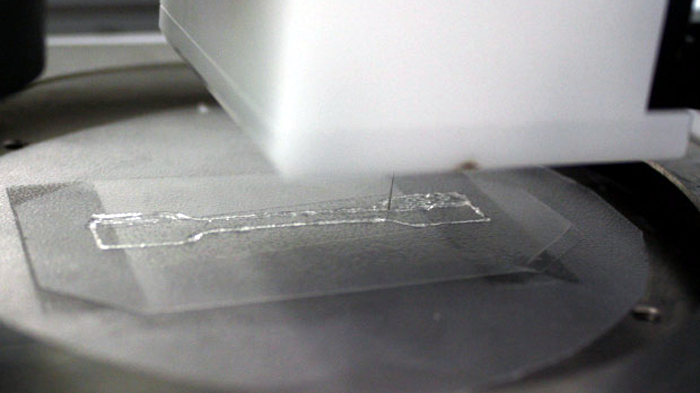

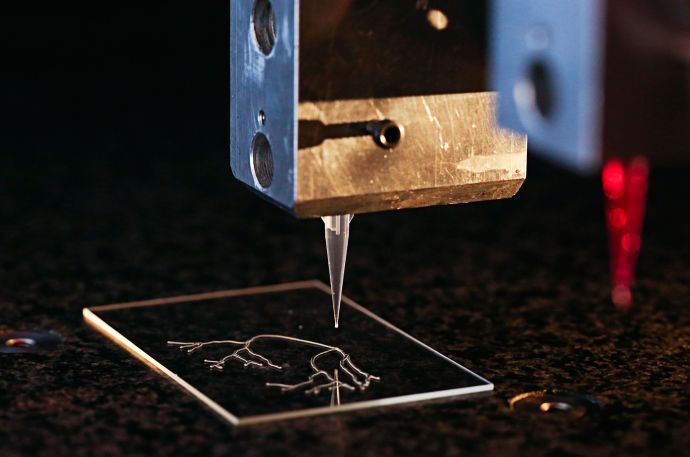

A 3-D printer used by researchers at Harvard University's Wyss Institute creates a model vascular network.

Image from LORI K. SANDERS

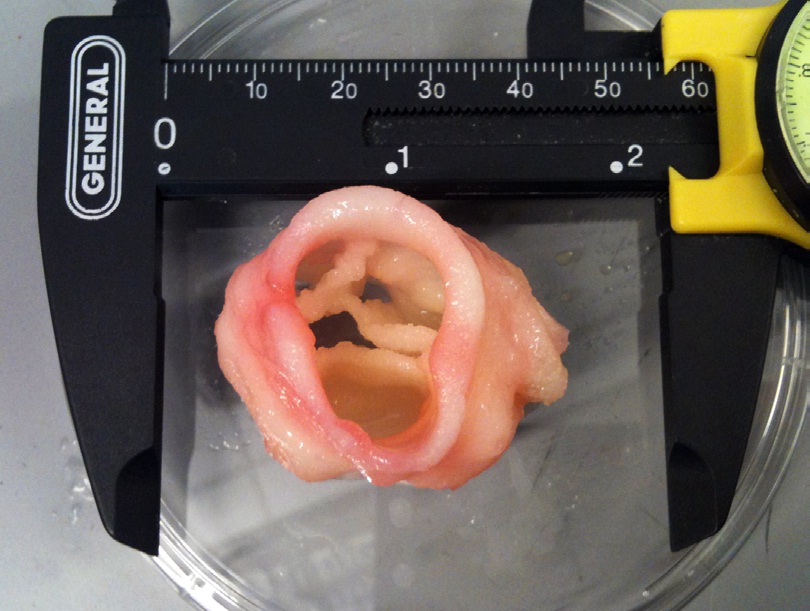

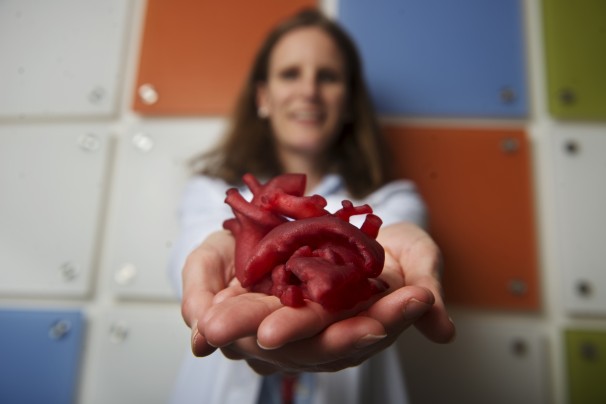

Pediatric cardiologist Laura Olivieri of Children's National Medical Center displays a heart model created by a 3-D printer. (Amanda Voisard/For The Washington Post)

Image from Washington Post

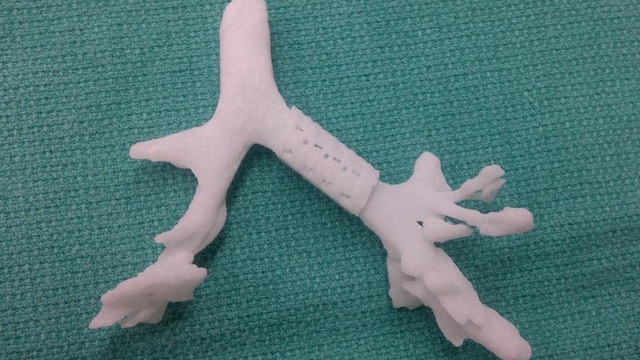

Bioresorbable Airway Splint Created with a Three-Dimensional Printer

Image from The New England Journal of Medicine

Image from dezeenYoung girls that suffer from spinal curvature will soon be able to wear lighter and more stylish 3D-printed braces to treat their condition.

3DX Data Visualization

Cylinder by Andy Huntington and Drew Allan may be one of the first digitally-fabricated sound sculptures. Also see our entry 2007 – Explosion of sound sculptures.

Images from extraversion

Weather data is another interesting choice for creating data jewelry. Above to the left is a bracelet created by Mitchell Whitelaw based on one year of weather data from Canberra. The right image shows a measuring cup made by the same artist, where each ring represents monthly average temperatures in Sydney over 150 years. Sources: Mitchell Whitelaw. Weather Bracelet (2009) Mitchell Whitelaw. Measuring Cup (2010)

Images from teemingvoid

A 3D bar chart on top of a keyboard which shows the frequency of each letter in the alphabet. Source: Michael Knuepfel. Keyboard Frequency Sculpture.

Images from portfolio.spike5000

2013 – NYC High School Dropouts

Ben Kauffman and Sam Brenner created this visualization as part of the ITP program at the NYU Tisch School of the Arts. It is a combination of a 3D-printed relief map of New York City with beads where each bead represents one school location. Each bead on top of the relief map is connected to a string below whose length indicates the number of students who dropped out of that school.

Images from benkauffman

Sound Bites is the result of an experimental design practice. Four days of 24/7 ambient sound recordings resulted in 128 4-second intimate sound loops. Fast Fourier Transform frequency analysis and geometrical operations transformed time, frequency, and amplitude into X, Y and Z dimensions, forming 3D sonic shapes. These 'disco donuts' were 3D printed into 128 sound objects. Vacuum molded they formed the base to cast 128 unique chocolate objects. New rhythmic patterns were created, comprising frozen moments in time.

Matter is energy. Objects are processes. Memories are expectations.

Images from soundbitessoundbites

Visual journalist Jon Keegan created this quick chart using U.S. unemployment rate starting from January 1948 (the first year that the U.S. started to record the number) through the end October 2015. The long axis represents years from 1948-2015, and each column is made of of 12 chips, each representing one month's unemployment rate figure. The height of each chip represents the rate for that month. One can see a dramatic cliff start to rise up in the fall of 2008, as the global economic downturn began to unfold. Equally interesting is the slow, but steady recovery as unemployment drops through the end of 2015. Source: U.S. Bureau of Labor Statistics.

Inspired by the fantastic 2D heat map from WSJ (where Jon used to work).

Source data and OpenSCAD files.

Images from U.S. Unemployment Rate 1948-2015 (monthly)

This is a cool little app. Known as The Vibe, it's an iPhone case you can customize to your favorite sound using SoundCloud.

Images from makepartsfast.com

French, digital artist, Gilles Azzaro, explores a Barack Obama State of the Union Address, by turning peaks in soundwaves into shining plastic.

Images from creators.vice.com

3DX Design

Henry Segerman and Saul Schleimer cast astounding shadows and designs from their designs.

Image from 3dprintingindustry.com

3DX Art

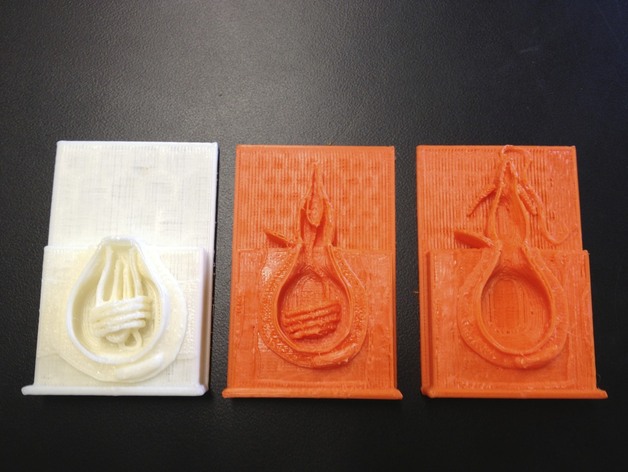

Rodin Remix is a hands-on space that encourages visitors to explore and create figures based on the artists' own process of reusing old fragments in new works. It also puts a modern spin on Rodin's method of mass production by showcasing pieces printed on 3D printers.

Image from Portland Museum

Design lecturer John Edmark has created a series of designs for 3D-printed sculptures that appear to move, utilising an effect similar to a zoetrope

Image from Dezeen

Argentinian artist Adri�n Villar Rojas has transformed the Cantor Roof with an intricate site-specific installation that uses the Museum itself as its raw material. Featuring detailed replicas of nearly 100 objects from The Met collection, The Theater of Disappearance encompasses thousands of years of artistic production over several continents and cultures, and fuses them with facsimiles of contemporary human figures as well as furniture, animals, cutlery, and food. Each object—whether a 1,000-year-old decorative plate or a human hand—is rendered in the same black or white material and coated in a thin layer of dust.

Image from NYT

For a national campaign of the World Animal Protection, Joris created a 3D print installation with 5 Ultimakers combined with Z-Unlimited add-on. With this installation he was able to print a life size elephant live at Schiphol airport within 2 weeks time. The elephant served as a 3D petition against elephant abuse in the tourist industry: Only when people signed the petition the printers were actively printing the elephant. All 30.000 names of the people that signed the petition are engraved in the 3D printed elephant skin.

Image from Joris Rooie

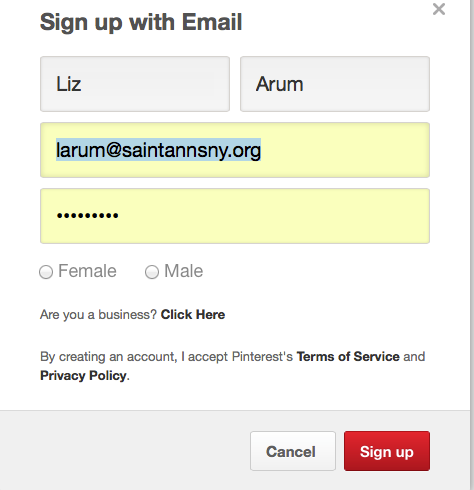

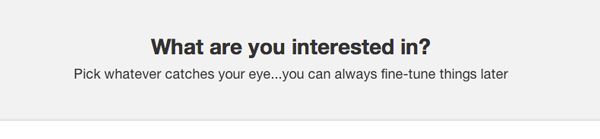

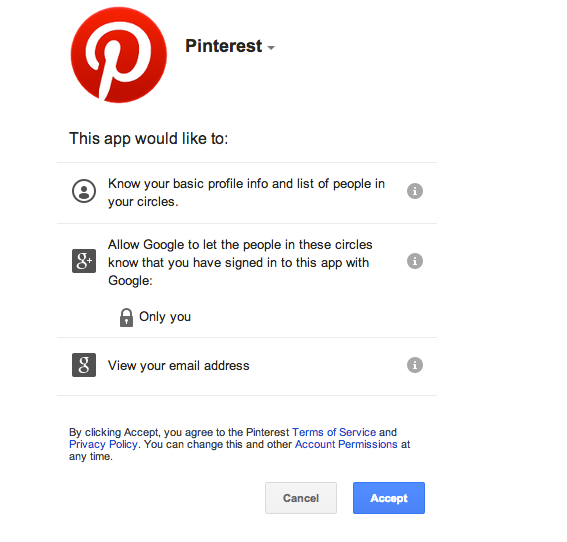

Pinterest is a visual discovery tool to help you find ideas and inspiration. You can have secret boards that you share with a group.

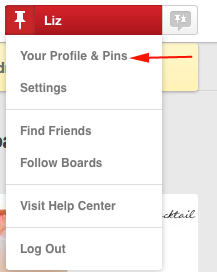

- Navigate to Pinterest

- Create an account

- Skip this step twice:

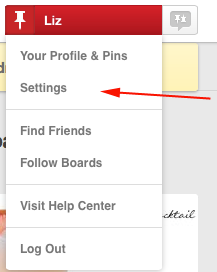

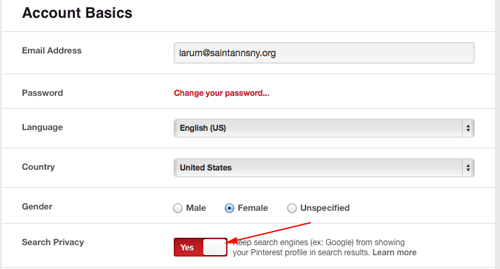

- Click on Settings

- Change Privacy Setting

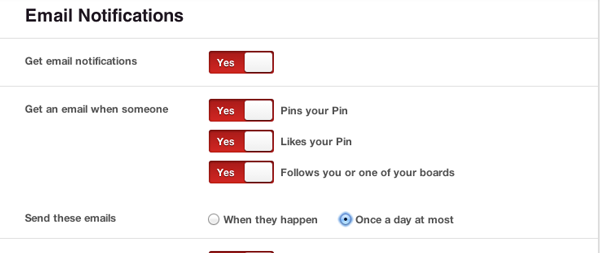

- Change Email Notifications:

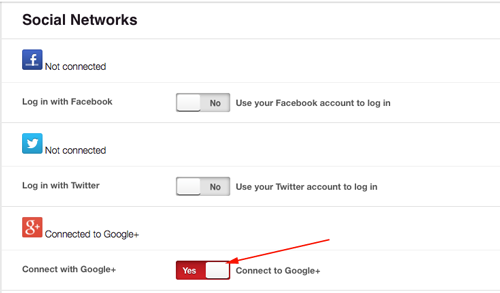

- Select to connect with Google+

- Accept Google prompt

- Log Out and navigate to email account. Click the link and return to Pinterest

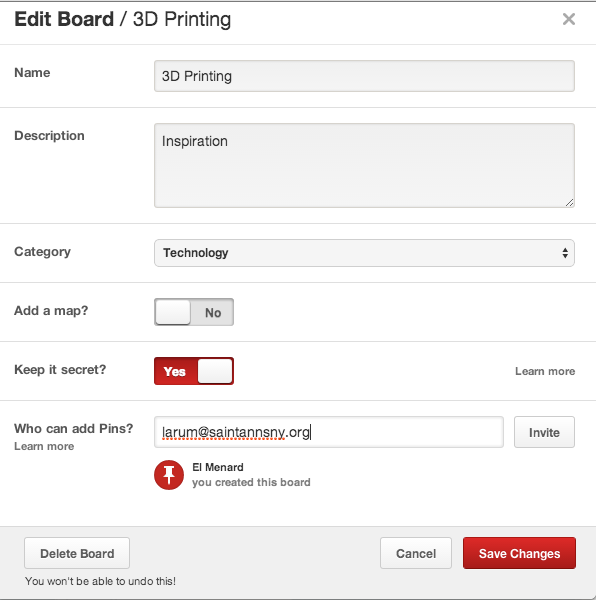

- Create a board

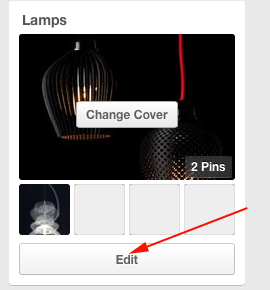

- To see your boards click here

- Click the Edit button

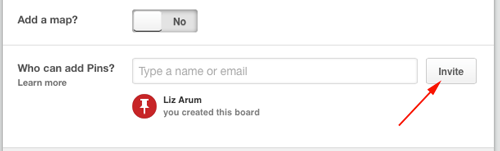

- Don't forget to Invite me to your board

- If using Google Chrome to browse Navigate to webstore and install the Pin it Button

- If browsing with Safari

- Go to Goodies page from Safari

- Click Install Now

- After installing, you'll see a Pin It button any time you mouse over an image. Or, click the P at the top of your browser whenever you find something on the web you want to Pin.

- If you find yourself distracted by the hovering Pin It buttons, you can turn them off:

- From Safari, go to Preferences then Extensions

- Click Hide hovering Pin It buttons

Repositories

| Site name | Description | Company | Page views per day | Unique visitors per day |

|---|---|---|---|---|

| Trimble 3D Warehouse | 3D models for SketchUp | Trimble | 969,680( 4.96 per visitor) | 195,500 |

| Thingiverse | Launched in 2008, Thingiverse continues to support a thriving community for making and sharing 3D printable things | MakerBot | 1,924,510 (14.47 per visitor) | 133,000 |

| TurboSquid | Stock 3D models | TurboSquid | 267,375 (4.65 per visitor) | 57500 |

| CG Trader | Primarily a place to buy and sell 3D models of all kinds | CGTrader | 160,704 (3.72 per visitor) | 43,200 |

| Yeggi | Search engine | Yeggi | 91,520 (4.16 per visitor) | 22,000 |

| MyMiniFactory | A site of curated downloadable 3D objects. Each object on the site is guaranteed to be printable | iMakr | 149,160 (9.04 per visitor) | 16500 |

| Sketchfab | Site for displaying and sharing 3D content online. Strong in scanned art | SketchFab | 40,221 (2.81 per visitor) | 14314 |

| Pinshape | Site offers both 'premium'(paid) STL files and free STL files for 3D printing | FormLabs | 32,918 (3.02 per visitor) | 10,900 |

| Yobi3D | Search engine | Yobi3D Inc | 20,265 (2.10 per visitor) | 9,650 |

| 3D Content Central | A free service for locating, configuring, downloading, and requesting 2D and 3D parts and assemblies, 2D blocks, library features, and macros | Dassault Systèmes | 11,949 (3.00 per visitor) | 3983 |

| STL Finder | Search engine | Miguel Angel Villar Alarcon | 14,040 (5.20 per visitor) | 2700 |

| Artec 3D Scans | Site of high resolution 3D scan models made using Artec Eva, Spider and Space Spider handheld 3D scanners and Artec Studio scanning and processing | Artec Europe | 3,240 (2.20 per visitor) | 1473 |

| Cults 3D | 3D printing marketplaces that offers both paid and free high quality STL files for 3D printing | Cults | 6,615 (4.90 per visitor) | 1350 |

| YouMagine | A 3D content repository managed by Ultimaker that features free STL files for 3D printing. YouMagine is commited to protecting their 3D designers | Ultimaker | 6,633 (8.10 per visitor) | 819 |

| 3DShook | Subscription service for catalog of 3D models designed by skilled product and industrial designers | 3DShook LTD | 2,325 (3.10 per visitor) | 750 |

| GrabCAD | 3D printing community by mechanical engineers, for mechanical engineers | Stratasys | 2,436 (3.70 per visitor) | 658 |

| RascomRas | Spanish Language repository | RascomRas | 3,415 (5.30 per visitor) | 644 |

| Threeding | A marketplace for free and paid 3D printable models and files | Threeding.com | 1,500 (3.00 per visitor) | 500 |

| Repables | Simple website that allows users to upload their files to share, and download files they want to use | Repables | 1,001 (2.90 per visitor) | 345 |

| 3dkitbash | Toys, Skulls, and 3D Printer Test Kits | Ghost Capital, LLC | 899 (2.90 per visitor) | 310 |

| Redpah | Repository specifically designed for printable 3D models | Redpah | 452 (2.10 per visitor) | 215 |

| Digital Morphology Library | This collection of 3D models of fossils is generated at the National Science Foundation's multi-user CT lab | UTCT/DigiMorph.org | 630 (3.00 per visitor) | 210 |

| Libre 3D | Online 3D model repository | 3dhacker llc | 434 (2.30 per visitor) | 189 |

| The Forge | Free 3D-printable models designed by Zheng3 | Zheng3 | 315 (2.10 per visitor) | 150 |

| ShapeKing | Shapeking community provides 3D printing interested and advanced people a platform for the exchange of information and 3D models | shapeking.com | 263 (2.50 per visitor) | 105 |

| 3DAGOGO | Site allows users to buy and sell 3D models, while also offering a large selection of completely free STL files for 3D printing, all tested for prinatability | 3DAGOGO | 240 (2.90 per visitor) | 83 |

| 3D File Market | Open market place for designers where all 3d print files are proven printable and verified. Both free and paid downloads available. | 3DFileMarket.com | 240 (3.00 per visitor) | 80 |

| STLHive | 3D print models for radio-controlled cars, drones, and robotics | STLHive | 46 (2.30 per visitor) | 80 |

| African Fossils | African Fossils seeks to increase public knowledge about prehistory by harnessing modern technology. Through digitizing otherwise inaccessible discoveries, the organization is dedicated to creating a growing repository of 3D models of significant fossils and artifacts, thus making them freely accessible to all | African Fossils | 169 (2.60 per visitor) | 65 |

| GB3D Type Fossils | The UK repository for digitized type fossil specimens | British Geological Survey and JISC GB3D Type Fossils Online project partners | 84 (2.10 per visitor) | 40 |

| Trinpy | Royalty-Based 3D Printing Repository | Trinpy PTY LTD | 120 (4.00 per visitor) | 30 |

| LibraryLyna | 3D math and science models for the visually impaired and everyone else | LIBRARYLYNA | 75 (5.00 per visitor) | 15 |

| X 3D Smithsonian | 3D print ready model created from laser scan data | Smithsonian | NA | NA |

| Audilab | Models of the human ear | McGill | NA | NA |

| McMaster-Carr | Many parts have downloadable 3D printable models | McMaster Carr | NA | NA |

| NASA | Site that hosts NASA 3D printable models | NASA | NA | NA |

| Smorf | A website that allows you to interactively render crystal structures on-line and buy 3D-printed models at $10/piece | Smorf | NA | NA |

| NIH 3D Print Exchange | A public website that enables users to share, download and edit 3D print files related to health and science | National Institute of Health | NA | NA |

Most Popular and Free for 3D Printing Collections:

- Thingiverse

- My Mini Factory

- youMagine Pinshape

- GrabCad

- X 3D Smithsonian

- NIH 3D Print Exchange

- GB3D Type Fossils

The UK repository for digitized type fossil specimens. - African Fossils

African Fossils seeks to increase public knowledge about prehistory by harnessing modern technology. Through digitizing otherwise inaccessible discoveries, the organization is dedicated to creating a growing repository of 3D models of significant fossils and artifacts, thus making them freely accessible to all. - Digital Morphology library

This collection of 3D models of fossils is generated at the National Science Foundation's multi-user CT lab - Human ear from McGill

- Turbosquid

- SketchFab

- Autodesk

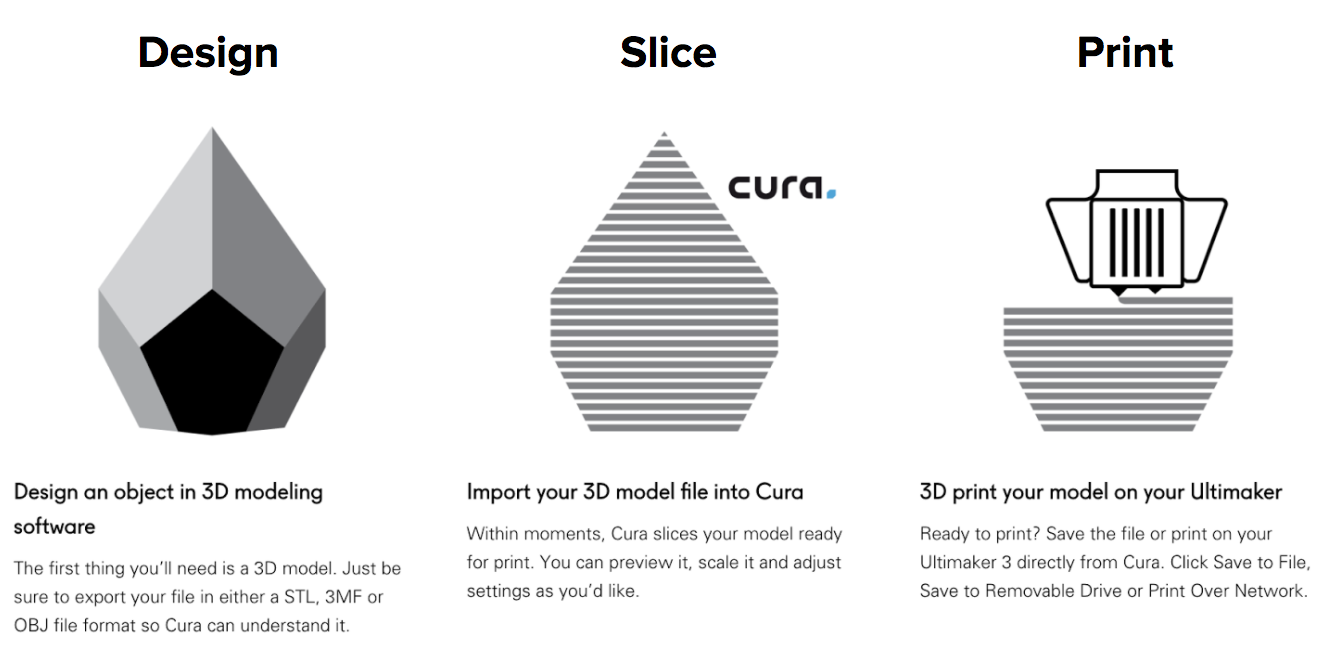

The 3 Steps to 3D Printing

You need the following to print

- A 3D model

- A slicer program, software to convert your STL, OBJ of 3mf file into G-code.

- A 3D printer

STL or STereoLithography or Standard Tessellation Language files describe the surface geometry of a 3D object and are used to build physical 3D CAD models. STL files are created using a mesh made of triangles that represents the surface, or physical part of your object. The STL file is a complete listing of the xyz coordinates of the vertices and normals—the vectors perpendicular to a surface that determine the orientation for the triangles—that describe the 3D object. The STL file can be opened with a text editor and you can see that it is just a list of triangles that rely of a set of points (known as 3D vertices).

A good STL file size is between .5MB for a simple file to 10MB for a large complicated one, or between 40K-1M faces. Generally, if your part is outside of these parameters, you'll need to resize it (to reduce the number of faces). A good STL file must also conform to two rules:

- The adjacent triangles must have two vertices in common.

- The orientation of the triangles (what side of the triangle is in and what side is out) as specified by the vertices and normals must agree.

Software to Repair Meshes:

| Tool | OS | File Formats |

|---|---|---|

| Autodesk Meshmixer | Windows, OS X, and Linux | amf, mix, obj, off, stl |

| Blender | Windows, OS X, and Linux | 3ds, dae, fbx, dxf, obj, x, lwo, svg, ply, stl, vrml, vrml97, x3d |

| FreeCAD | Windows, OS X, and Linux | brep, csg, dae, dwg, dxf, gcode, ifc, iges, obj, ply, stl, step, svg, vrml |

| MeshLab | Windows, Mac OS X, Linux, iOS and Android | 3ds, ply, off, obj, ptx, stl, v3d, pts, apts, xyz, gts, tri, asc, x3d, x3dv, vrml, aln |

| Autodesk Netfabb Cloud Service | Browser (Windows only) | stl, obj, 3mf and vrml |

| MakePrintable | Browser | 3ds, ac, ase, bvh, cob, csm, dae, dxf, fbx, ifc, lwo, lws, lxo, ms3d, obj, pk3, scn, stl, x, xgl, and zgl |

Blender

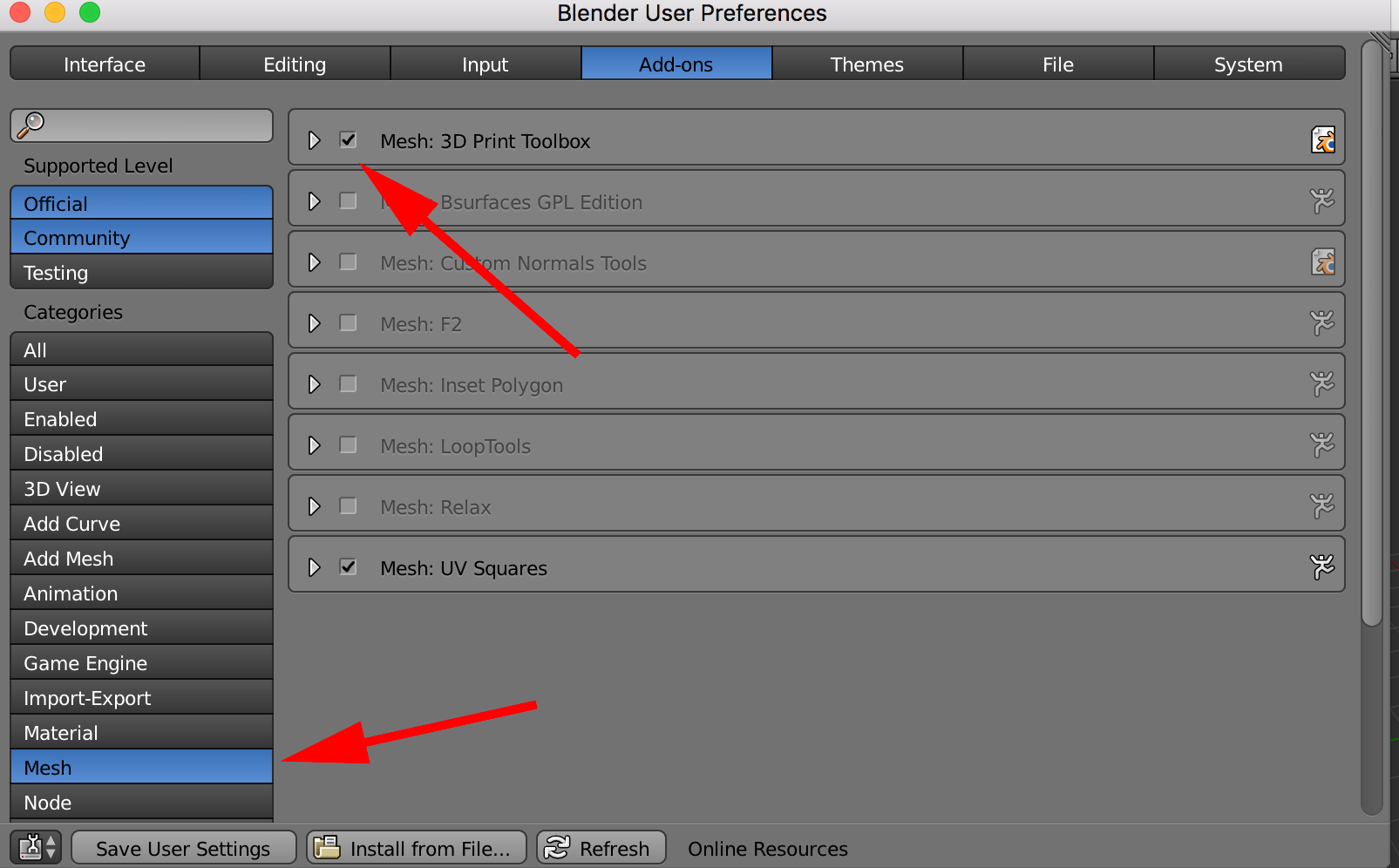

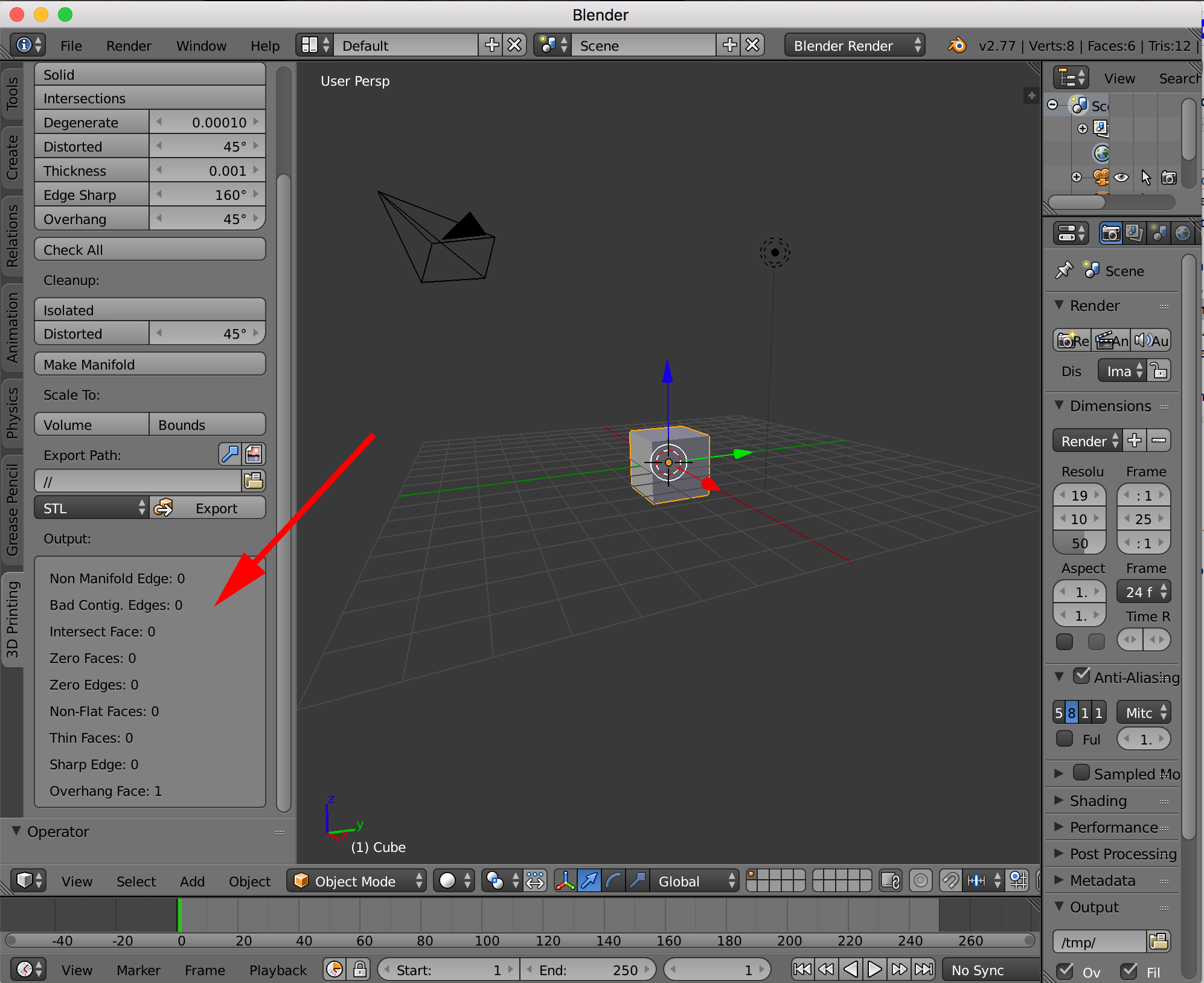

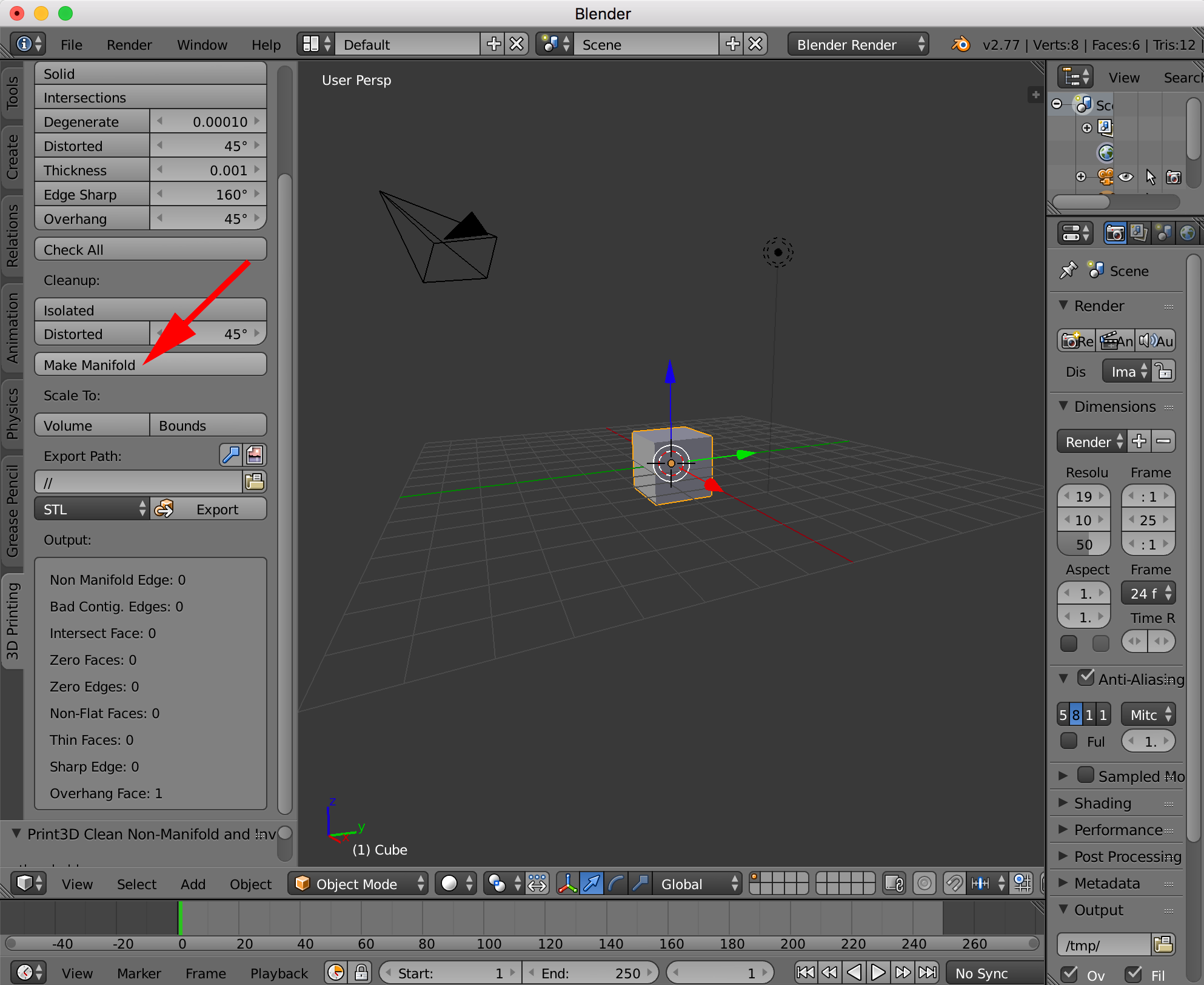

Apart from STL import, Blender offers a native STL repair tool.- Open the 3D Print Toolbox: File→User Preferences→Add-Ons (Cmd ,)

- Select Mesh and enable 3D Print Toolbox:

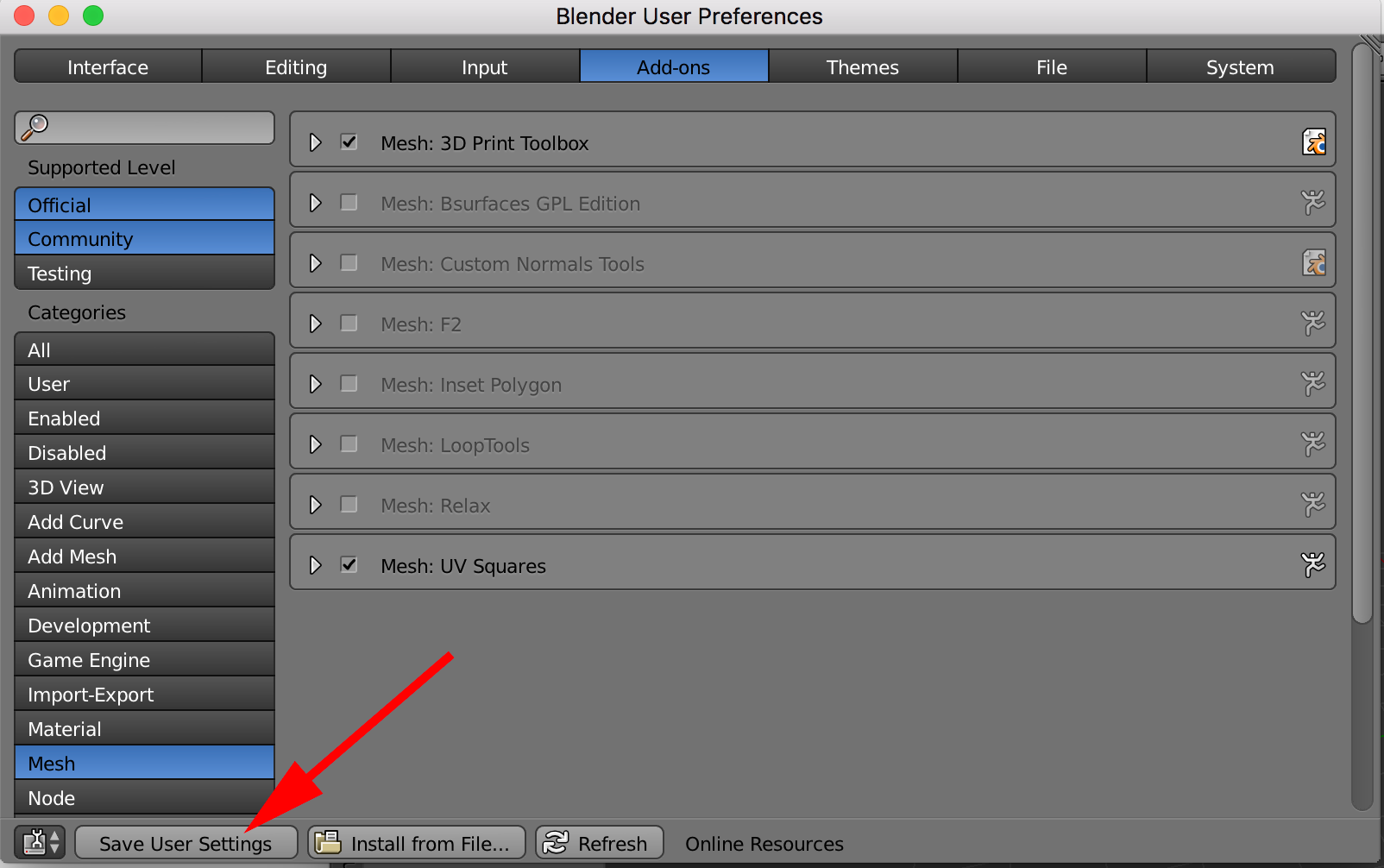

- Save User Settings:

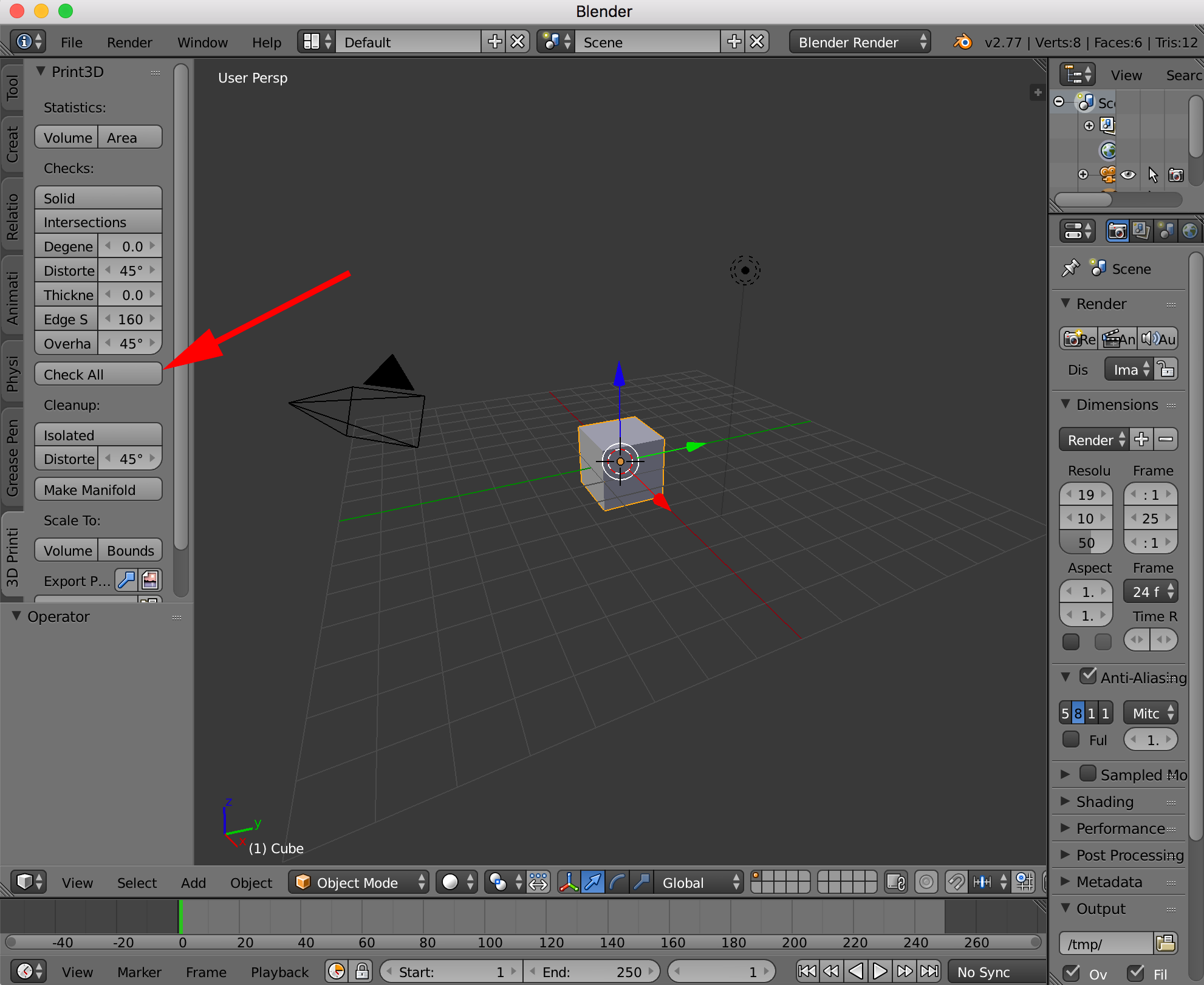

You can access the toolbox now in the left sidebar. - Blender's 3D Print Toolbox allows you to address all the issues that might cause your STL file to print incorrectly. The most pressing are:

- Overhangs that require support structure when printing with FDM and other techniques.

- Wall-thickness indicates areas that cannot be printed because they are too thin.

- Manifolds confound 3D printers with identical edges directly on top of each other.

- On the bottom of the toolbox appears a list of errors you can cycle through:

To repair vertices and edges press Isolated.

To make your mesh manifold press Make Manifold:

Meshmixer

- To import an STL file simply click on Import and browse for your object.

- Make your object solid.

Make your object solid. Alternatively, you can make it hollow. Click on Edit → Make solid. - In the sidebar, select Print. Here you find a comprehensive selection of tools that can help you prepare your STL file for 3D printing:

- To repair your mesh select Analysis and Auto Repair All.

This little tool will automatically fix all holes, non-manifold vertices, etc. - If you want to generate a support structure for your STL file, under the Overhangs option select Generate Support.

MeshLab

- To open a supported mesh file go to File→Import Mesh and browse for your model.

- To check if your STL file is watertight select:

Filters→ Quality Measures and Computations→Compute Geometric Measures.

You should see a volume for your file or an error report in the dialog on the right side. -

In case your STL file is not watertight, select

Filters→Cleaning and Repairing > Merge Close Vertices, click Apply.

Select Filters →Cleaning and Repairing →Remove Duplicate Faces, click Apply.

Select Filters →Cleaning and Repairing →Remove Duplicated Vertices. - Check your STL file again.

Instant Meshes

You can use Instant Meshes to reduce the number of faces of an obj file. Click here to see how the application works. An STL file can be termed bad because of translation issues. In many CAD systems, the number of triangles that represent the model can be defined by the user. If you are using too many triangles, the STL file size can become unmanageable. If you're using too few triangles to describe your object, your curved areas will not be properly defined and your cylinders might look like hexagons.What is G-code

Source: all3dp.com

Design Process

The Design Process requires:

- Research

- Design

- Building

- Testing

- Iterating

- Communication

The Basic steps

- Describe the general situation or problem you are trying to solve. Instead of asking "What do you want to design?" ask "Why do you want to design that?" and "What problem and or need will your design ultimately be solving?"

- Identify your target population, which group of people will benefit from your solution. Is the target population an individual, a group, a specific community, or a larger, identifiable population? Is the target population from a specific location (country, region, town), demographic (age or gender), or other identifying characteristics (health condition or employment)?

- Identify requirements and constraints. A requirement is a need or a necessity; it's what a particular product or service should do. A constraint is a restriction on the degree of freedom you have in providing a solution to a need or problem.

- Research/analysis

Ask what are the disadvantages of the present solution to the problem?

Ask what compromises have been made in the present solution?

Determine if the compromises are necessary?

Determine if the solution can be improved:- By taking a new approach.

- By making the design more accurate, safer, more convenient, easier to maintain, cheaper, or more attractive.

- Determine if you can reduce costs by eliminating parts, using different materials, changing the way the product is manufactured.

- Test

- Iterate

In a nutshell

- Design Step 1: Identify the Need

- Design Step 2: Research the Problem

- Design Step 3: Brainstorm Possible Solutions

- Design Step 4: Engineering Analysis-select the most promising solution

- Design Step 5: Construct a Prototype

- Design Step 6: Evaluate/Manufacture a Final Product-Reiterate

Example of a Design Challenge

Design Challenge: Design a prosthetic arm that can perform a mechanical function.You are working with a team of engineers from a biomedical engineering company that specializes in the design and manufacturing of prosthetic devices. Your team's challenge is to design a prosthetic hand that can perform ONE function to help improve the quality of life of the amputee who uses the prosthesis.

Example functions to design for:

- holding a pen or pencil

- clasping

- using sign language

- throwing

- brushing teeth

- picking up an object

- holding a utensil

- eating spaghetti

Design Constraints

Time: You will be expected to complete this design challenge from start to finish in a matter of weeks! Therefore, it is important to agree on a design that is functional, yet not overly complex.Other possible challenges:

- Lighting modifications to existing interior spaces.

- An assistive technology device.

- A water filtering system.

- Help a young child hold a pencil.

-Rajan Patel, former student of Sutton's at Stanford, cofounder of Embrace

Whatever the challenge is, you should always create a Design Document that:

- States the problem.

- Describes the solution, so with 3D printing, the project you will build.

- Identifies the parts that need to be designed.

- Includes sketches of the pieces and/or the model.

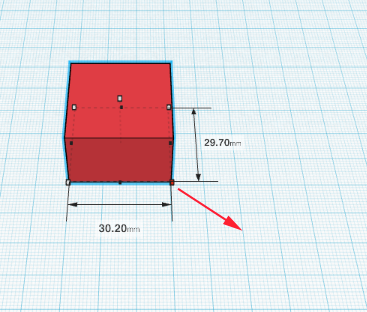

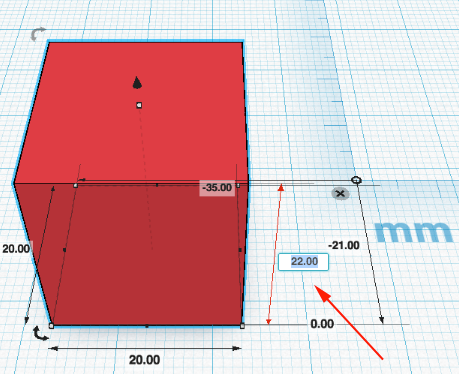

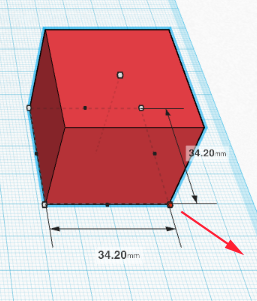

- Keeps track of dimensions so that you can track changes made over the process.

- Describes the division of labor (who does what).

- Keeps track of the progress.

- Keeps track of what is printed.

- Keeps track of testing and plans for iterating (keeps track of what changes will be made).

- Documents the final physical or virtual presentation.

Some Design Challenge Resources

- The Stanford Center on Longevity Design Challenge

- NASA DESIGN CHALLENGES AND COMPETITIONS

- Real World Design Challenge

- Design Kit from IDEO This is a great resources to help you through the process of designing your own challenge and

- IDEO's Design Thinking for Educators

Design Thinking for Educators Website

Design Thinking For Educators toolkit - IDEO's HCD [Human-Centered Design] ConnectThis resource was designed for NGOs and social enterprises that work with impoverished communities but includes methods relevant to education as well. The free kit walks users through the human-centered design process and supports them in activities such as building listening skills, running workshops, and implementing ideas.

- Embrace, an example of a challenge and its solution.

- d.school's k12 wiki

- How Are Universities Grooming the Next Great Innovators?

Stanford is one of the earliest higher education institutions in the country to apply design thinking across fields, equipping students with the ability and mindset to tackle difficult global problems in industries from healthcare to energy. In d.school courses, students observe, brainstorm, synthesize, prototype and implement their product ideas. "Students start in the field, where they develop empathy for people they design for, uncovering real human needs they want to address," notes the description on the d.school's website. - 27 Resources to Help Cultivate Design Thinking for Educators

- Extreme By DesignExtreme By Design, an hour-long documentary film, brings this revolution to life by following three university students as they design and build products to meet basic needs of the world's poor.

- Museum of Science, Boston Design Challenges

- Book: The Art of Innovation by Tom Kelley. In The Art of Innovation, Tom Kelley, general manager of the Silicon Valley based design firm IDEO, takes readers behind the scenes of this wildly imaginative and energized company to reveal the strategies and secrets it uses to turn out hit after hit.

- Book: Change by Design by Tim Brown

- Book: 100 Things Every Designer Needs to Know About People (Voices That Matter) by Susan Weinschenk

Book: 100 MORE Things Every Designer Needs to Know About People (Voices That Matter) by Susan Weinschenk

What is good design?

According to Lance Hosey in "Why We Love Beautiful Things" (Feb. 15, 2013) "brain scan studies reveal that the sight of an attractive product can trigger the part of the motor cerebellum that governs hand movement. Instinctively, we reach out for attractive things; beauty literally moves us."In his TED talk "The three ways that good design makes you happy," Donald Norman talks about how we respond positively to things we think are designed well.

The Princess Phone is a great example of the power of design. In 1955 a member of Bell System's merchandising department decided to make an institutional change. Instead of focusing on what the customer needed, the new direction looked at what the customers wanted. The result was the 1956 Princess Phone. The phone was the first of its kind: designed from a marketing perspective rather than from an engineering perspective. Aside from being lighter than previous models it also housed an internal light bulb so that the phone could be a bedside night light and aid in dialing in the dark. "It's little...It's lovely...It lights" was the advertising tag line. While there were many problems that came with the new design: the phone required an external ringer in a wall-mounted box, its base was too light and the weight it did have was unevenly distributed. Because it was somewhat difficult to use between dialing, holding the handset and keeping the phone on the table, it became known as the "three handed phone." Even with all its problems, the Princess Phone was, and remains, one of the most beloved telephone designs of all time.

Consider the products around you from tablets to websites to objects, to the metrocard system. We expect the products and services around us to be well designed, thought through, simple or streamlined, intuitive, elegant and enjoyable to use. What other products or services to you think are well designed? Which ones are poorly designed?

Here is a website that lists poorly designed objects. Can you add to the list? A Design Thinking Exercise

This is a simple exercise in design thinking.

We lose an ever expanding list of things, but let's focus on just a few small objects like keys, pens or pencils. The problem is that people have a tendency to lose or misplace these items.

Narrowing down this challenge may be appropriate:

But people have devised ways to store money for centuries. According to Wikipedia, the piggy bank, penny bank or money box is the traditional name of a coin container. To collectors, the piggy bank is known as a still bank as opposed to the mechanical bank that was popular in the early 20th century.

Historically, piggy banks were made of ceramic or porcelain. They were painted and served as a pedagogical device to teach the rudiments of thrift and savings to children: money can be easily inserted, but not easily removed.

Over the years plugs or stoppers were introduced for easier coin access.

The oldest money box ever found was from 2nd century BC from the Greek colony Priene, in Asia Minor. It featured the shape of a small Greek temple with a slit in the pediment. Money boxes of various forms have also been excavated in Pompeii and Herculaneum, and appeared quite frequently in late ancient provincial sites, particularly in Roman Britain and along the Rhine. Close exercise

- On a piece of paper write down a schedule of your average day from the moment you wake up to when you go to sleep.

5:58 a.m Wake up to cat biting toes 6:00 a.m. Alarm goes off 6:15 a.m. Get out of bed, brush teeth, get ready to go to gym 6:20-7:00 a.m. Exercise at gym 7:05 a.m.: shower, dress 7:25 a.m.: make coffee 7:30 a.m. unload dishwasher ...

- Now re-look at your list and find problems that arise at each task.

Jot down those problems. Not every item will have a problem.

5:58 a.m Wake up to cat biting toes cat wakes me up too early biting hurts 6:00 a.m. Alarm goes off alarm is too loud 6:15 a.m. Get out of bed, brush teeth, get ready to go to gym running low on toothpaste can't find toothpaste cap can't find matching socks 6:20-7:00 a.m. Exercise at gym too many people in gym, no room to exercise 7:05 a.m.: shower, dress 7:25 a.m.: make coffee coffee running low can't find filters no cream left 7:30 a.m. unload dishwasher I seem to be the only one that does this ...

- Now re-look at your list and jot down possible solutions to those problems. Not every problem will have a solution.

5:58 a.m Wake up to cat biting toes cat wakes me up too early biting hurts lock cat out of room 6:00 a.m. Alarm goes off too loud cover alarm clock with pillow 6:15 a.m. Get out of bed, brush teeth, get ready to go to gym running low on toothpaste need a way to order toothpaste when I see that I am running out can't find matching socks find socks the night before 6:20-7:00 a.m. Exercise at gym too many people in gym, no room 7:05 a.m.: shower, dress 7:25 a.m.: make coffee coffee running low need a way to maintain coffee supply can't find filters need a way to store filters and maintain supply no cream left need a way to remember when cream is running low 7:30 a.m. unload dishwasher I seem to be the only one that does this Need to find a way to encourage other family members to do this ...

- Select a problem/solution that might be solved by an object you can design.

- Make sketches with dimensions. Provide front, side and isometric views.

- Design a 3D model of your object

- Print

A Problem

After listening to Michael Gordon's Lost Objects (2001)—part 1 I began thinking about why and how people lose things, as well as how we use the the word "lose".We lose an ever expanding list of things, but let's focus on just a few small objects like keys, pens or pencils. The problem is that people have a tendency to lose or misplace these items.

The Design Challenge

Design a solution to this problem.Narrowing down this challenge may be appropriate:

- Design a means of locating an object.

- Design a means of locating an object in a bag.

- Design a solution that prevents losing the object.

- Design a solution that changes how we value and think about the object.

A Problem

How can you encourage an individual to save money?Background

According to About.com Inventors the old english word "pygg" referred to a type of orange clay that many useful objects were made out of. Around the 18th century someone thought to shape a "pygg" jar, to look just like the animal that the name conjured up.But people have devised ways to store money for centuries. According to Wikipedia, the piggy bank, penny bank or money box is the traditional name of a coin container. To collectors, the piggy bank is known as a still bank as opposed to the mechanical bank that was popular in the early 20th century.

Historically, piggy banks were made of ceramic or porcelain. They were painted and served as a pedagogical device to teach the rudiments of thrift and savings to children: money can be easily inserted, but not easily removed.

Over the years plugs or stoppers were introduced for easier coin access.

The oldest money box ever found was from 2nd century BC from the Greek colony Priene, in Asia Minor. It featured the shape of a small Greek temple with a slit in the pediment. Money boxes of various forms have also been excavated in Pompeii and Herculaneum, and appeared quite frequently in late ancient provincial sites, particularly in Roman Britain and along the Rhine. Close exercise

Science

Lesson Ideas

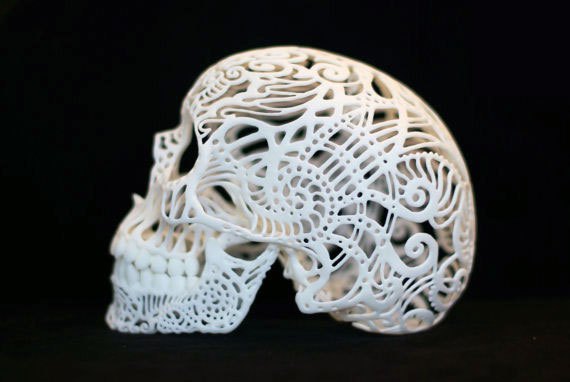

- Biology: Create your own species. Design a fossil or skeleton and determine its scientific classification.

- Biology: Print out bones, jaws,etc. and have students determine scientic classification

- Biology: Explore the story of how a child's skull, found in an ancient cave, helped answer one of our oldest questions: Where do we come from? Radio Lab's The Skull

Print the Taung Child Skull - Biology: How to 3D Print Proteins' guide

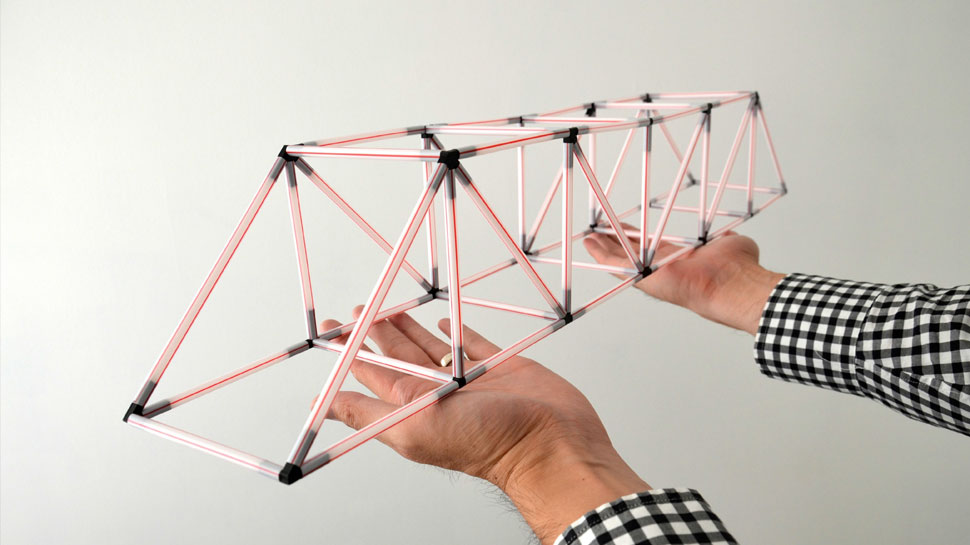

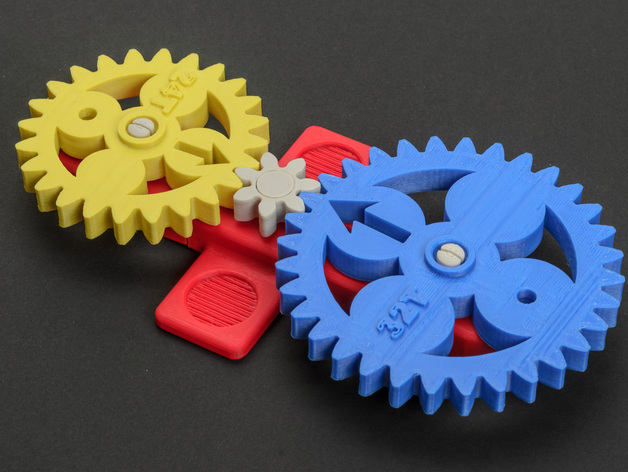

- Engineering Challenge: Recreate a model from the Reuleaux Collection of Mechanical Mechanisms at Cornell University

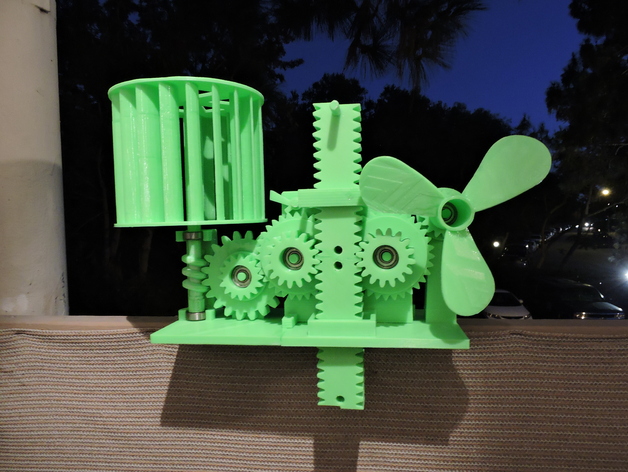

- Engineering Challenge: Create pieces for Rube Goldberg Contraption

- Engineering Challenge: Design a machine that implements at least one of the following:

- inclined plane

- lever and fulcrum

- wedge

- screw

- wheel and axle

- Pulley

- Explore Leonardo da Vinci's inventions.

- Engineering Challenge: Design a robot that can move forward using kinematics.

- Engineering Challenge: Design an automaton.

- Engineering Challenge: Design the tallest structure with moodular parts.

- Science and Engineering Challenge: Egg Drop Holder

Design an Egg Drop Container Using Autodesk 123D. - Balloon Racers.

- 3D and Museums

Please Feel the Museum: The Emergence of 3D Printing and Scanning by Liz Neely and Miriam Langer. - Light.

- Sound.

- Moving across water.

- DNA comb for a Gel Electrophoresis Separation

- Designing blades/Conservation of Energy

- LOW-COST 3D PRINTING FOR SCIENCE, EDUCATION & SUSTAINABLE DEVELOPMENT

LOW-COST 3D PRINTING FOR SCIENCE, EDUCATION & SUSTAINABLE DEVELOPMENT (iBook) - Option 1:

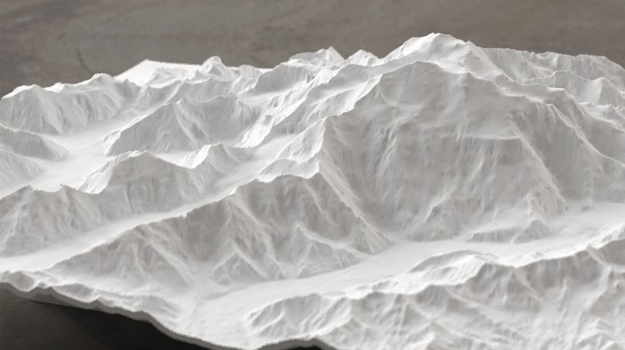

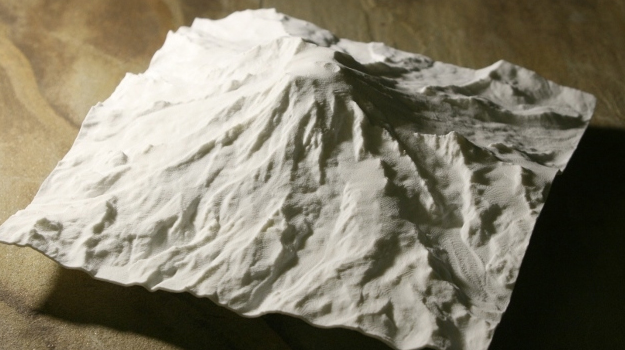

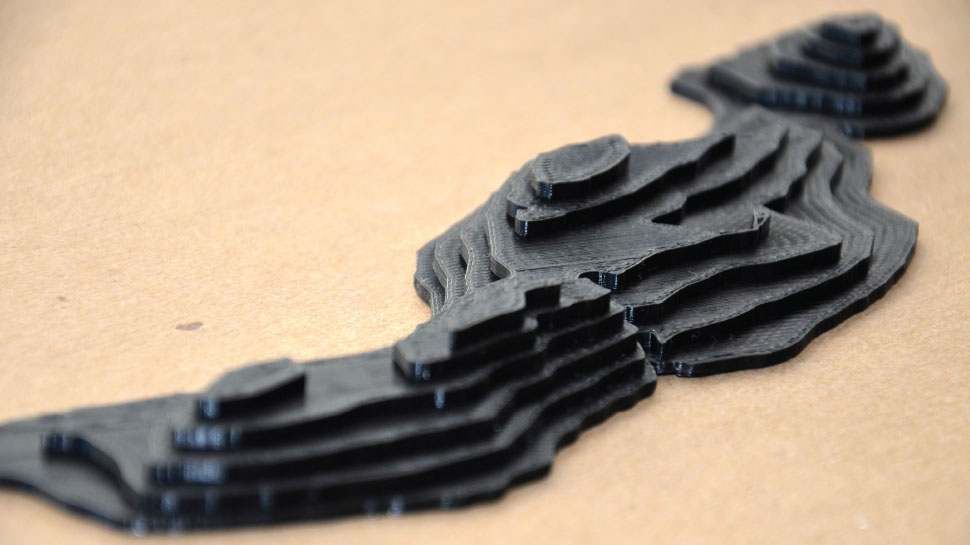

Topography

Option 2:

Topographical maps

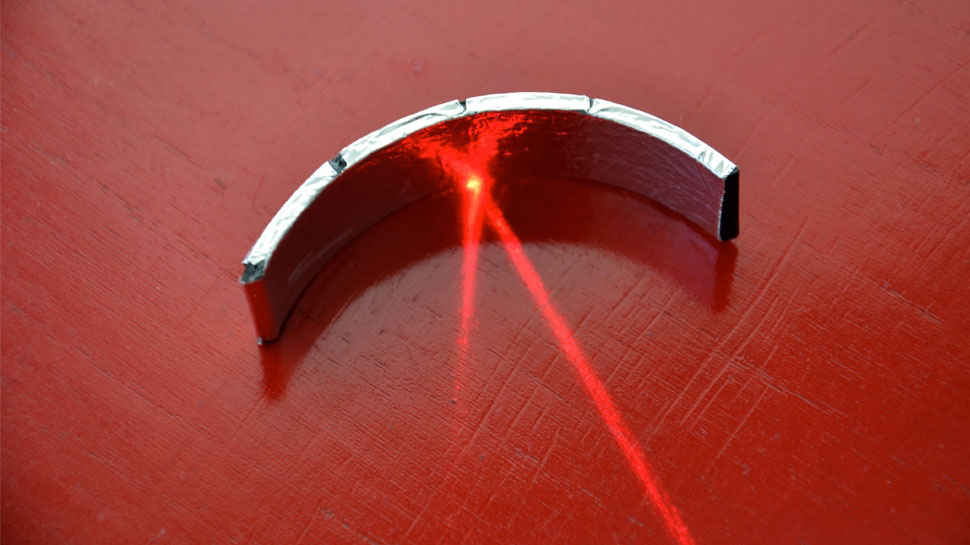

Optics

Mirrors

Filtration

Factors Affecting Reaction Rate

Crystal Growth- Option 1:

Bridge Design

Option 2: Modify this bridges assignment from BEAM, U.C Berkeley's Science and Engineering Outreach Program.

Density- GIS

Teachable Objects

- NIH 3D Print Exchange

3dprint.nih.gov is a community-driven resource, which provides access to a community-contributed database of bioscientific 3D printable files. Click here to browse or search the database.

The site is the result of a collaborative effort led by the National Institute of Allergy and Infectious Diseases in collaboration with the Eunice Kennedy Shriver National Institute for Child Health and Human Development and the National Library of Medicine.

Capture the Wind

Catch the Wind Competition

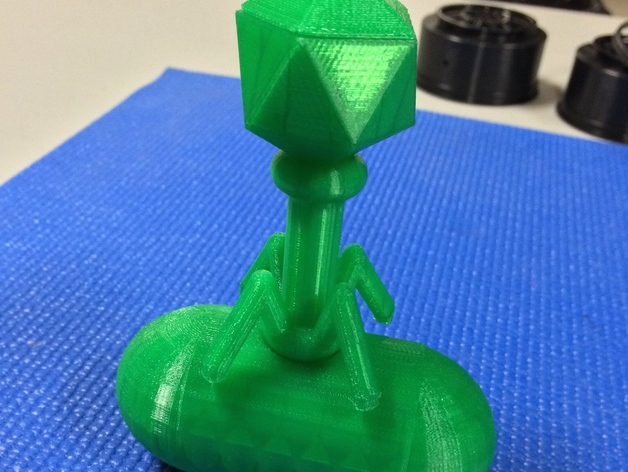

Educational Model of A Bacteriophage

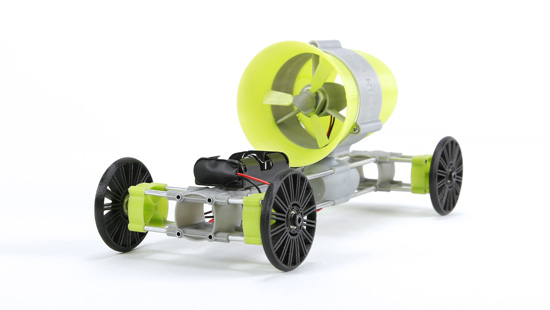

Jet Racer

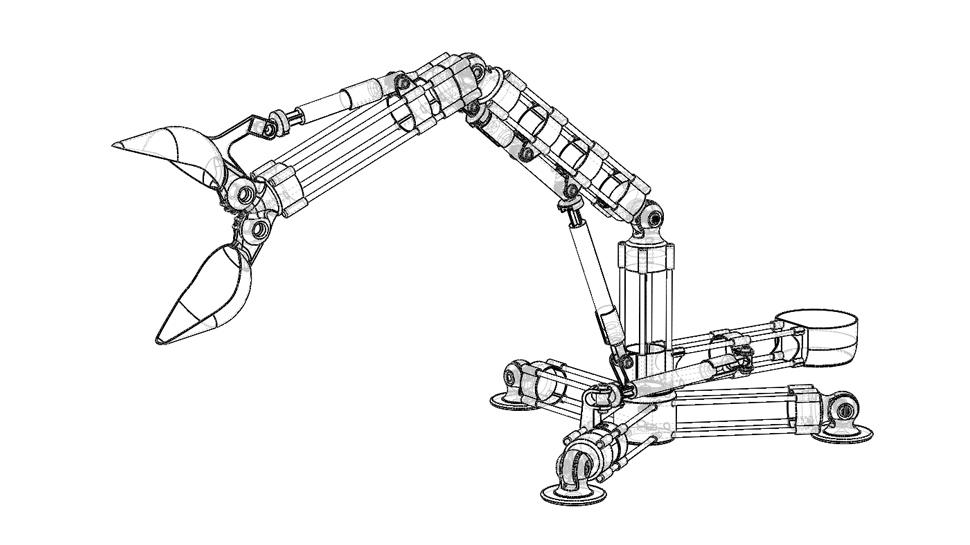

Articulated Arm

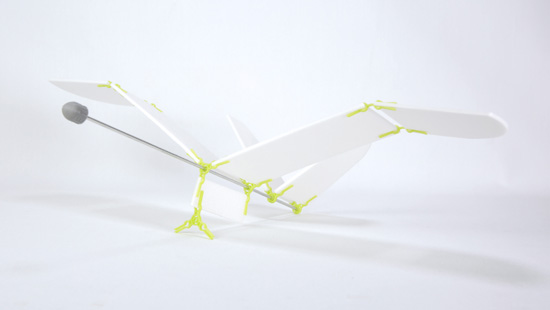

Foam Gliders

Dragon Fly

Infectious Pathogens

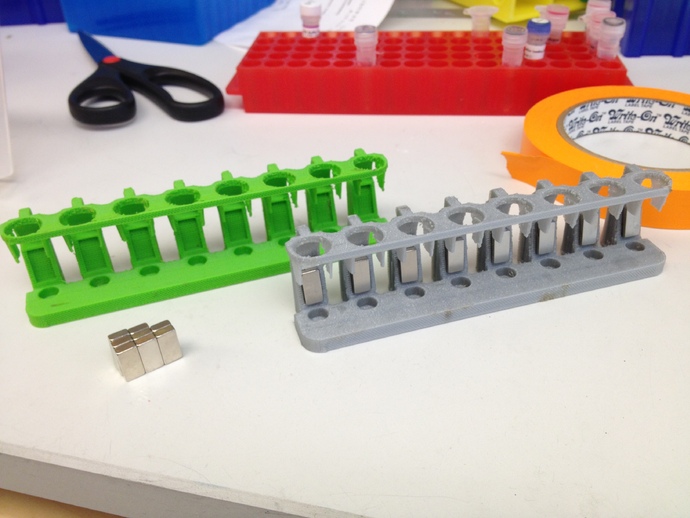

Magnetic Rack for 8, 1.5mL Tubes

Laboratory Pipette

Adjustable Volume Straw Pipette

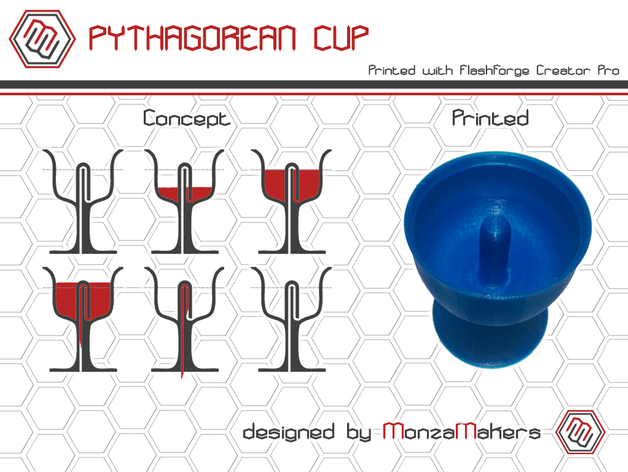

Pythagorean Cup

Gale Crater, Mars

Nematocyst

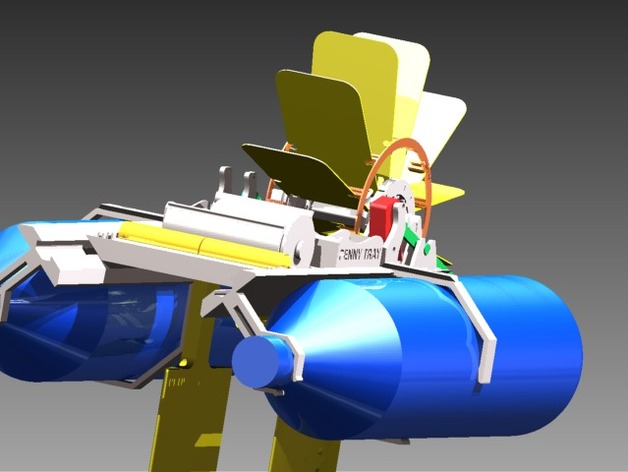

Paddle Boat

BodyParts3D Foot

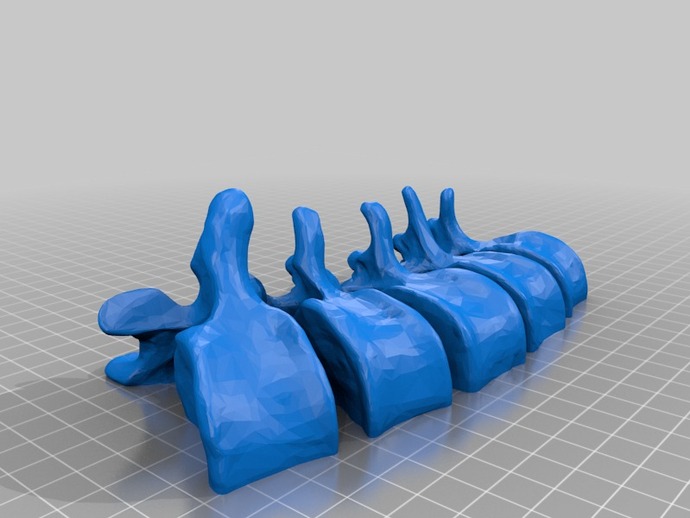

BodyParts3D Lumbar Vertebrae

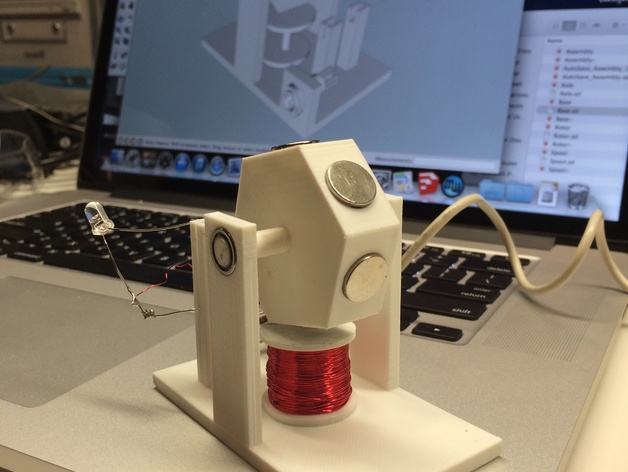

3D Printed Single Coil Pulse Motor

Additional Resources

The Future of 3D Printing Will Blow Your Mind!

Further Exploration

Source Materials

A BRIEF HISTORY OF 3D PRINTING (n.d.): n. pag. Web. 04 Jan. 2015MIT Toy Lab. 04 Jan. 2015

"Problem Solving." Nature 215.5106 (1967): 1119. Web. 04 Jan. 2015

"History of 3D Printing: It's Older Than You Think." LINESHAPESPACE History of 3D Printing Its Older Than You Are That Is If You're Under 30 Comments. N.p., 05 Sept. 2014. Web. 04 Jan. 2015.

"The History of 3D Printing: A Timeline | ZDNet." ZDNet. N.p., n.d. Web. 04 Jan. 2015.

CNN

Ducharme, Jamie. "MIT Produces Synthetic Bone With 3-D Printing." Boston Magazine. 18 June, 2013. Web. 04 Jan. 2015.

Groopman, Jerome. "Print Thyself. How 3-D printing is revolutionizing medicine." The New Yorker, 24 Nov. 2014. Web. 04 Jan. 2015.

LaFrance, Adrienne ."To help solve challenging cardiac problems, doctors at Children's press 'print'." The Washington Post, 13 May 2013. Web. 04 Jan. 2015.

"Stereolithography at Materialise." YouTube. YouTube, n.d. Web. 04 Jan. 2015.

"Fused Deposition Modeling (FDM) Technology." YouTube. YouTube, n.d. Web. 04 Jan. 2015.

"Selective Laser Sintering (SLS) Technology." YouTube. YouTube, n.d. Web. 04 Jan. 2015.

"Fabricated: The New World of 3D Printing." Skip Prichard Leadership Insights. Skip Prichard, n.d. Web. 04 Jan. 2015.

3D Printing Companies:

B9 CreatorDeltaPrintr

FormLabs

MakerBot

MiiCraft Orion Delta™ 3d Printer

OWL Nano™

Pegasus Touch

Solidator DLP Desktop 3D Printer

Tinkerine

Ultimaker

Companies/Publications:

continuumfashion.comnervous systems

3dprintingindustry

dezeen.com

Bespoke Innovations

nejm.org

solidsmack

Wired

Forbes

Makezine

trends.archiexpo.com

Databases:

Thingiverse

My Mini Factory

youMagine

GrabCad

X 3D Smithsonian

NIH 3D Print Exchange

GB3D Type Fossils

African Fossils

Digital Morphology library

Smorf

UK Natural History Museum

Human ear from McGill

Turbosquid

Harvard's Lewis Lab

nothinglabs.com

taulman3D

acuitydesign

Lulzbot

LeapFrog

Flex Eco PLA

Orbi-Tech

Shapeways

Homework

Create a pinterest board and collect 3D printed images that interest you.Terminology

ABS—Acrylonitrile Butadiene Styrene. A thermoplastic with resistance to high heat. This material is the same plastic found in LEGO bricks. ABS is impact resistant, very hard, but still flexible. Compared to PLA, ABS has a high shrinkage, which makes it harder to print with. ABS, PLA and CPE are common filaments used for Fused Deposition Modeling (FDM) and Fused Filament Fabrication (FFF).Additive fabrication/Additive manufacturing —The scientific or industry term for the more user-friendly term 3D printing. It is the process of joining materials generally by placing one layer on top of another with the purpose of creating solid objects from 3D data.

Belts—Toothed gear belts used to transfer movement from the motors to other parts of a machine.

Bowden tube—The tube that the filament moves through. When the filament drive mechanism is placed on a non-moving part of the 3D printer, the filament can be pushed into the PTFE (Teflon&tm;) tube. This configuration keeps the extruder light: the lighter the extruder, the quicker you can move the toolhead when not extruding.

Brim—This is the single-layer flat area around the base of the model, sometimes enabled in your slicer to ensure adhesion to the build plate. Unlike a skirt, a brim has a 0.00mm offset from your model. The brim is attached to your part and extends outward, like the brim of a hat. Use brims to stabilize small parts or isolated sections of a model.

Build Plate—The platform, sometimes referred to as bed, that the model is printed on.

Build Platform—What the build plate is supported by.

Build Volume—Also known as Build Envelope. The X, Y and Z dimensions of the printable area of your 3D printer. These dimensions define how large your 3D model can be.

CAD or Computer Aided Design—The use of a computer to create precise designs.

Coupling Collet—The white plastic sleeve that uses pressure and friction to hold the Bowden tube in place on the Ultimaker.

Drafting —The use of computer programs and systems to design detailed two- or three-dimensional models of physical objects.

Dual Extrusion—The ability to simultaneously print 3D models in two colors or with different materials.

Endstop—The switches that help protect the machine from moving past its intended range and damaging itself.

Extruder—The group of parts of the 3D printer which handles feeding and extruding of the build material.

Filament—The material used in Fused Deposition Method (FDM) or Fused Filament Fabrication (FFF) 3D printing.

Firmware—The software that runs on the electronics and controls the Ultimaker.

Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF)—The process of laying down certain melted thermoplastic materials and joining each layer together to form a shape.

G-code—The programming language used to tell a computerized machine tool what to make and how to make it. The code defines where the machine needs to move, how fast, and what path to follow.

Heated bed—The build surface warmed in order to keep the base of an extruded part from cooling (or shrinking) too quickly. 3D printers with heated beds usually yield higher quality finishing on prints. The heated beds are commonly made of of glass, ceramics, or metals like aluminum. The Ultimaker build-plate has two default temperatures. For PLA it automatically goes to 60°C, for ABS it is 90°C.

Hot end—The bottom of the extruder that heats up to melt the filament.

Infill—The mesh pattern inside the 3D print that provides structure.

Layer height—Also known as layer resolution, this is the thickness of one printed layer measured in millimeters. With a thinner layer height you will usually increase the quality of the print, leading to a smoother surface and more detail visible in the Z-direction of the model. The default layer height for Cura's Fast Print profile is 0.15mm.

Mesh—The term for the net of polygons that describes the surface of a 3D model. For example, an STL file is simply a description of a triangular mesh.

OBJ file—An acronym for Object File which is a frequently used file format used in 3D modeling software. This text-based geometry definition file format was first developed by Wavefront Technologies.

Overhang —This is the part of a 3D model that hangs in midair. Remember, you can't print in air. You can enable supports in Cura, design supports in your modeling program, or sometimes reorient your model to eliminate this issue. A rule of thumb is that you can successfully print an overhang of less than 45° unsupported.

Parametric—An adjective that means something is adjustable in all dimensions. A parametric model is one that can be resized and or distorted to suit the user's needs.

PLA—Polylactic Acid, a thermoplastic made from fermented plant starch (usually corn). It is an alternative to petroleum-based plastics. PLA is technically carbon neutral in that it comes from renewable, carbon-absorbing plants, and it does not emit toxic fumes when incinerated. However, PLA biodegrades slowly, with a minimum of 100 years, unless it is subjected to industrial composting. PLA has a very low shrinkage, which makes it ideal for 3D models and prototyping at home.

Print speed—The speed at which the print head moves while it is printing. Based on the print speed the amount of plastic that needs to be extruded will be calculated.

Positioning precision—The accuracy with which the print head moves in the X and Y direction. Instead of moving around in a perfect circle, the print head moves in steps of 12.5 micron.

PVA—Polyvinyl Alcohol is a water-soluble filament used as 3D printing material for support. It is generally used as one of the filaments in dual extrusion 3D printers. PVA filament must be stored with a drying agent, since it will absorb moisture out of the air very easily. PVA also decomposes above 200°C. PVA is fully degradable and is quick to dissolve. To speed up dissolving, apply heat and agitation.

Raft—This is the printing technique for adding removable support material at the bottom of a print in order to prevent warping. The raft itself is the horizontal latticework of filament located between the model and the build plate. Rafts can be useful when the bottom surface of a model is not completely flat or has difficulty adhering to the build plate. Rafts are also used to help stabilize models with small footprints.

Rendering —The process of producing an image based on three-dimensional data on a computer.

Resizing—The process of altering the size of your model.

Shell—The exterior layer of a 3D printed model.

Skirt—This is a line printed around the object on the first layer, but not connected to the object. This helps prime the extrusion and also gives you a moment to check and correct any bed leveling issues before printing starts. You can set the skirt's line count, distance and minimum length in Cura.

Slice—The single layer of a 3D printed model.

Slicer—The software required to convert an STL or OBJ file into G-code, the machine readable file needed by a 3D printer to reproduce the model. Slicers, like Cura cut the model into horizontal layers (slices) and generates the toolpaths needed to fill them.

Specifications—An explicit set of requirements to be satisfied by a material, product, or service.

STL file—STL, STereoLithography, or Standard Tessellation Language files describe the surface geometry of a 3D object and are used to build physical 3D CAD models. An STL file is created using a mesh of triangles representing the surface of the physical part of an object. The text file is simply a complete listing of all the x, y, and z coordinates of the vertices and normals—the vectors perpendicular to a surface that determine the orientation of the triangles—that describe a 3D object. Opening an STL file with a text editor lets you see that the file is just a list of triangles, based on a set of points (known as 3D vertices).

Support —Additional material which can be generated by your slicer to support the structure of the model which wouldn't have any stability otherwise. Support parameters can be adjusted in Cura.

Technical Drawings —rawings that contain geometric figures and symbols to convey the scope and details of a project.

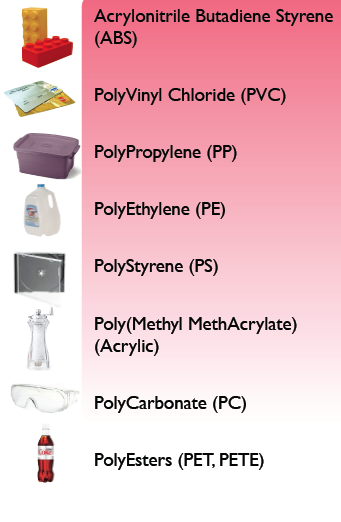

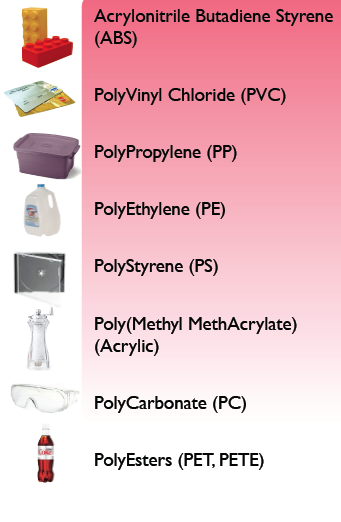

Thermoplastics—A polymer that becomes pliable or moldable above a specific temperature and returns to a solid state upon cooling. There are 8 common thermoplastics: Acrylonitrile Butadiene Styrene (ABS), Polyvinyl Chloride (PVC),Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), Polymethyl or Polymethacylate (Acrylic), Polycarbonate (PC), Polyesters (PET, PETE).

Travel speed—The speed at which the print head moves while it is not extruding any plastic.

Modeling Basics

List basic modeling techniques:

- Constructing primitives

- Drawing profiles

- Revolve

- Sweep

- Extrude

- Loft

- Shell

- Slice

- Union

- Intersect

- Subtract/Difference

- Fillet

- Chamfer

A brief history

Since the 1980's 3D Printing has been a disruptive technology, and 3D printers have been changing the way we create and learn.

Desktop 3D printers are affordable, personal fabrication tools, that allow anyone at any skill level to become a producer, an inventor, or an artist.

A very brief history

1983: Chuck Hull invents stereolithographySLA works by curing and solidifying successive layers of liquid photopolymer resin using an ultraviolet laser.

1986: Carl Deckard and Joe Beaman develop Selective Laser Sintering

Selective Laser Sintering is similar to SLA, but instead of liquid resin, powdered materials including nylon, ceramics, glass, aluminum, steel or silver can be used.

1986: 3D Systems is founded

Chuck Hull founds 3D systems, which develops its first commercial 3D printer, the Stereolithography Apparatus (or SLA-1)

1988: Scott Crump invents Fused Deposition Modeling

Fused Deposition Modeling heats and extrudes thermoplastic filament, depositing layers of semi-liquid beads along an STL-defined extrusion path.

1989: Scott Crump founds Stratasys

1990: DTM creates the first Selective Laser Sintering machine

Four Selective Laser Sintering machines were built, but none were ever sold. Each cost $300K-$400K.

1991: Helisys commercializes Laminated Object Manufacturing (LOM)

LOM bonds and cuts sheet material using a digitally guided laser.

1993: MIT licenses 3DP technology to several companies

MIT's Three Dimensional Printing (3DP) spreads a thin layer of powdered material on a flat bed, solidifying successive layers with fine jets of binding agent. MIT licenses its technology to several companies including Z-Corp.

1999: Anthony Atala leads team that successfully implants a lab-grown bladder into a human patient

Anthony Atala, director of the Institute for Regenerative Medicine at Wake Forest University School of Medicine, leads a research team that successfully implants a lab-grown bladder into a human patient. The organ is built by seeding a 3D-printed scaffold with bladder cells.

2005: Dr. Adrian Bowyer founds RepRap, an open-source project to create a Fused Filament Fabrication (FFF) machine

The aim of the RepRap (Replicating Rapid Prototyper) project is is to create a Fused Filament Fabrication (FFF) 3D printer that can print most of its own components. FFF instead of FDM is chosen to describe the process in order to avoid legal issues with Stratasys.

2008: The team behind Makerbot launches Thingiverse, a repository of designs for the 3D design community

Thingiverse was started in November 2008 by Zach "Hoeken" Smith as a companion site to what will become MakerBot Industries, a DIY 3D printer kit making company.

2009: Makerbot Industries is founded

Makerbot is founded by Bre Pettis, Adam Mayer and Zach "Hoeken" Smith. MakerBot builds on the early progress of the RepRap Project.

2011: Ultimaker is founded

Ultimaker is founded in the Netherlands by Martijn Elserman, Erik de Bruijn, and Siert Wijnia.

Types of 3D Printers

Stereolithography (SLA)

A process that works by curing and solidifying successive layers of liquid photopolymer resin using an ultraviolet laser.

Examples of Desktop 3D Printers are:

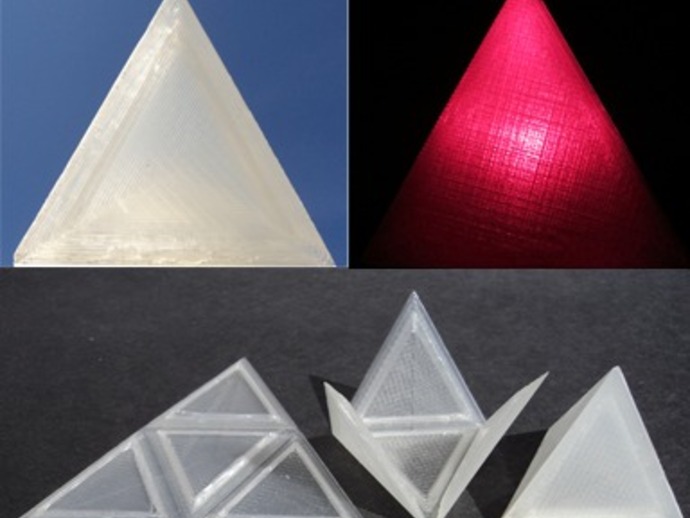

SLA models can:- be translucent

- have a high resolution

- have undercuts

- be large

- have high level of accuracy and details

The cons- The resin is expensive.

- Process only works with photopolymers which are not stable over time.

- Leftover resin can't be reused.

- Resin may cause skin, eyes and respiratory system irritation, and skin sensitization/allergic reaction by skin contact. Inhalation of high vapor concentration may cause headaches and nausea.

- Resin cannot be disposed of in drains, sewers, water supplies, or soil. You must dispose of the resin in accordance with all federal, state and local regulations.

- Printer must be used in well-ventilated area.

- You must wear impervious gloves (nitrile or neoprene) for routine handling. Aprons, long pants, and long sleeved shirts are also recommended.

- Chemical splash goggles or a face shield is recommended during operations where splashing could occur.

Digital Light Processing (DLP)

This process is similar to stereolithography in that it works with photopolymers. DLP uses a more conventional light source than SLA, such as an arc lamp, or a projector to cure photopolymer resin. The process is quicker than SLA because the projector cures the entire layer of resin at once.

DLP produces highly accurate parts with high resolution, but its similarities also include the same requirements for support structures and post-curing as SLA. One advantage of DLP over SLA is that only a shallow vat of resin is required to facilitate the process, which generally results in less waste and lower running costs.

Desktop exampleFused Deposition Modeling (FDM)

This process uses certain melted thermoplastic materials that are joined together to form a shape. As the material hardens, a 3D object is formed.

Desktop printers of this sort use Fused Filament Fabrication (FFF) technology. Examples of these 3D printers are:-

Selective Laser Sintering (SLS)

Similar to SLA, but instead of using liquid resin, powdered material is used. The material can be anything from nylon, ceramics, glass, aluminum, to steel or silver. The laser is traced across a bed of tightly compacted powdered material, according to the 3D data fed to the machine, in the X-Y axes. As the laser interacts with the surface of the powdered material it sinters, or fuses, the particles to each other forming a solid.

The build chamber is completely sealed as it is necessary to maintain a precise temperature during the process specific to the melting point of the powdered material of choice.

Examples of Desktop 3D Printers are:- Sinterit LISA desktop SLS printer ~$13,800.00

- Powder bed serves as support structure allowing for overhangs and undercuts.

- Parts made through this process are strong.

Key disadvantages- Requires high temperatures.

- Requires long cooling times.

- Porosity is an issue with this process, and some applications necessitate infiltration with another material.

- There can be surface inaccuracies.

- Sinterit LISA desktop SLS printer ~$13,800.00

Laminated Object Manufacturing (LOM) or

Selective Deposition Lamination (SDL)

LOM: In this process, to manufacture an object, plastic, paper and metal are glued together. After that, they are cut with a knife or a laser to give them a shape.

SDL: This process builds parts layer by layer using standard copier paper. Each new layer is fixed to the previous layer using an adhesive. A higher density of adhesive is deposited in the area that will become the part, and a lower density of adhesive is applied in the surrounding area that will serve as the support.

After a new sheet of paper is fed into the 3D printer, the build plate is moved up to a heat plate and pressure is applied. Pressure ensures the bonding between the two sheets of paper. The build plate then lowers and an adjustable Tungsten carbide blade cuts one sheet of paper at a time, creating the edges of the part. When cutting is complete, the 3D printer deposits the next layer of adhesive and so on until completion. Examples of Desktop 3D Printers are:- >Mcor ARKe (shutting down)

- >Mcor ARKe (shutting down)

Other Ideas

- Adornment challenge: Design pendants, bracelets or superhero rings.

- Puzzle Challenge: Design a puzzle comprised of 3 interlocking separate objects.

- Mr. Potato Challenge: Design a base and modular pieces to attach to the base.

- Ball and Socket: Create an articulated hand or foot.

- Animation Challenges: Design/Plan a possible stop motion animation that could use printed pieces.

- Animation Challenge: Create a face with pieces for the mouth, eyes and eyebrows that can be moved and synced to sound.

- Design Challenge: Lamp That— turn an object into a lamp.

- Design Challenge: One a Day—ideating, designing, modeling and making. Pick an object like a coffee cup and see how far you can push it.

- Design Challenge: Create a 3D model from a younger student's drawing.

- Design Challenge: Scan and modify a plush toy.

- Humanities: Create puppets and re-enact a reading or play.

- CyArk: Spurred by the Taliban's destruction of the 1600-year-old Bamiyan Buddhas in Afghanistan, CyArk was founded in 2003 to ensure heritage sites are available to future generations, while making them uniquely accessible today. Visit the website for 3D lesson plans

- CyArk is a non-profit organization that is working on creating digital replicas of the world's best known monuments, with the hope of capturing 500 in total. The idea is to map and preserve these monuments. The CyArk website also provides resources for educators.

- Interdisciplinary: Capture your town, neighborhood, school.

- Interdisciplinary: Urban Futures

Modeling Basics

Most common errors

- Model is not on bed

- bed leveling

- filament breaking in the tube due to it getting tangled

G-code

Slicing programs will convert your STL models into G-code, which is a numerical control or "Geometric Code" that tells a printer when, where, how to move and how much to extrude throughout the printing process.While you don't need to know anything about G-code, like with most other things in life, the more you know, the better equipped you will be. You can control every aspect of the printing process and understand what might be going wrong when troubleshooting. You can also get creative!

G-code is an easy programming language to read and write, as it is just a series of sequential statements and lacks programming constructs like variables, conditionals, and loops. Each line of G-code tells the printer to do a specific task. The printer executes the line one by one until it reaches the end.

Every line of G-code starts with a command. For a list of G-code commands see G-codes commonly found on FANUC and similarly designed controls. Commands are followed by arguments. Each argument tells the printer about how to execute the command. The arguments start with an English letter and then are followed by a numerical value. For example, X10.2 means a destination X coordinate of 10.2. F3000.0 means a Feed rate(F) of 3000.0. E0.02 means an Extrusion rate(E) of 0.02.

Commands which start with the letter G are geometric commands. They tell the printer head how to move. To turn the motor off or to raise the bed temperature, you need non-geometric commands. Non-geometric commands start with the letter M and are called M Codes. For example, the command M140 sets the bed temperature, and the command M190 tells the printer to wait for the temperature to reach the target. Each letter in G-code has a specific meaning.

| G | Standard G-code command, such as move to a point |

| M | RepRap-defined command, such as turn on a cooling fan |

| T | Select tool nnn. In RepRap, a tool is typically associated with a nozzle, which may be fed by one or more extruders. |

| S | Command parameter, such as time in seconds; temperatures; voltage to send to a motor |

| P | Command parameter, such as time in milliseconds; proportional (Kp) in PID Tuning |

| X | A X coordinate, usually to move to. This can be an Integer or Fractional number. |

| Y | A Y coordinate, usually to move to. This can be an Integer or Fractional number. |

| Z | A Z coordinate, usually to move to. This can be an Integer or Fractional number. |

| U,V,W | Additional axis coordinates (RepRapFirmware) |

| I | Parameter - X-offset in arc move; integral (Ki) in PID Tuning |

| J | Parameter - Y-offset in arc move |

| D | Parameter - used for diameter; derivative (Kd) in PID Tuning |

| H | Parameter - used for heater number in PID Tuning |

| F | Feedrate in mm per minute. (Speed of print head movement) |

| R | Parameter - used for temperatures |

| Q | Parameter - not currently used |

| E | Length of extrudate. This is exactly like X, Y and Z, but for the length of filament to consume. |

| N | Line number. Used to request repeat transmission in the case of communications errors. |

| *nnn | Checksum. Used to check for communications errors.letter. |

You can add comments to your code with a semi-colon:

G0 X-25 Y5 ; rapid movement to X=-25 and Y=5

Image: Make magazine

Image: Make magazine

G20/G21 or "set units"

G28 or "homing"

G28.1 X0 Y0 Z0 G90 or "absolute mode"

G0 X10 will send the machine head to the coordinate X=10.

G91 or "relative mode"

G91 G0 X10

G2 or "clockwise motion"

G21 G90 G17 G0 X6 Y18 G2 X18 Y6 I0 J-12

Image: Make magazine

G3 or "counterclockwise motion"

Image: Make magazine

Source: G-Code Tutorial for Beginners: Improve Your 3D Printing Skills

Material Science

Material Science is an interdisciplinary field which deals with the discovery and design of new materials. To move 3D printing beyond bracelets and toys requires the combination of efforts from individuals with backgrounds in computer engineering, mechanical engineering, robotics and materials science.

The more printing materials that can be developed, the more useful 3D technology will become.

Companies like Proto-Pasta are developing PLA based filament embedded with stainless steel, magnetic iron, and carbon fiber.

Jennifer Lewis, a materials scientist at Harvard University, is developing the chemistry and machines to take advantage of materials that are useful for their mechanical properties, electrical conductivity, or optical traits.

Researchers at Harvard's Lewis Lab are

- Developing ways to combine different 3D printing methodologies to achieve novel capabilities in the field of additive manufacturing of biological materials.

- Focusing on the design, fabrication and optimization of microfluidic printing devices as well as omnidirectional printing of ceramic materials and particle-laden fluids.

- Working on 3D printing of biological materials and architectures. Specifically, they are creating highly vascularized cell-laden tissue constructs and developing novel inks.

- Creating stimuli-responsive polymer inks for the 3D printing of adaptable, bioinspired materials and structures.

- Developing stretchable electronics using embedded-3D peverinting to pattern conductive fluid inks directly into highly stretchable viscoelastic matrices, allowing freeform fabrication of monolithic elastomeric electronic devices.

- Developing hierarchical composites by designing 3D printing inks with rationally designed microstructures.

- Developing piezoelectric and pyroelectric polymer inks to add a new tool into the 3D printing toolbox.

- Working at the intersection of electronics and biology to use 3D printing to simplify the production of Lab-on-a-Chip assays for high throughput drug screenings.

- Creating a tiny (the size of a grain of sand) 3D-printed lithium-ion microbatteries.

Polymers

What materials are used for printing now?

Technician Education in Additive Manufacturing & Materials' Materials for 3D Printing by Fused Deposition —this lesson includes lecture materials and demonstrations/activities for illustrating concepts related to polymer properties in 3D printing. A basic overview of polymer structure and behavior is followed by classroom activities, and then a more in-depth discussion of the specific polymers used in common fused deposition modeling (FDM) printers. The effects of chemistry and structure on the properties of the selected polymers are discussed, especially as they relate to the use of those polymers in FDM 3D printing.

Large scale printers, including those made by Stratasys can use different types of additive manufacturing materials, including clear, rubberlike and biocompatible photopolymers, and tough high-performance thermoplastics.

Here are examples of different printing processes:

- Composites and Ceramics

- Powder bed and inkjet head printers

This process uses inkjet-type heads to deposit tiny droplets of liquid binder on top of a thin layer of powder. The final object is a stack of powder layers finely glued together. This type of printing can use ceramic powder to create food-safe objects.

- Powder bed and inkjet head printers

- Plastics

- Stereolithography (SLA)

In this process liquid plastic resin is selectively hardened by exposure to high intensity light. - Selective Laser Sintering

This process uses high powered lasers to melt and fuse particles of very fine plastic powder - Photopolymer Jetting

This process uses moveable heads, like an inkjet printer, to deposit droplets of resin onto a build platform through a number of very small jets.

- Stereolithography (SLA)

- Metals

- Direct Metal laser sintering (DMLS)

This process uses lasers to directly fuse certain metal powders, such as titanium, in a way similar to SLS printing. - Direct Metal Printing

This process uses a multi-step method to create powder-based metallic models, mainly from stainless steel. First the object is printed on a bed of fine stainless steel powder using the inkjet-binder process. A carefully controlled heat treatment then burns out the plastic binder and fuses the steel particles together. Lastly, the porous sintered model is infused with liquid bronze, which fills the empty spaces. - Indirect Printing Methods

This process uses casting methods to create metal parts.

- Direct Metal laser sintering (DMLS)

Image from web.mit.edu

Question: What are Polymers?

Polymers are long chains of repeating

molecules (monomers). Natural polymers include

proteins, starch and

cellulose.

Synthetic polymers are typically from hydrocarbons and are derived from crude oil. 6-10% of U.S. oil consumption goes towards generating synthetic polymers. That's approximately 2 million barrels a day (lawrence livermore, 2004; metabolix 2007).

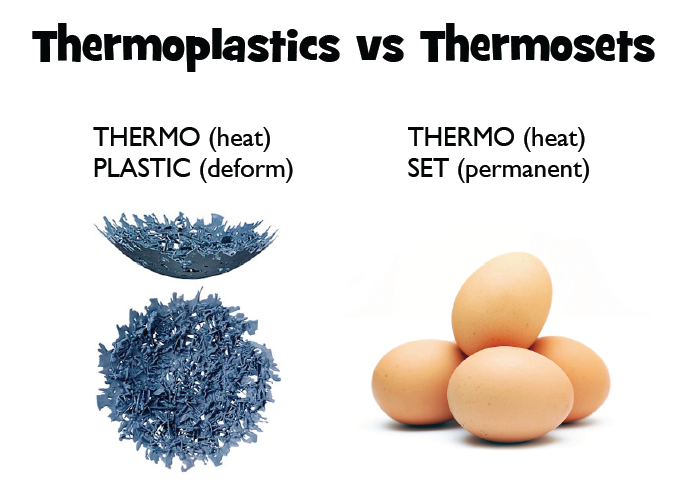

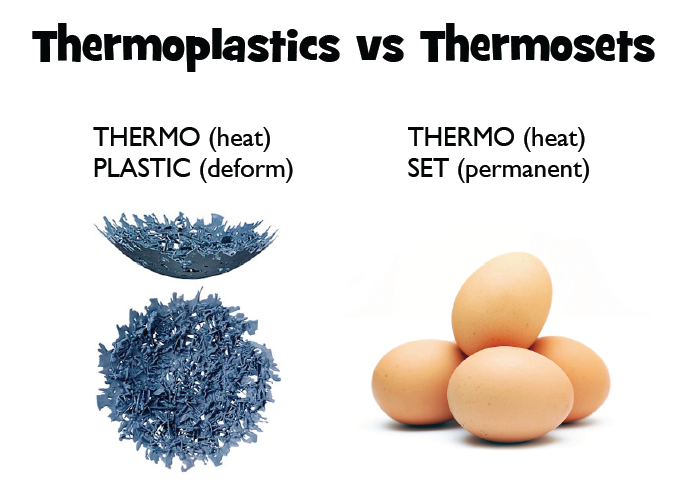

Thermosets are permanent and are used for high temperature, high tolerance, or joining. They are not recyclable.

Thermoplastics are common materials in toy manufacturing. Thermoplastics are easy to (re)shape with different processes and are mostly recyclable. There are 8 common thermoplastics:

PLA is technically carbon neutral in that it comes from renewable, carbon-absorbing plants, and does not emit toxic fumes when incinerated.

PLA biodegrades slowly unless it is subjected to industrial composting. Analysts estimate that a PLA bottle could take anywhere from 100 to 1,000 years to decompose in a landfill.

Synthetic polymers are typically from hydrocarbons and are derived from crude oil. 6-10% of U.S. oil consumption goes towards generating synthetic polymers. That's approximately 2 million barrels a day (lawrence livermore, 2004; metabolix 2007).

Thermosets are permanent and are used for high temperature, high tolerance, or joining. They are not recyclable.

Thermoplastics are common materials in toy manufacturing. Thermoplastics are easy to (re)shape with different processes and are mostly recyclable. There are 8 common thermoplastics:

So what is PLA?

Polylactic acid (PLA), is a thermoplastic made from fermented plant starch (usually corn). It is an alternative to petroleum-based plastics.PLA is technically carbon neutral in that it comes from renewable, carbon-absorbing plants, and does not emit toxic fumes when incinerated.

PLA biodegrades slowly unless it is subjected to industrial composting. Analysts estimate that a PLA bottle could take anywhere from 100 to 1,000 years to decompose in a landfill.

Here are examples of other filaments that can be used with Desktop FFF machines:

Ultimaker Nylon (polyamide) Ultimaker Nylon is strong, abrasion-resistant, durable and engineered for low moisture sensitivity. taulman3D t-glase t-glase (called TEE-GLASS) is an "optically correct" or water clear polymer that comes in Clear, Red, Green, Blue, White, Black and Aqua. Red, Green, Blue and Aqua are translucent rather than opaque. t-glase is a food and beverage safe polymer and carries the recycle rating of "1". t-glase is one of the lowest shrinkage of the polyesters. With optical coatings, t-glase can appear as clear as a glass part. t-glase prints at 235-245C. One can easily print light guides or light pipes.Bridge Bridge Nylon is similar to Nylon 645 with excellent tensile and low friction surface. While similar to Nylon 645, Bridge is chemical resistant to most chemicals except chlorine, bromines and some petrols. Bridge Nylon is fully capable of thread tapping and machine tooling.

Warning: nylon may emit trace amounts of cyanide at high temperatures. Make sure you are printing in a well ventilated space. LAYWOOD-D3 This filament from Germany is a mixture of 40% recycled wood with a binding polymer. This wood/polymer composite allows the filament to be printed just like thermoplastic filaments – such as ABS and PLA – but gives your creation a wooden-like appearance.

Print between 175°C and 250°C. After printing, your object will look and smell like wood and it can also be handled like wood. After printing you can cut, grind and paint your creations similar as you can do with wooden objects. This filament sticks well to tape

Depending on the temperature at which LAYWOO-D3 filament is printed, it will take on a different shade of brown. This means that by intentionally varying the printing temperature, you can simulate a tree's growth ring effect. At 180°C your LAYWOO-D3 prints will have a light colour and at 245°C your print will become darker.

This filament comes unspooled, but you can print your own spool with

Here is a python script to simulate banding:

This filament has a much lesser carbon footprint than typical co-polyester 3D printer filaments. Printing with a 5% infill produces a flexible model, while a 100% infill produces a model with a vulcanized rubber-like quality. You can use this filament to create molds, drive belts, toys, etc.

Print at 230°c and slow down the printing to 20mm/s. You will need to create a custom profile in MakerWare in order to use this filament.

Orbi-Tech, a filament-maker in Germany makes BendLay, a 3D fibre that is tough, bendable and resilient. BendLay's transparency is similar to that of Plexiglass. It can be extruded between 215° - 240°C, with 240°C recommended for best layer adhesion during fast printing. It's thermal stability is like PLA (65° - 70°C).

A modified Butadiene, BendLay is not a material found in nature, but it is safe for household and food products. Its water absorption rate is 30% that of ABS (this matters, because evaporation contributes to warping/curling). Bending will not cause the clear color to change due to stress. It is high-impact resistant and sticks well to both ABS and PLA, for multi-material print jobs. Acetone will turn it crumbly.

Applications range from straps and belts to anything requiring flexibility, thin walls, or light emission. It is relatively easily bent, depending on wall thickness, and highly resilient.

Shapeways prints with a flexible, rubbery plastic material called Elasto Plastic. It features high impact resistance, flexibility and compression. The material is made of laser sintering powder and has a rough, grainy finish. It is quite strong when printed with thick features (greater than 5mm). Though not strictly water-tight, it can hold liquids, but it does not like high temperatures or fire.

Shapeways also can print with:

- Alumide, a brittle Nylon Plastic that's filled with Aluminum dust.

- Detail Plastic, an acrylic based polymer that can print fine details. Smooth and slightly shiny.

- Frosted Detail Plastic, a UV-cured acrylic plastic that prints fine details and walls. Smooth and translucent.

- Stainless Steel — surface is slightly pitted & rough.

- Sterling Silver (92.5% silver).

- Gold Plated Brass, highly polished material

- Full Color Sandstone, gypsum printable with color textures on the model surface. Feels like matte clay.

- Ceramics Food-safe glazed ceramics. Available in glossy and satin finishes, and a variety of colors.

Project Ideas

Mr. Potato Head

In teams of 3, using Tinkercad, create as many parts as you can that fit into a potato.Starting with how things work

Students develop deep understanding through inquiry driven project-based learning and through the creation of projects and products.- Design a whistleResearch how a whistle works, then design your own:

- Design a key-operated lock

Make to Learn

The advent of 3D printing and advanced manufacturing provides the opportunity to re-establish the vital interconnection among historically related subjects.The Lab School maxim, Make to Learn, is grounded in the premise that students learn through the design and fabrication process. A series of guiding questions provides an interdisciplinary framework for the Lab School. This framework is adapted from a course, Engineering in the Modern World, developed by Michael Littman and David Billington at Princeton. The adapted framework incorporates the following questions considered in science, engineering, and history classes:

- Scientists analyze, asking, "How does it work?"

- Engineers invent, asking, "What is it good for?"

- Historians reflect, asking, "What is the impact?"

Source:An Educational Framework for Digital Manufacturing in Schools by Glen Bull,Hossein Haj - Hariri,Rosa Atkins, Pam Moran

3D projects call for accuracy in measurements.

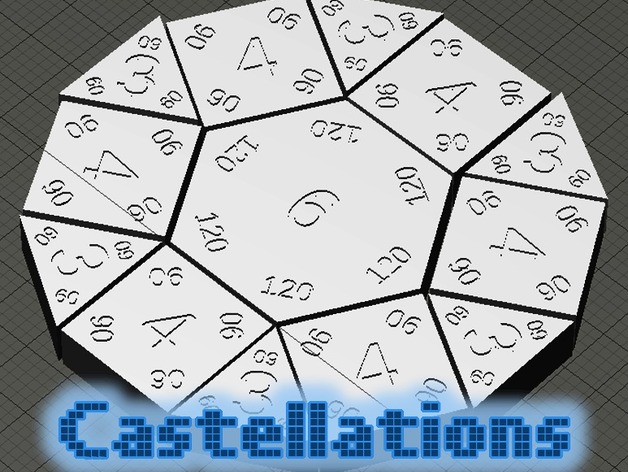

One Ultimaker Pioneer who works with elementary school students created a lesson around 3D puzzles. In order for the puzzles to fit together properly, students had to accurately measure their parts.Here are some other puzzle ideas

Constructionism

Professor Seymour Papert from MIT coined the word "constructionism" to describe the process of learning through doing. Constructionism differs from constructivism in that, while the latter is cognitive, constructionism is concrete. As Papert said, whether the artifact is a poem or a sand castle, it is through the building of something that true learning is demonstrated.- Brushbots

- Explore Voronoi diagrams

- Design a Fidget Spinner

Iteration

Sometimes the flaw is in the design itself, other times it is a flaw in the choice of materials or print density resulting in parts that lack the strength needed to work properly. It is through iteration that sudents discover their solutions.Math

Lesson Ideas

- Modeling Equations

- The Golden Ratio

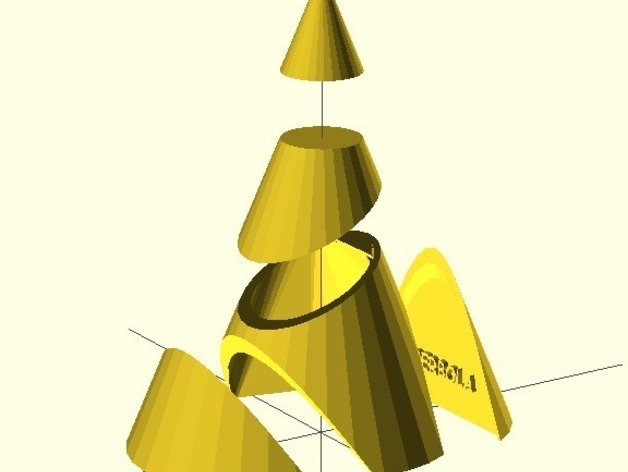

- Conic Sections

- Archimedean Solids

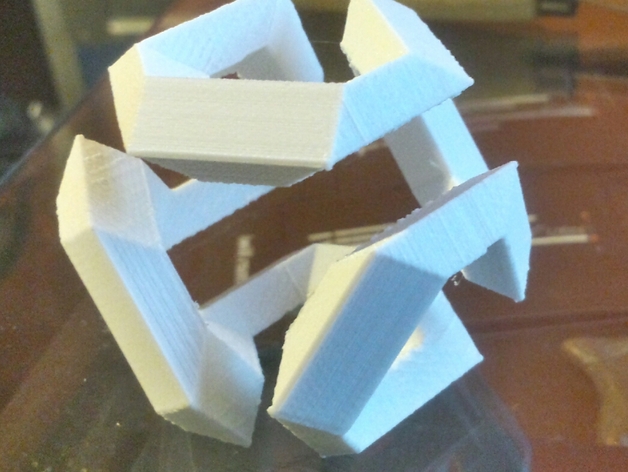

- Polyhedra

- Duality

- Snubbing Platonic Solids

- Cuboctahedrons

- Octahedrons

- Tetrahedrons

- Icosahedrons

- Finding the Area of a circle

- Catenary arches

- sphericons

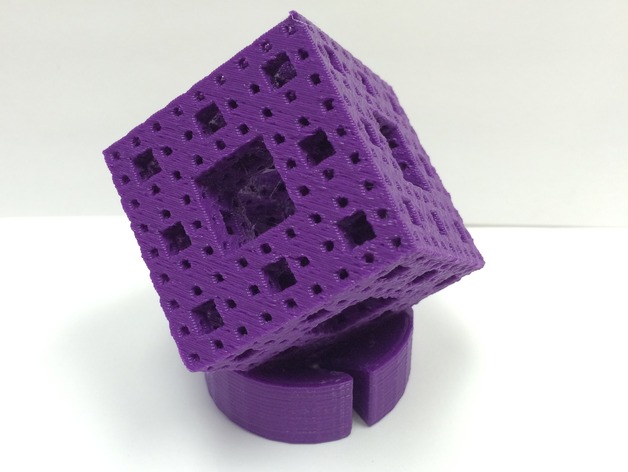

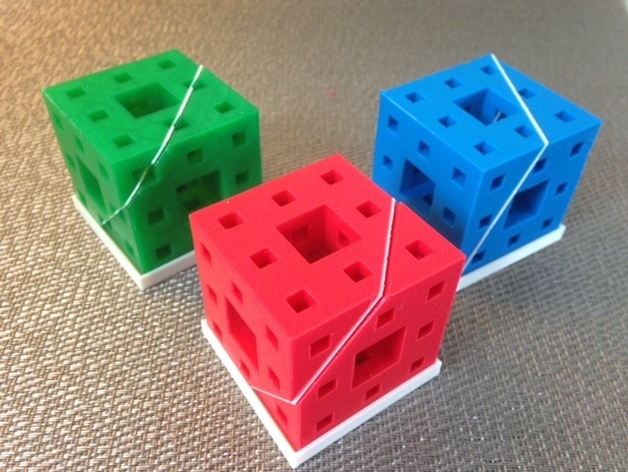

- Fractals

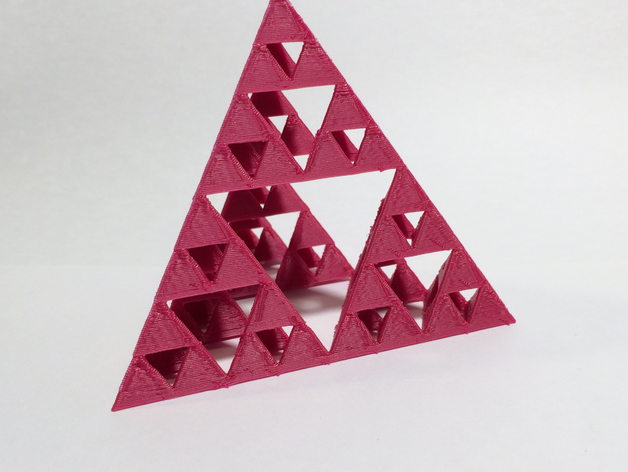

- Sierpinski

- Koch Snowflake

- Reuleaux Triangle

- Math Puzzles

- Manipulatives

- Voronoi

- 3D Printing and Mathmatica

- Surfcad is a python proof-of-concept CAD library written by Christopher Olah

- Explore fractals with Sierpinski Tetrahedron and the Menger Sponge

Mathematical Art at Shapeways - Explore hyperbolic paraboloids in a multivariable calculus class

f[u_,v_]:={u,v,u^2-v^2}; scale = 40; radius = 0.75; numPoints = 24; gridSteps = 10; curvesU = Table[ scale*f [u, i ] , {i , -1, 1, 2/gridSteps }]; curvesV = Table[scale*f[j, v], {j, -1, 1, 2/gridSteps}]; tubesU = ParametricPlot3D [ curvesU , {u , -1, 1} , PlotStyle -> radius , PlotPoints -> numPoints ] , PlotRange -> All ] ; tubesV = ParametricPlot3D [ curvesV , {v , -1, 1} , PlotStyle -> radius , PlotPoints -> numPoints ] , PlotRange -> All ] ; Tube [ Tube [ shape of the object than a blank, featureless surface does, and it also communicates mathematical content in terms of the parameterisation. Third, it can be useful to be able to see partially through the surface to other features behind it. 3.3 Mathematica code Here is the code to generate the graphical output shown in Figure 7a, together with the STL file. corners = Graphics3D[Table[Sphere[scale f[i, j], radius], {i, -1, 1, 2}, {j , -1, 1, 2}] , PlotPoints -> numPoints ]; output = Show[tubesU, tubesV, corners] Export["MathematicaParametricSurface. stl", output] - Cryptography

Teachable Objects

Deluxe Math Spinner

Math Gears

Castellations

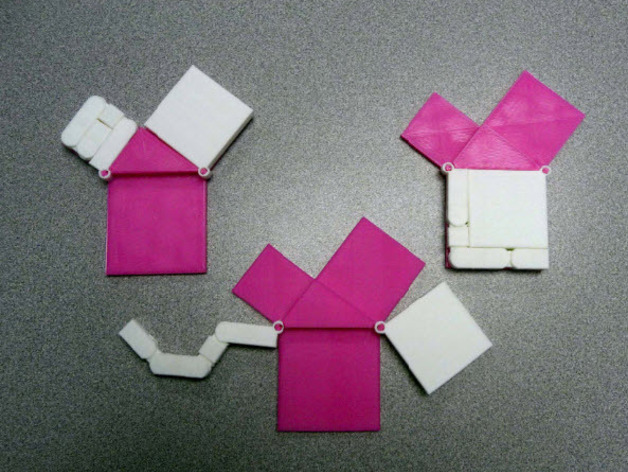

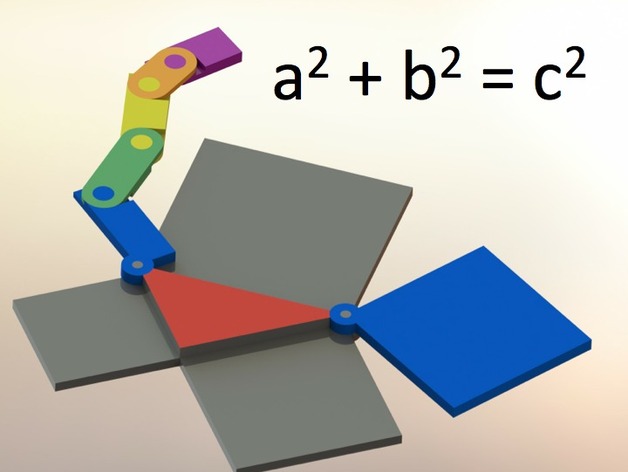

Pythagorean Theorem

Pythagoras Prints a Proof

Trefoil Menagerie

Apollonian Cone

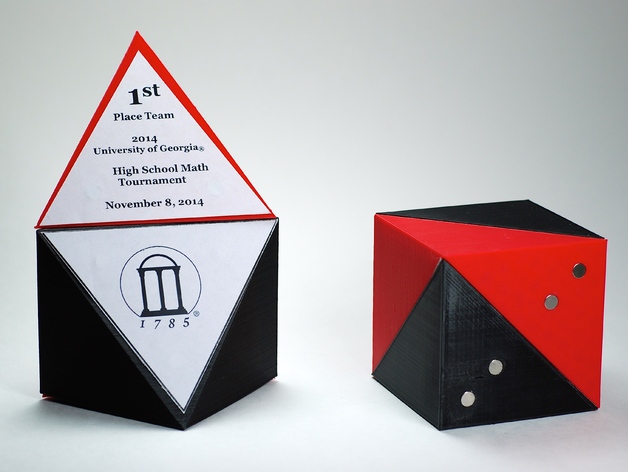

Cube Decomposition Trophy

Hamiltonian circuit/cycle

3D Printing for Math Professors and Their Students

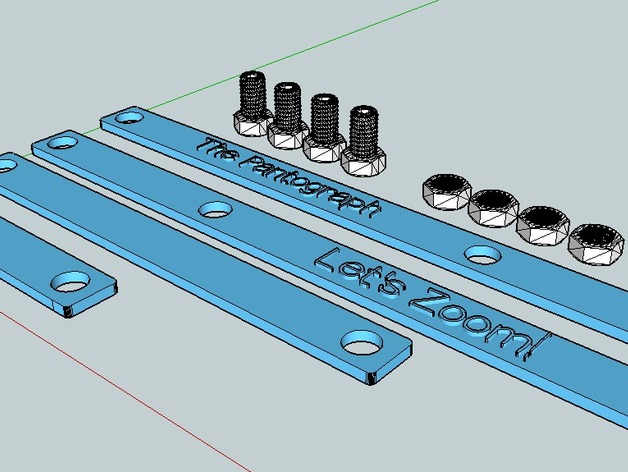

Pantograph

Hinged Triangle-Square

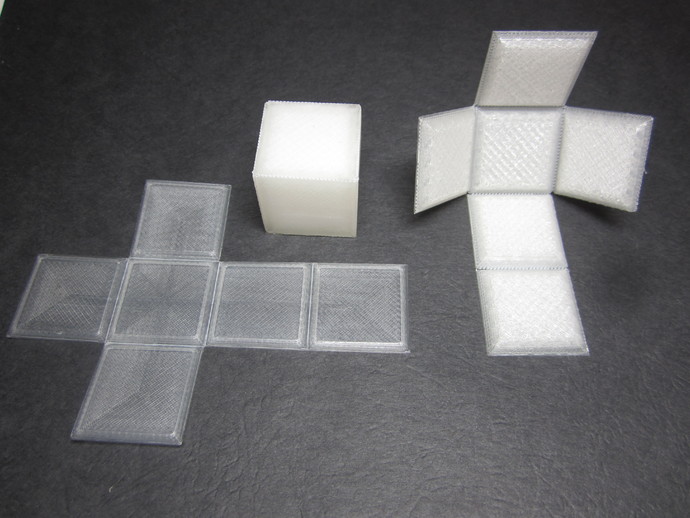

Foldable Cube - Print Flat

Foldable Tetrahedron - Print Flat

Customizable Menger sponge

Menger Slices

Customizable Sierpinski tetrix

Rocking Knot

Reflection Symmetry

Gears

N-sphere

What kind of tools are available?

For a complete list of software choices see Ultimaker's savvy 3D educator's superlist for Software Choices.

A smaller list to get you started:

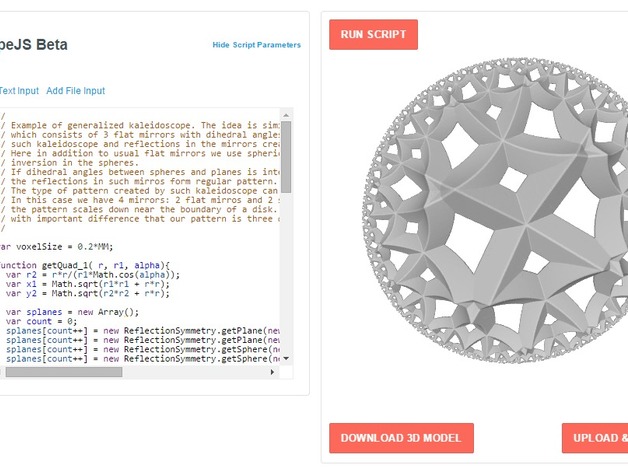

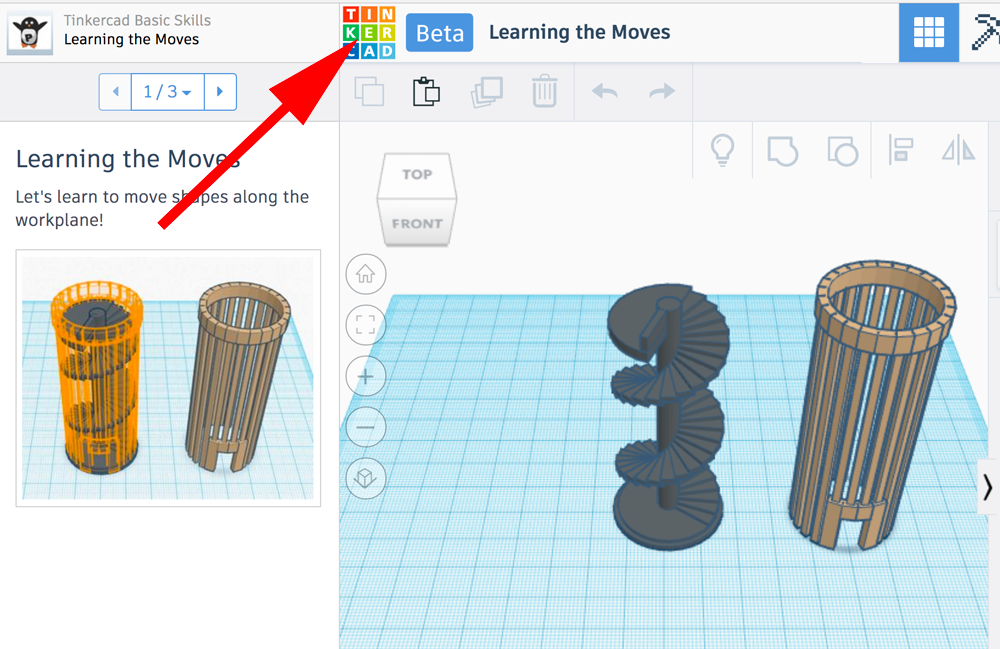

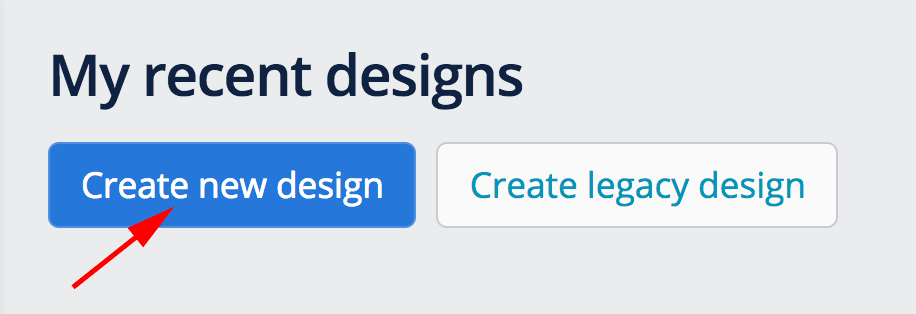

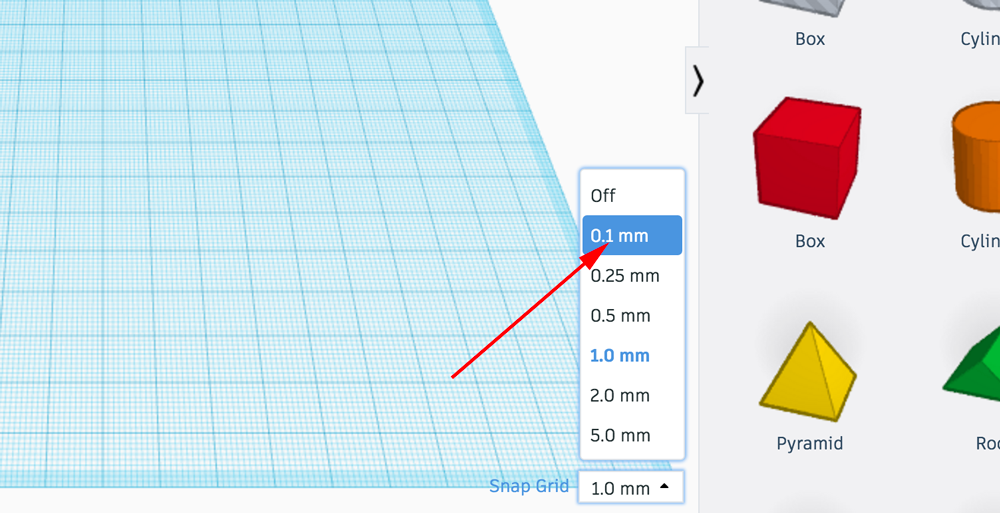

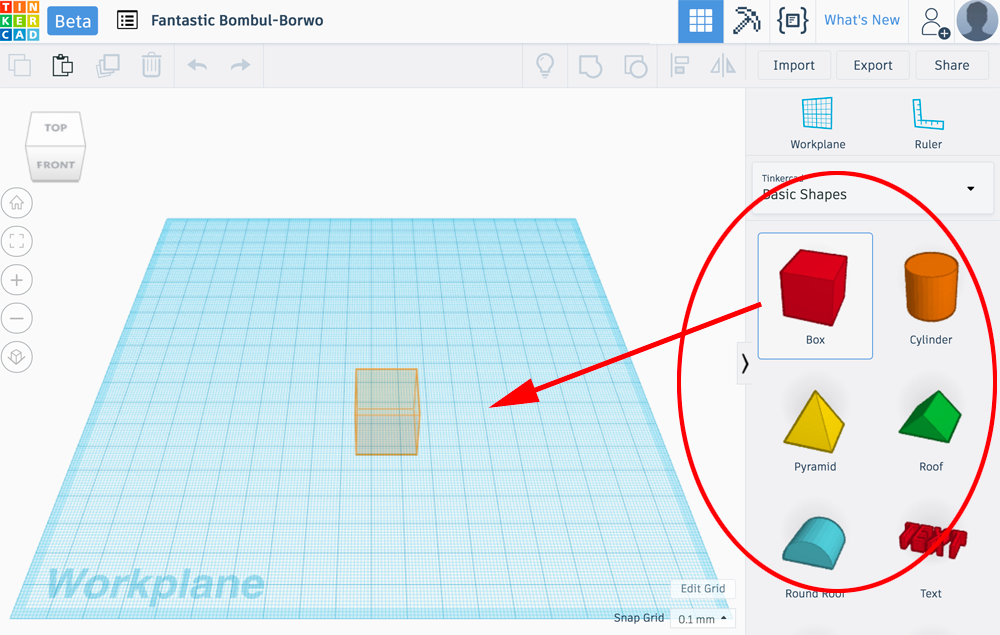

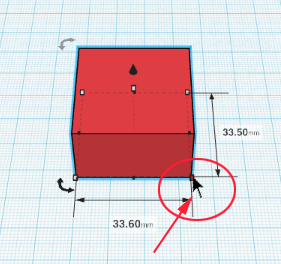

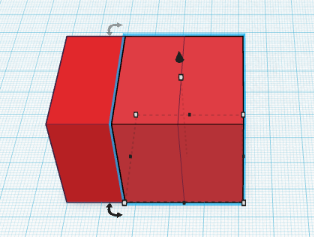

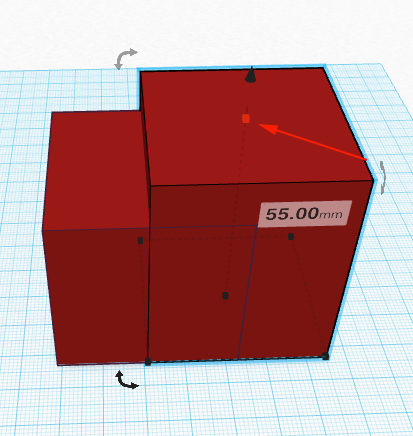

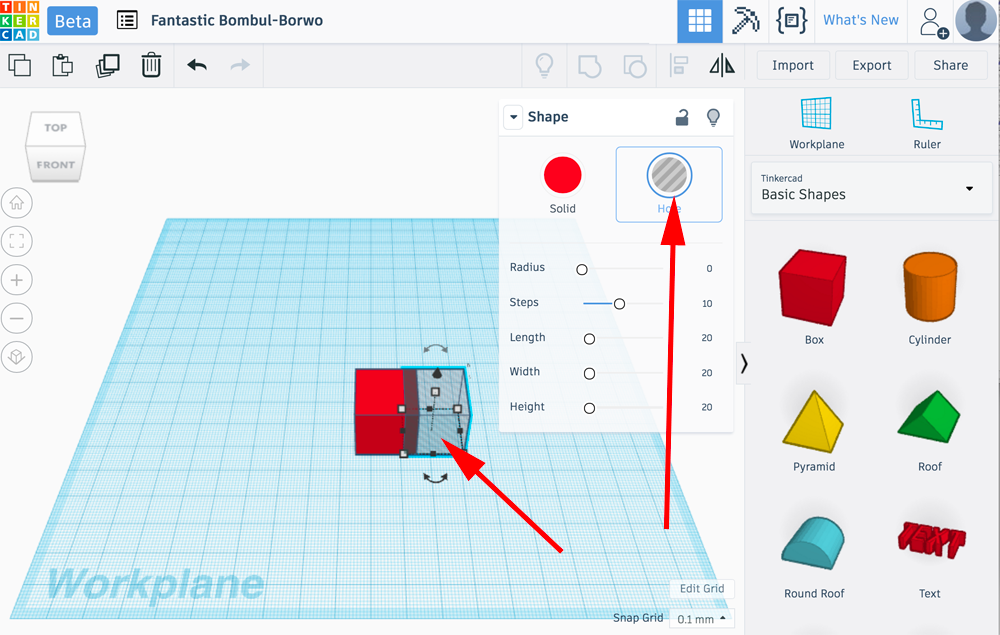

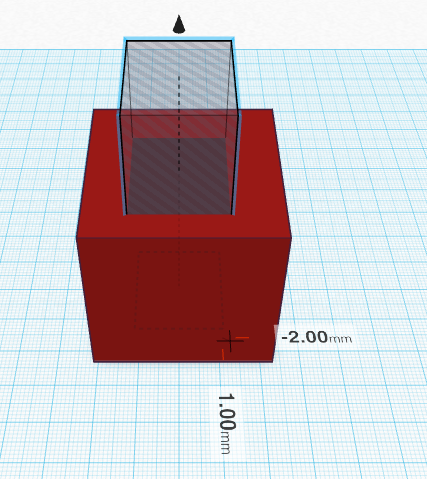

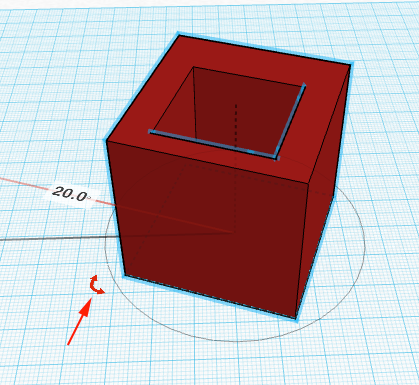

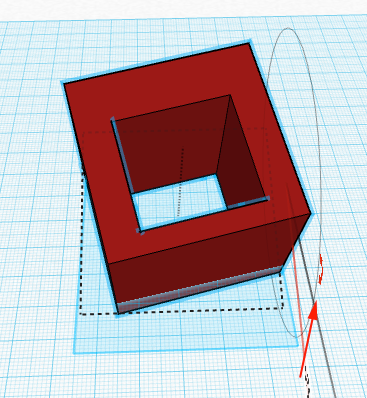

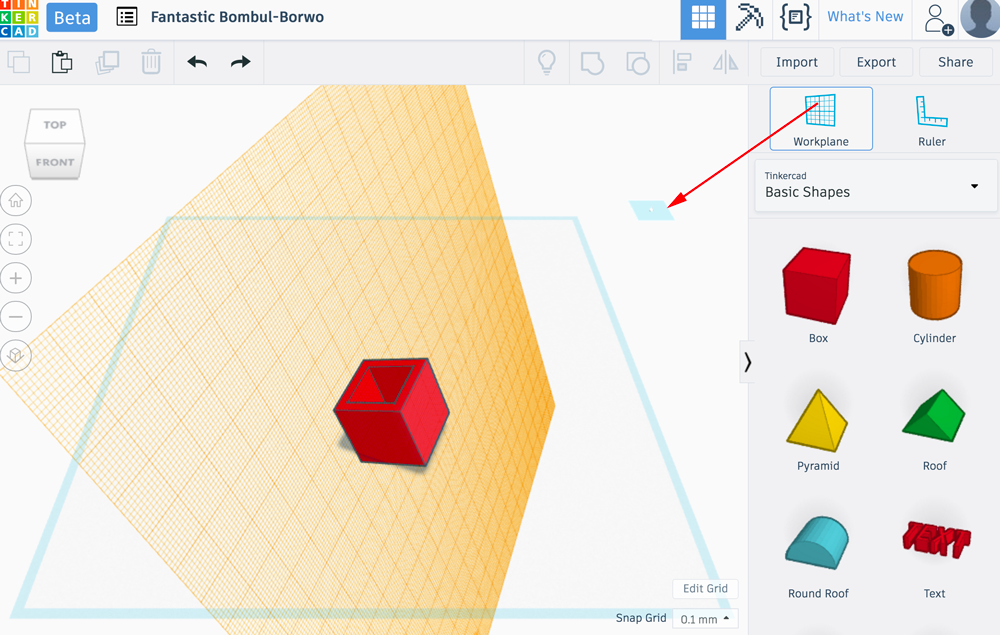

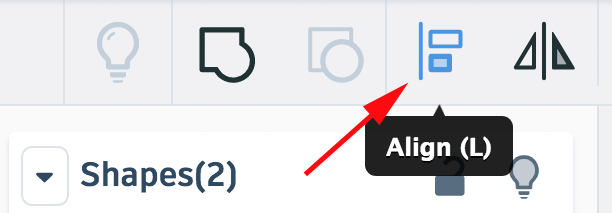

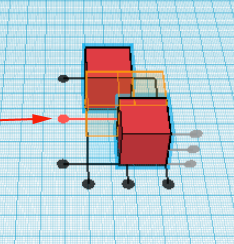

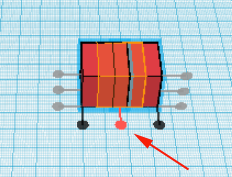

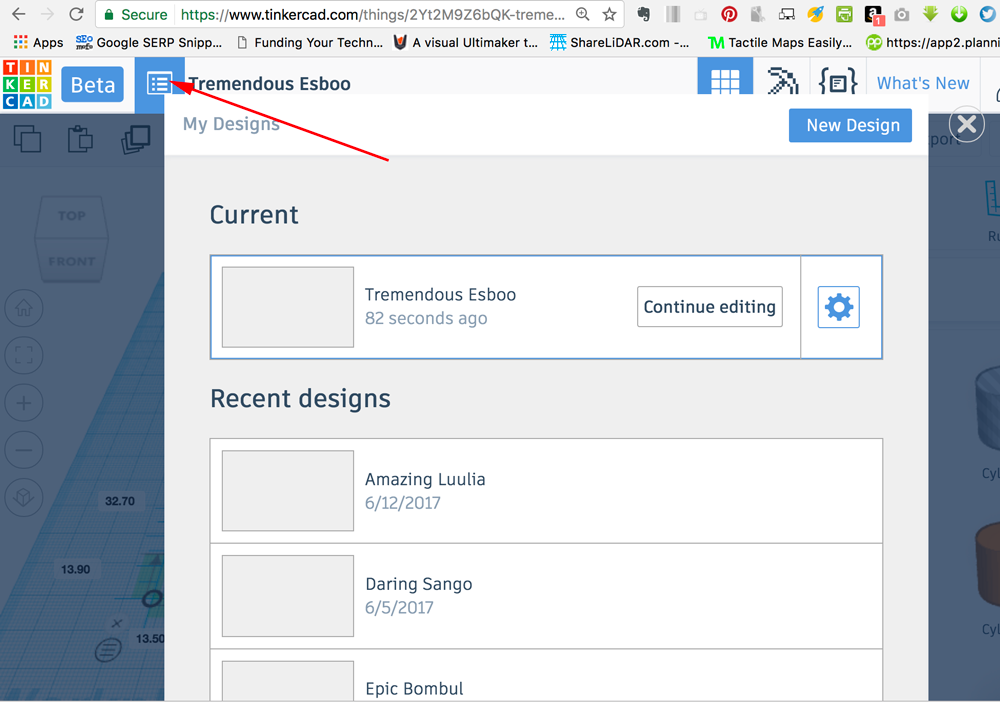

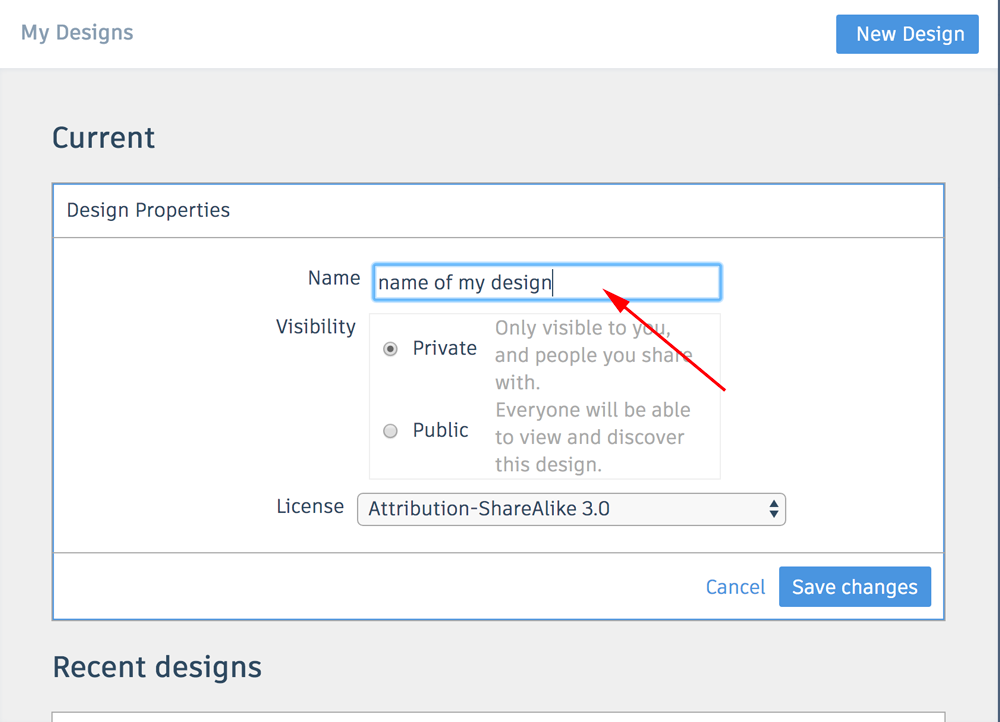

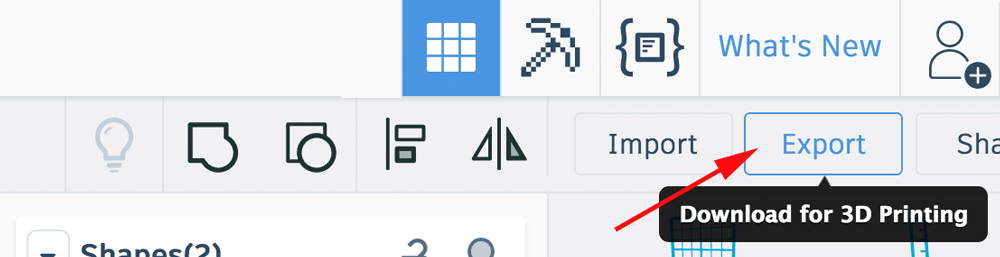

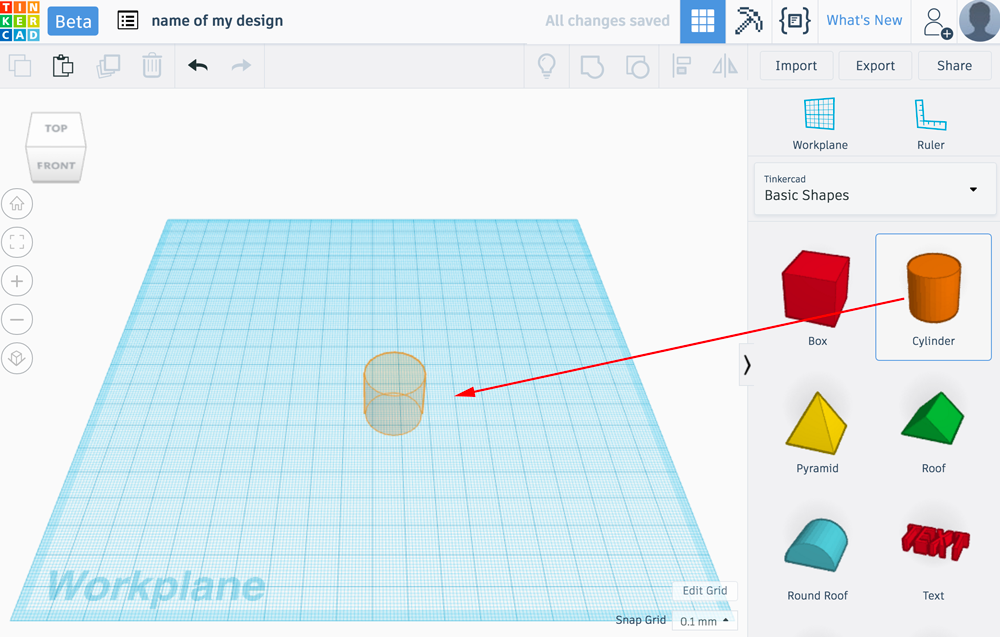

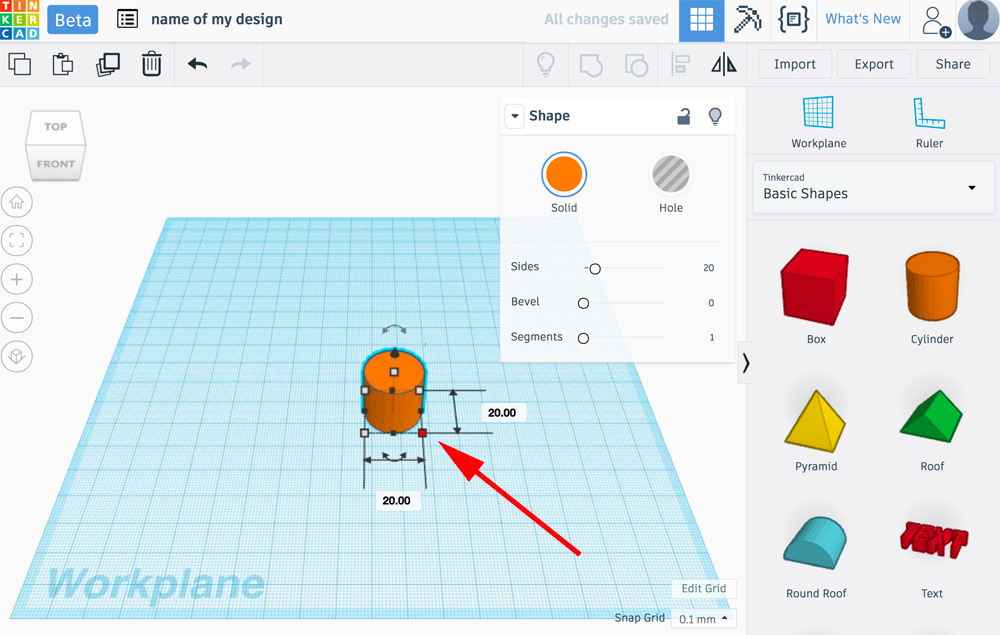

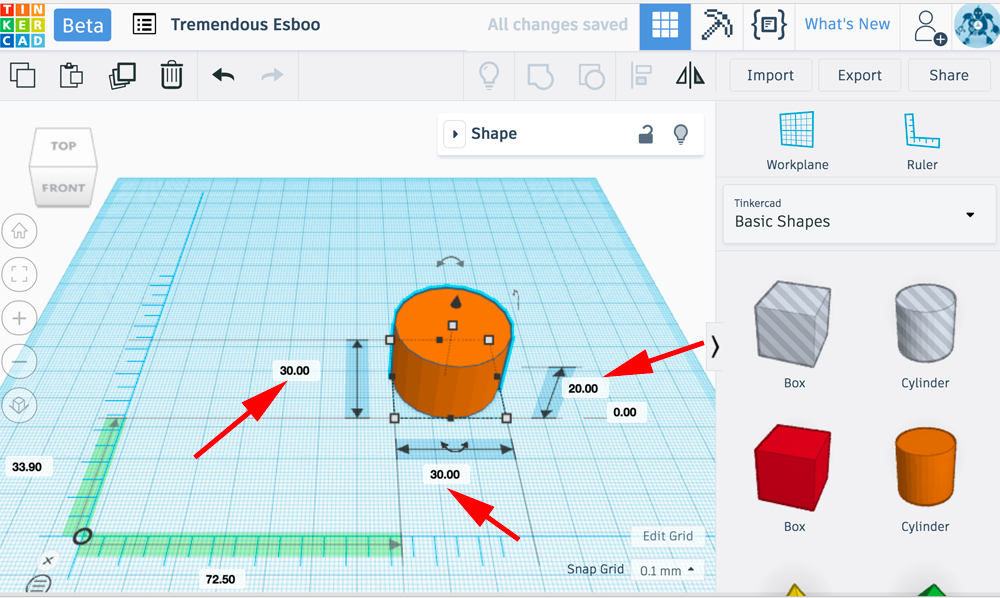

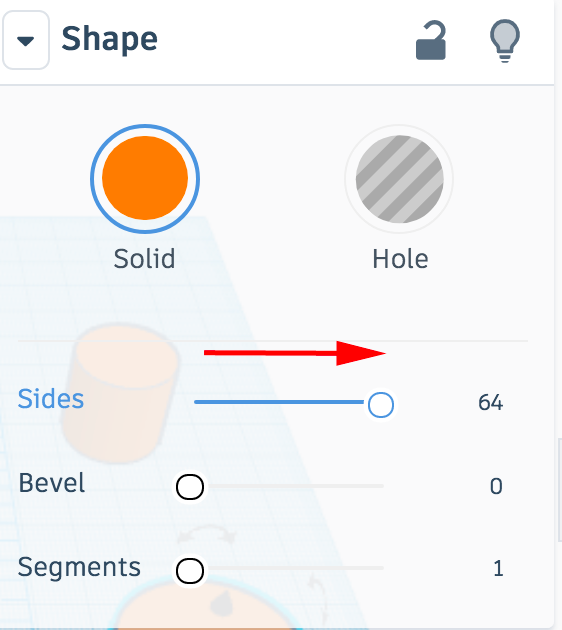

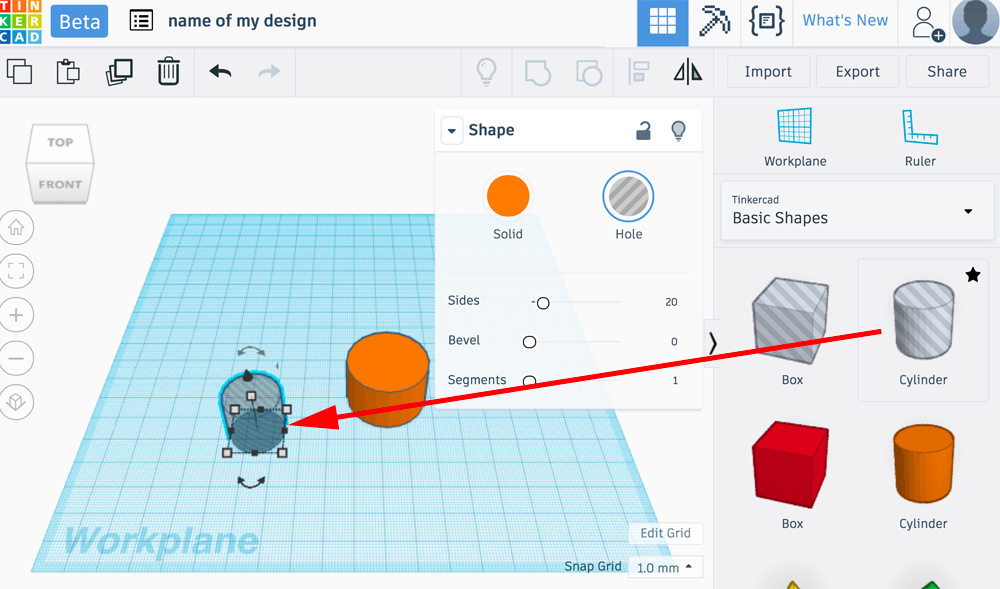

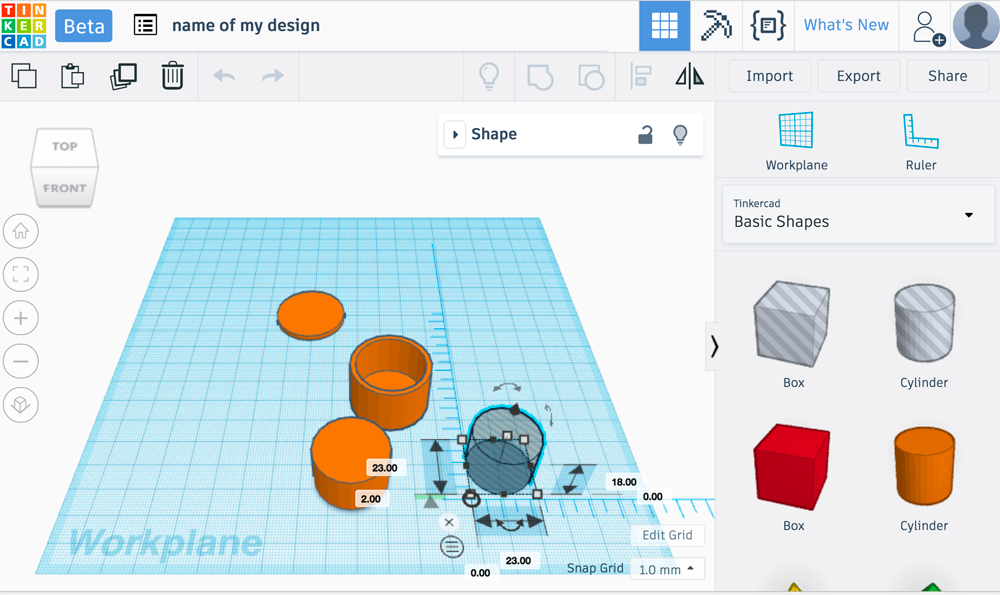

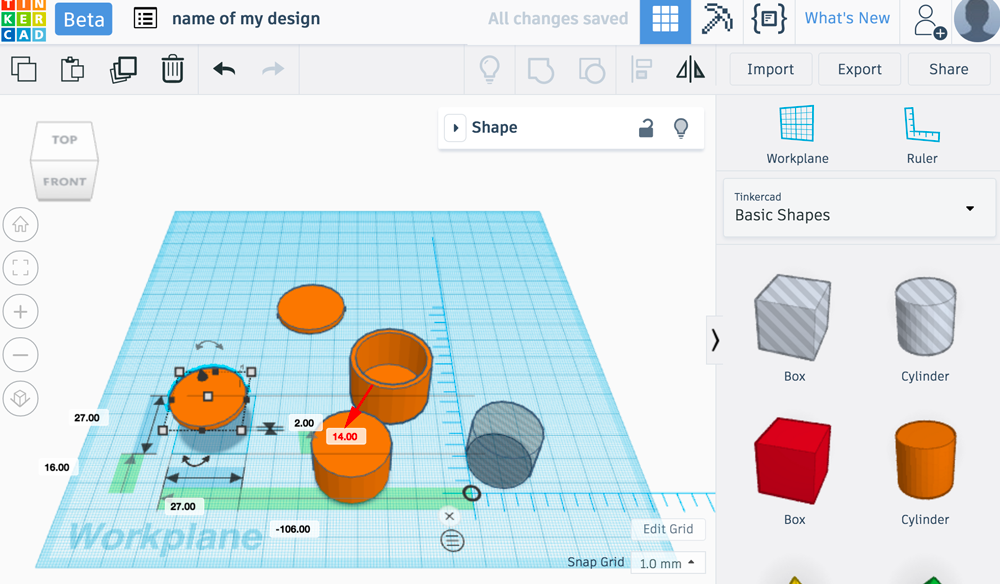

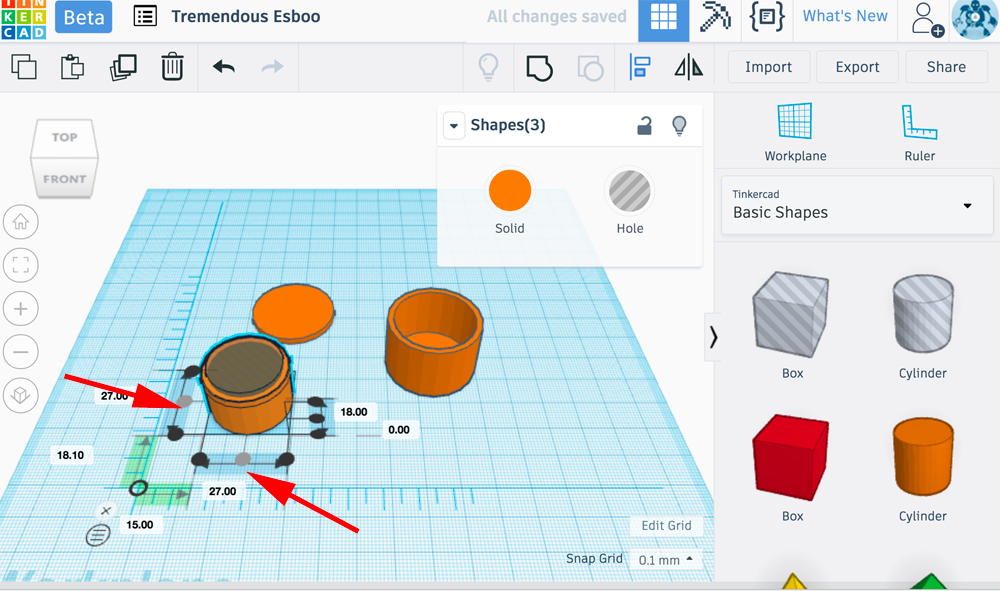

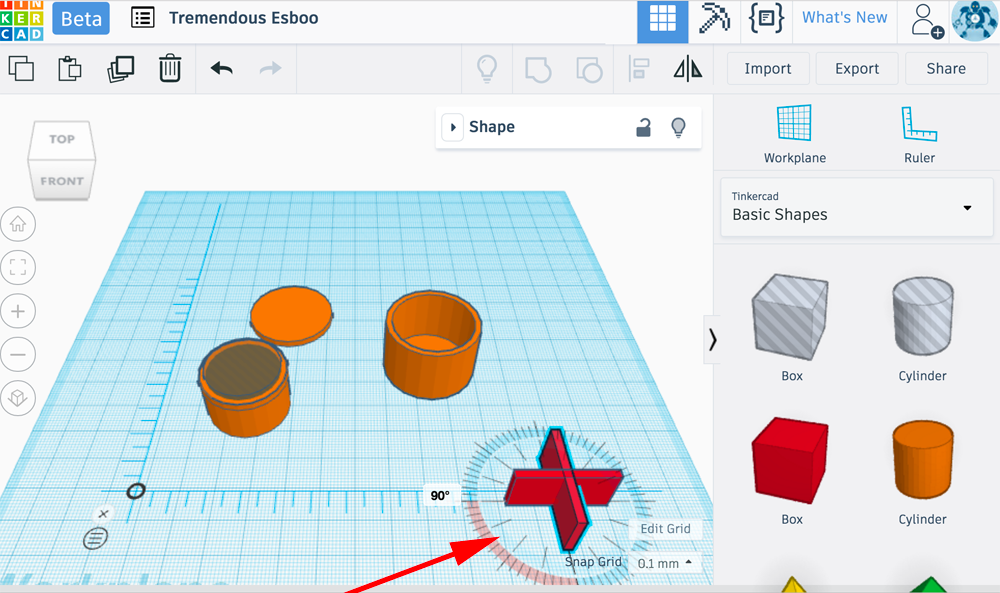

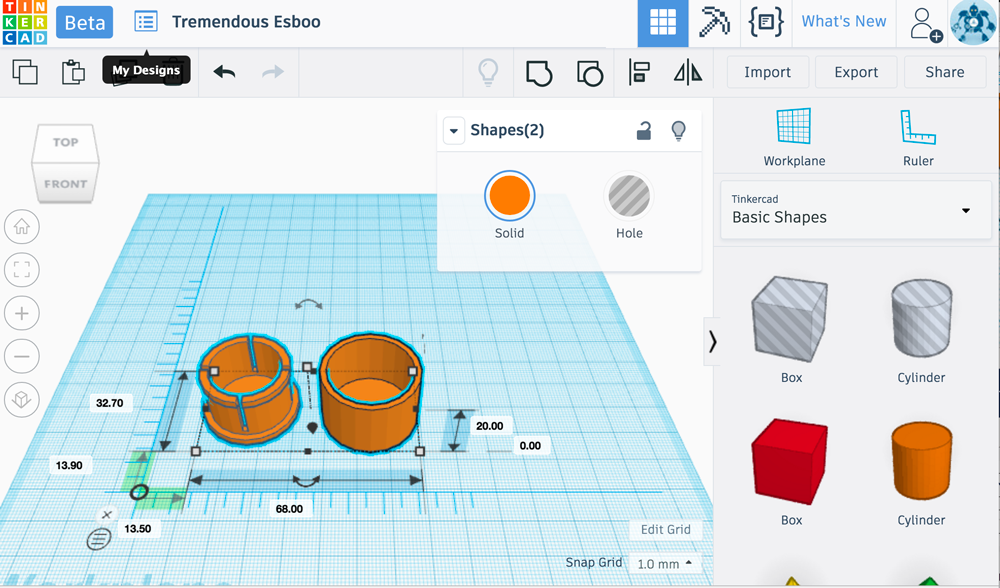

- Tinkercad is web-based computer-aided design (CAD) software from Autodesk for 3D printing. It is a great entry point for beginners, as it allows you to build your model from basic shapes. TinkerCAD also allows you to import SVG files and convert them into 3D models.

Click to open a Tinkercad Tutorial

Click to open Pill Box Tutorial